The New Clean Air E™ Fume Extraction MIG Gun Offers Superior Fume Capture, Enhanced Ergonomics

Up to 95% fume capture efficiency and optimized design make workspaces safer and reduce welder strain

For Immediate Release

BEECHER, Ill./WINDSOR, Ontario (March 20, 2025) — Bernard announced the release of the new Clean Air E™ fume extraction MIG gun, the newest high-efficiency fume extraction gun in the brand’s lineup. Crafted for efficient extraction, enhanced ergonomics and engineered endurance, this gun sets a new standard in MIG welding fume capture technology.

With an ongoing priority to ensure safer, cleaner work environments for operators coupled with heightened fume standards being implemented across the country, Bernard saw an opportunity to evolve the standard fume extraction gun to maximize its efficiency and usability. Bernard took customer and welder feedback and designed a product that would be the most impactful for welders in a next-generation fume extraction gun. The team applied that feedback throughout the research and development process until it resulted in the Clean Air E™, which offers solutions to common operator pain points, including:

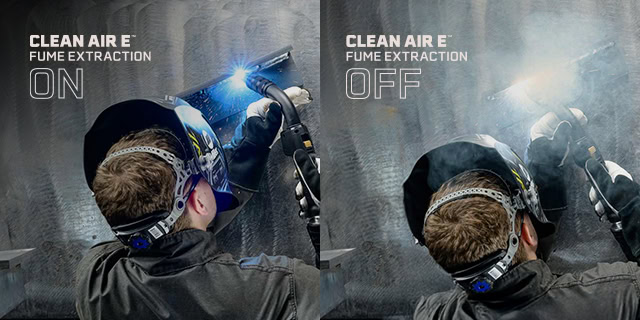

· Efficient extraction: The Clean Air E™ achieves up to 95% fume capture right at the source, which improves air quality in the workspace and reduces OSHA-related risks.

· Enhanced ergonomics: The ergonomic design reduces strain and fatigue on welders, which allows them to focus on precision and quality for extended use.

· Engineered for endurance: The Clean Air E™ features durable components and long-life consumables, which reduces downtime and maintenance costs, delivering a lower cost of total ownership.

“When it comes to welding, operators seek the trifecta in their gun: ergonomics, extraction performance and ease of maintenance,” said Jerome Parker, product manager, Bernard. “The Clean Air E™ was designed alongside actual users to ensure we arrived at a solution that redefined traditional fume capture guns for the modern welder, enhancing both their operator experience and their weld environment.”

On the gun itself, the Clean Air E™ offers enhanced features for easier and more efficient use:

· Improved weld access: Three nozzle shroud lengths allow operators to balance fume capture with weld access and improved visibility of the weldment.

· Instant flow adjustment: The new flow control slide on the back of the handle enables welders to easily reduce airflow by up to 10 cfm to help overcome porosity issues.

· Upgraded handle comfort: Two handle styles are available to suit different grip styles and hand sizes, with internals contoured to enhance airflow and fume capture. The lever trigger can also be mounted on top for additional comfort.

· Increased flexibility: A durable, lightweight aluminum ball swivel at the end of the handle provides 15 degrees of extra flex in any direction for additional improved ergonomics.

· Maximized airflow: A new Y-connector offers contoured internals that maximize airflow, with a vacuum outlet that is compatible with any fume extraction unit. For a premium fume extraction pairing, operators have the option to connect the Clean Air E™ to the Miller® FILTAIR® 215.

Learn more about how the Clean Air E™ can deliver safety, performance and comfort for welders at https://www.startsatthesource.com/

About Bernard Bernard, a leading manufacturer of premium semi-automatic MIG welding guns and consumables, is dedicated to enhancing welding productivity and performance. Headquartered in Beecher, Illinois, Bernard is known for innovative solutions that prioritize operator comfort, ease of maintenance, and exceptional durability. Bernard is a proud brand of Illinois Tool Works Inc. (NYSE: ITW). For more information, visit BernardTregaskiss.com, call 1-855-MIGWELD (1-855-644-9353), email CS@itwmig.com.

Contact: Lauren Smith, Hiebing for Bernard/Tregaskiss phone: +1 6082684408 lsmith@hiebing.com

Features and Benefits of the Clean Air E™

Features and Benefits of the Clean Air E™

Discover the Clean Air E™ difference.

Superior Fume Control Right at the Source With up to 95% source fume capture efficiency, the Clean Air E minimizes airborne contaminants, protects your team, and improves visibility on every weld. It helps you meet stringent compliance standards without compromise. Effortless Ergonomics for Extended Use Designed for welders, the Clean Air E features a balanced build, optimized handle design, and a ball swivel for added flexibility. This reduces strain and improves control, focusing on comfort and efficiency to help welders stay productive through long shifts. Industrial-Grade Durability, Reduced Downtime Built for heavy-duty use, the Clean Air E is engineered to last. Its rugged design, combined with long-life consumables, reduces maintenance demands and lowers total costs, keeping your team welding without interruption. Enhanced Visibility for Precise Welds Clearer sightlines mean better welds. The Clean Air E is designed to minimize arc obstructions, providing improved visibility and weld access. With a better view of the weld puddle, welders can work with greater accuracy, control, and consistency.

Want to learn more? Click here.

