TOUGH GUN TT4E Reamer

Power Through Weld Spatter for Increased Uptime and Weld Quality With Ethernet Communications Reliability

The new TOUGH GUN® TT4E (ethernet) reamer robotic nozzle cleaning station from Tregaskiss is a robotic nozzle cleaning solution that maximizes uptime through superior cleaning performance, high durability components and features that allow quick and easy maintenance.

Enhanced by digital Ethernet communications that better integrate this unit into the digital controls infrastructure of your facility.

You’ll spend less time maintaining and troubleshooting your robotic welding equipment and more time getting product out the door!

Reduce Downtime, Safety Incidents and Costly Weld Defects Related to Anti-Spatter

Automating spatter removal extends the life of your robotic MIG guns and consumables, benefiting your production uptime, throughput and your bottom line.

more...

Configure My Gun

Reverse Lookup

Maximize Uptime With Superior Cleaning and Long Life

- Power through spatter to improve gas flow to reduce weld porosity in robotic applications

- .95 HP motor and 236 lbs. of spindle lifting force at 95 psi.

High Durability Components

- Powerful, lubricated motor lasts up to 18M cycles at 80+ psi

- Durable valves and cylinders rated for 10M+ cycles

- Wire cutter can run 1M+ cycles without requiring maintenance

NEW Anti-Spatter Reservoir With Increased Fluid Capacity

- A tethered cap and easy-clean filter help prevent anti-spatter contamination, which can lead to weld quality issues

- Larger 20-oz capacity increases uptime between refills

NEW Low Fluid Level Indicator

- Sends a signal to the PLC / robot when anti-spatter is running low

NEW Dedicated Motor Lubricator

- Maximizes performance and protects your investment by extending the life of the motor

- Highly recommended for use in damp and moisture rich environments

- Factory set for optimal pneumatic oil lubrication

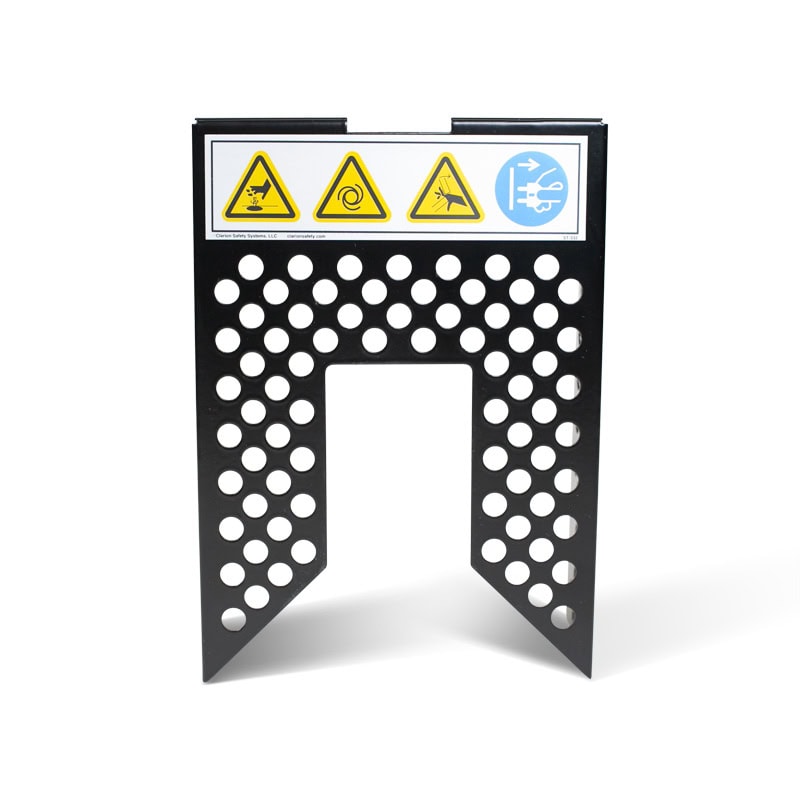

NEW Spray Containment Unit

- Reduces risk of slip / trip hazards due to overspray contamination

- Reduces downtime and costs for cell clean-up

- Easy to remove and clean

Purchase With Confidence

- Industry leading 2 year warranty can be increased to 3 years with exclusive use of TOUGH GARD® Anti-Spatter Liquid

