[…] the robot to the tip of the robotic MIG gun) so maneuvering around tooling and gaining joint access becomes less cumbersome. There are also more options for neck lengths and angles available for robotic MIG guns, which helps companies gain access to complicated joints. More cooling options Because many robotic welding applications tend toward […]

[…] lead to poor welding performance and possibly a shorter life span. It is not uncommon for some welding operators to place the whole MIG gun nozzle and neck into a metal tube for storage. However, this practice puts extra force on the nozzle and/or front end of the gun each time the welding operator […]

[…] If the tool center point is off, look first to make sure no other damage occurred to another component during the crash. It could indicate that the neck bent out of position, for example, and needs to be straightened with a neck checking fixture or replaced. If all components are undamaged and the deflection is […]

[…] impact Tool Center Point (TCP) and cable life – please see Configuration Comparison Chart below for both solid mount and clutch mount setups with a short 45-degree neck for reference. Details For each model above, when a TOUGH GUN TA3 MIG gun is configured through Tregaskiss, the complete torch solution is Tregaskiss branded and […]

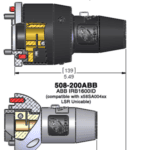

[…] is the replacement for 508-200ABB connector housing, this unit will change tool center point (TCP) by approximately 1.428″. For those customers using a 508-200ABB with a 405-22QC neck, we will be able to develop a special 22-degree neck for use with the A58G1S module to match their existing TCP. However, due to a length […]

[…] cell layout is not optimized, it can negatively impact those goals — along with the quality of the completed welds. Poor cell layout can create a bottle neck in the process or result in parts not being properly welded —problems that cost time and money in the long term. When considering proper layout for […]

[…] customizable according to robot make and model, most TOUGH GUN TA3 robotic MIG guns can be configured with the desired solid or clutch mount/wire brake/air blast combinations, neck, nozzles, contact tips and more at Tregaskiss.com/ConfigureMyGun. The guns have been designed with precision and reliability in mind and feature the unique low-stress robotic (LSR) unicable, […]

[…] to prevent “trigger finger”. This is caused by applying pressure to a trigger for an extended period of time. 2. Using a MIG gun with a rotatable neck to help the welding operator move more easily to reach a joint with less strain on the body. 3. Keeping hands at elbow height or slightly […]

[…] on the handle or missing screws. Check that the gun trigger is not sticking or otherwise malfunctioning, and replace these components as necessary. • Check the gun neck. Loose connections at either end of the neck can cause electrical resistance that leads to poor weld quality and/or consumable failures. Also, visually inspect the insulators […]

[…] arc length, both of which increase the voltage in the application and the overall temperature. The result is, again, more radiant heat. Using a longer MIG gun neck can help minimize the impact of radiant heat on the handle by placing it further from the arc and keeping it cooler. The consumables you use […]

[…] size can be matched regardless of the welding wire drum or spool size. The AccuLock™ S consumable system provides error-proof liner replacement. The liner loads through the neck at the front of the gun and is locked and trimmed flush with the power pin at the back of the gun, which eliminates the need […]

[…] time producing parts. Reliability The BA1 cobot MIG gun has metal-to-metal keyed connections to hold it in place in the mounting arm. These also keep the aluminum-armored neck firmly connected to the gun, so users can depend on the gun to perform consistently. Simplicity The gun is easy to maintain when needed — necks […]

[…] related parts and consumables to a minimum. BTB Air-Cooled Guns optimize productivity, welder ergonomics and weld access. Operators can customize this gun line with a variety of necks, handles and trigger styles. Its industrial-grade performance and reliability withstands demanding and abusive environments. TGX® XS Series Air-Cooled Gun is perfect for low volume, light- to […]

[…] eliminate the need for water-cooled guns, which can be more complex and expensive to maintain. However, hybrid air/water-cooled designs incorporate water cooling on the front of the neck with an air-cooled cable. This design is good for applications with borderline air-cooled duty cycles that experience a higher frequency of consumable changeover. The hybrid gun […]

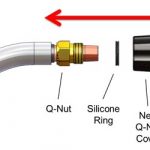

[…] Bernard® semi-automatic MIG guns BTB platform launching on June 2, 2014, Bernard is pleased to announce the launch of the improved Q-Nut used on all Bernard rotatable necks. It has been completely redesigned to offer a significant increase in durability. Please note that the new silicone ring, Q-Nut cover and silicone insulator are now […]

[…] GUN® TA3 gun connector housing to accommodate an additional setscrew (see ‘Setscrew 2’ in Figure 2) which is designed to improve TCP repeatability when using long/extended length necks by providing additional support to help secure the neck firmly in place. In order to make this change, extra thread engagement was required for the front […]

[…] (or gas diffusers). These consumables generally have less mass and are less expensive than their heavy-duty counterparts. Similarly, because they are designed for short arc times, the necks (or goosenecks) on light-duty MIG guns are made of lightweight materials, including polymer, rubber or light aluminum armor. The strain relief and connections on light-duty guns […]

[…] production — when the robot finishes welding a part or during routine contact tip changeover, for example — check for clean, secure connections between the MIG gun neck, the diffuser or retaining heads and the contact tip. Also, check that the nozzle is secure and any seals around it are in good condition. Having […]

[…] our TOUGH GUN ThruArm™ G1 and G2 series platforms – including our low-stress robotic (LSR) unicable – along with new features for increased strength and durability. Re-engineered neck clamp improves durability and consistency of clamping force Additional standard necks expand the tool center point options and variety of working envelopes Direct replacement for TOUGH […]

[…] electrical contact and reduce CTWD variability. The wire’s cast is affected by three main factors: the supply reel (spool or drum); drive roll tension; and MIG gun neck angle. A tight wire cast may allow for a looser bore tolerances and still be able to make the appropriate electrical contact with the contact tip […]

[…] or for long durations of welding. They are available in the marketplace in both air- and water-cooled models (discussed below) ranging from 400 to 600 amps. The necks on these guns are often longer, which creates more distance between the welding operator and the high heat from the arc, and the handles on these […]

[…] finish. This change is purely aesthetic, and has no impact on performance, part numbering or price. OLD Chrome Finish NEW Black Finish Click here for more information about the Clean Air™ fume extraction gun. Clean Air Fume Extraction MIG gun with old chrome neck Clean Air Fume Extraction MIG gun with new black neck

[…] power cable, to save time and money in the long run and keep the operation running smoothly. Image of Tregaskiss TOUGH GUN CA3 robotic MIG gun with 45 degree neck TOUGH GUN TA3 Robotic Air Cooled MIG Gun Image of end of LSR unicable for through arm robotic welding guns with arrows demonstrating rotational movement

[…] Features and Benefits: Adjustable nozzle shroud location Vacuum chamber on front adjusts to one of four positions to optimize fume capture, gas flow and weld access Additional neck options 30-, 45- and 60-degree neck options now available for the curved handle model Now available with Centerfire™, Quik Tip™ and TOUGH LOCK® consumables Compatible with […]