Bernard and Tregaskiss Release NEW MIG Welding Guns & Consumables Catalog

Bernard and Tregaskiss Release NEW MIG Welding Guns & Consumables Catalog

BEECHER, Ill./WINDSOR, Ontario. (March, 2023) — Bernard and Tregaskiss have announced the availability of a joint MIG Welding Guns & Consumables catalog.

The 46-page, full-color catalog includes a consumable comparison chart to compare contact tip, nozzle and diffuser types across the brands’ available consumables offerings, along with a consumables and MIG gun series compatibility chart to guide users in their selection.

The catalog offes easy-to-read key features and part numbers for its products and is organized by product category, first highlighting the brands’ exclusive AccuLock™ S and AccuLock R Consumables — both designed to reduce downtime and improve welding performance.

Also included in the catalog are product details and configurator overviews for customizing Bernard® Semi-Automatic MIG Guns, Tregaskiss® Robotic MIG Guns, Clean Air™ Guns and more. Tregaskiss Fixed Automatic MIG Guns for hard tooling applications are also featured.

Each page includes website quick links with URLs users can visit to learn more about a specific product, plus service and support contact numbers and directions to explore online resources, such as videos and product configurators.

The catalog can be downloaded as a PDF or ordered as a printed copy at Tregaskiss.com/literature.

PRODUCT CHANGE — AccuLock™ Conventional Liner Gas Diffusers

PRODUCT CHANGE — AccuLock™ S Conventional Liner Gas Diffusers — O-Ring Color Change to Gray

All AccuLock S conventional liner gas diffusers began shipping with a gray o-ring instead of a black o-ring on February 22, 2023. The gray o-ring makes it easier to tell the difference between an AccuLock S dual-locked liner gas diffuser and an AccuLock S conventional liner gas diffuser.

For reference, the AccuLock gas diffuser part numbers listed below will be assembled with a gray o-ring:

| Part Number | Description |

| D-A1-C | AccuLock S Gas Diffuser, Large Nozzle, Thread-On, Conventional Liner |

| D-A2-C | AccuLock S Gas Diffuser, Large Nozzle, Slip-On, Conventional Liner |

| DS-A1-C | AccuLock S Gas Diffuser, Small Nozzle, Thread-On, Conventional Liner |

| DS-A2-C | AccuLock S Gas Diffuser, Small Nozzle, Slip-On, Conventional Liner |

Product Improvement – LSR+ (Plus) Unicables

PRODUCT IMPROVEMENT –

LSR+ Unicables with SmoothTurn™ Technology

October 11, 2022

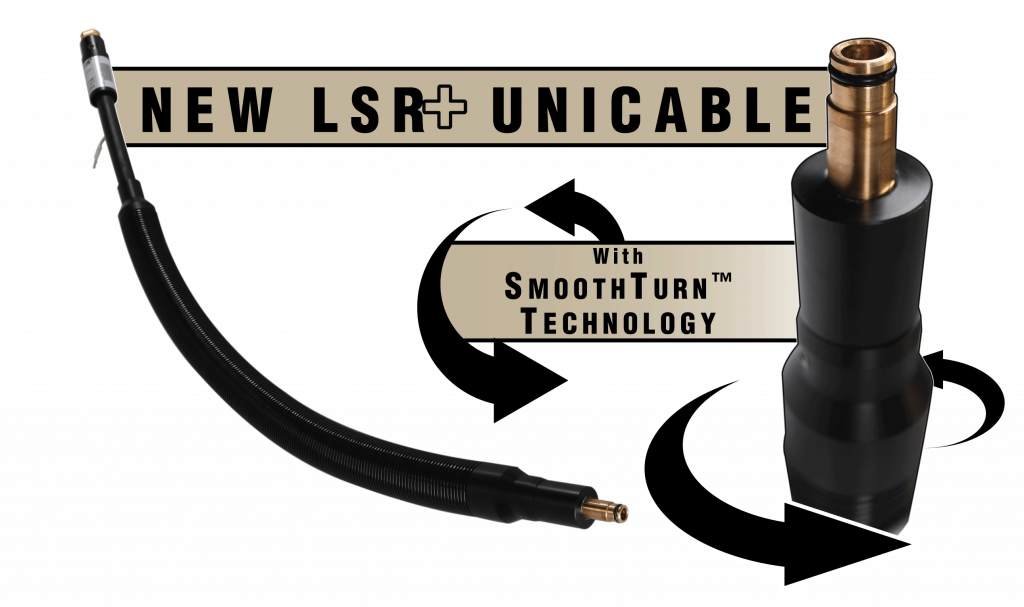

For use with TOUGH GUN® TA3 ThruArm® series robotic MIG guns, LSR+ (Low-Stress Robotic) unicables incorporate new SmoothTurn™ technology to maximize production uptime.

Conventional style unicables typically come with a connection that limits rotational capabilities and produces torsional stress in the cable. Unlike conventional unicables, the LSR+ incorporates a rotating power connection that reduces this stress during rotation. Additionally, a protective external conduit contributes to cable longevity by shielding components from harsh welding environments.

Stress Relieving Features

- SmoothTurn Technology reduces frictional forces on internal components increasing overall cable life up to 300%

- Enhanced electrical connections provide a more stable arc, resulting in less spatter and longer cable life

- Unique internal components improve support and bend radius of the cable during heavy robot articulation