Safe and Accurate Setup

- External setup switches allow independent operation of the sprayer, clamp and spindle during manual setup

- Cutter blade lifts into position but does not spin when activated by the spindle setup switch

Ease of Maintenance

- All wiring connections are built into the new wiring harness, reducing the risk of wiring errors during maintenance

- Wires are labeled for easy identification

Repeatability

- Spindle has rotating rod accuracy of 0.001″ – 0.004″ at its extended position for cutting repeatability and optimized spatter removal

- Fixed motor, clamp and v-block provide cutting accuracy and repeatability — No manual adjustments to nozzle clamps, cutter height, or motor height are required

Reliability

- Sprayer reservoir is located on the opposite side of the unit as an additional safeguard against overfilling / leakage onto internal electronics

- All pneumatic valves are internally mounted

- External setup switches are protected and seals protect points of entry

Double Capacity Anti-Spatter Reservoir — Now Standard!

- Tethered cap and easy-clean filter help prevent anti-spatter contamination which can lead to weld quality issues

- Larger 20-oz capacity increases uptime between refills

- Position of the anti-spatter reservoir is located on the opposite side of the unit is an additional safeguard against overfilling / leakage onto internal electronics

- Multi-feed compatible

New Fluid Level Indicator —

Now Standard!

- Sends a signal to the PLC / robot when anti-spatter is running low

Motor Lubricator — Now Standard!

- Dedicated motor lubricator maximizes performance and protects your investment by extending the life of the motor

- Highly recommended for use in damp and mositure rich environments

- Factory set for optimal pneumatic oil lubrication

New Spray Containment Unit — Now Standard!

- Reduces risk of slip / trip hazards and reduce cleaning downtime costs

- Easy to remove and clean

Smaller Size, Easier to Maintain

Compared to Tregaskiss TOUGH GUN® TT3/TT3E reamer models:

- 23% smaller footprint

- 7 lbs. lighter (minus optional accessories)

- Additional ease of maintenance features a tool-less entry and QR codes for immediate access to troubleshooting and other online resources

Purchase With Confidence

- Industry leading two-year warranty can be extended to 3 years with exclusive use of TOUGH GARD® anti-spatter liquid

New Reamer Shroud

- Comes standard on new reamers configured specifically for use in cobot welding applications

- Can be retrofitted to existing TOUGH GUN® TT4 reamers, but please note additional components are required for units manufactured before March 2024

New Wire Cutter Shroud

- Comes standard on new TOUGH GUN® TT4 reamers equipped with the wire cutter option when configured specifically for use in cobot welding applications

- The wire cutter is now available for purchase with or without the wire cutter shroud

Customize your TOUGH GUN TT4 Reamer online

Now you can get access to additional resources and an expanded replacement parts list with diagram when you configure the gun part number you need or reverse lookup your existing gun part number.

This new mobile-friendly online configurator provides downloadable exploded view diagrams and other valuable takeaways that you can print, save in PDF format, or share via email.

Check it out today!

Specifications

- Rated Voltage: 24VDC

- Operating voltage: ±10% of rated voltage

- Power consumption: max. wattage in operation 5.3W

- Air requirements: 80 to 100 psi (5.0 to 7.0 bar) at 16 CFM (7.5 L/s)

- Air motor (at min. air requirement): stall torque at 80 psi (5.5 bar) = 83 in.-lbs. (9.4 Nm)

- Anti-spatter requirements: use only water-based anti-spatter liquid

- Weight: ≅ 41 lbs. (18.6 kg.)*

- Product dimensions (L x W x H): 13.74″ x 10.36″ x 22.18″ (349 mm x 263.2 mm x 563.4 mm)*

- Operates in any position

Standard Features

- Anti-spatter reservoir

- Fluid level indicator

- Spray containment unit

- Dedicated motor lubricator

- Reamer shroud (when configured for use in cobot welding applications)

Optional Features

Compatibility

*The optional features are sold separately or added as options when ordering, and can change the weight and physical dimensions of the product.

Software Downloads

Programs

Software

Reamer Shroud

Ideal for use in cobot welding applications, the new reamer shroud encourages safety where the operator could be near the reamer during operation. All new reamers configured specifically for use in cobot welding applications come standard with a factory-installed reamer shroud.

TOUGH GUN TT4 reamers can be retrofitted with the reamer shroud, but if converting a reamer that was manufactured prior to March 2024, additional components will be required. Contact our Technical Services team for additional assistance if required.

TOUGH GUN Wire Cutter

The TOUGH GUN wire cutter removes the ball-end of the welding wire to provide smooth arc starts and consistent wire stick-out. The TOUGH GUN wire cutter easily cuts a variety of wire types from stainless steel to aluminum to flux-core in wire sizes up to 1/16″.

Wire Cutter Shroud

The new wire cutter shroud is ideal for use in cobot welding applications where the operator could be near the wire cutter during operation. The TOUGH GUN wire cutter is available with or without a wire cutter shroud, but when configuring a new reamer with the wire cutter option specifically for cobot welding applications, the wire cutter shroud comes factory installed.

Spray Containment

The innovative spray containment unit from Tregaskiss helps prevent air contamination by catching anti-spatter overspray in its sealed basin, improving the air quality of the working environment and maintaining the cleanliness of the weld cell.

Filter / Regulator

The Filter / Regulator unit from Tregaskiss is another recommended accessory that helps extend the life of your TOUGH GUN reamer. The filter cleans the air supply to the reamer and restricts debris from reaching the motor, keeping it uncontaminated and ensuring maximum performance and longer life, while the regulator works to ensure optimal air pressure is achieved at the unit.

Nozzle Detection

Nozzle detection for the TOUGH GUN TT4E reamer uses a proximity sensor mounted on the side of the reamer that can be used independently of the ream cycle. The robot positions the front end of the MIG gun close to the sensor to detect the presence of the nozzle. If the nozzle is not present, a signal is then sent back to the robot controller or PLC.

Tregaskiss Cutter Blades

Tregaskiss is pleased to announce improvements to the design of our cutter blades. These new cutter blades are engineered from harder, stronger material for enhanced performance and durability, making them more resistant against breaking, snapping, chipping or cracking.

Tregaskiss V-Blocks

Compatible with Tregaskiss® and most competitive consumables, these four-sided v-blocks ensure your cutter is concentric with your consumables and your nozzle bore to guarantee the most effective ream. Choose from five available v-block options when configuring your new TOUGH GUN TT4E reamer.

TOUGH GUN Reamer Stand

Custom Height. Quick Installation. Easy on the Budget.

Tregaskiss provides a simple fixed height durable stand for all TOUGH GUN TT4A and TT4E reamer models.

TOUGH GUN Reamer stands are available in heights between 18 and 36 inches in 6-inch increments.

TOUGH GARD Anti-Spatter Liquid

TOUGH GARD anti-spatter liquid was developed to address the performance requirements of metal fabricators. TOUGH GARD anti-spatter liquid won’t harm machinery or clog the sprayer like oil-based anti-spatter solutions, it cleans up easily with no residue, it’s safe to use and it’s safe for the environment. Helping prevent spatter adhesion and extending the life of consumables, TOUGH GARD anti-spatter liquid reduces downtime thus lowering operating and maintenance costs.

TOUGH GARD Multi-Feed System

The TOUGH GARD multi-feed system for anti-spatter solution can connect up to ten TOUGH GUN TT4 reamer stations. This system eliminates the need to refill anti-spatter reservoirs on a frequent basis, resulting in lower operating costs, reduced downtime and increased safety.