[…] A robot integrator can conduct a 3D simulation using models provided by the robotic welding gun manufacturer through computer-aided design (CAD) to make sure the gun and neck have the proper access and reach within the given space. The CAD model can also show whether the selected gun has the correct tool center point […]

[…] Because MIG guns have few moving parts and are relatively simple to inspect, you should check the connections between the wire feeder, the cable, the gun, the neck and the consumables on a daily basis to ensure they are tight and undamaged. A loose or damaged fitting can create resistive heat build-up, poor weld […]

[…] comfort and ergonomics, gun performance and ease in producing quality welds. When choosing and configuring a fume extraction gun, consider these options: Tailoring the gun handle and neck to the application and welder preferences can help improve weld pool access and reduce operator fatigue. Most guns are available in curved and straight handle options. […]

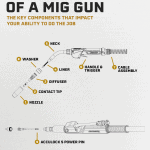

[…] Choose Wisely Selecting high quality consumables is paramount to obtaining high quality welds and avoiding unnecessary downtime. MIG gun consumables consist of a diffuser, closest to the neck, a contact tip, and a nozzle, all of which serve unique functions in delivering current to the wire and shielding gas to the weld pool High […]

[…] misshape the nozzle, rendering it unusable. Keep Connected Look for consumables with a tapered design that locks conductive parts — like the contact tip, gas diffuser and MIG gun neck — together. Good welding performance depends on good electrical conductivity. Look for consumables with a tapered design that locks conductive parts — like the contact tip, […]

[…] welding operators to request feedback during the trial. According to Jerik, welding operators saw noticeably less consumable consumption. However, they wanted to change the angle on the neck of guns to gain better access to some difficult joint configurations. They worked back and forth with Bernard to determine a different angle of the neck […]

[…] so much that he sought out an option for his gas-shielded applications. The result? With the help of Stubblefield, he customized a Bernard Q-Gun with the exact neck, consumables and cable length for his applications. (Bernard allows customers like Jolson to create their own style MIG Gun with their online Configurator or by working […]

[…] life (up to 2x) and ease of serviceability New dual layer cable outer jacket, re-engineered cable guide and increased copper content contribute to extended service life Re-engineered neck clamp improves durability and consistency of clamping force Additional standard necks and mounting arms expand tool center point options and working envelopes Direct replacement for TOUGH […]

[…] pumps cooling solution from a radiator unit, usually integrated inside or near the power source, through hoses inside the cable bundle, and into the gun handle and neck. The coolant then returns to the radiator, where a baffling system releases the heat absorbed by the coolant. The ambient air and shielding gas further disperse […]

[…] and front-loading liners may come with a plastic liner trim gauge. This can be fed over the top of the liner and pressed up flush against the neck, so the liner can be trimmed to the end of the gauge. If no gauge is provided, please consult your MIG gun manual or manufacturer’s website […]

[…] larger cables necessary to provide the higher amperages. The guns frequently use heavy-duty front-end consumables that are capable of withstanding high amperages and longer arc-on times. The necks often are longer as well, to put more distance between the welding operator and the high heat output from the arc. Cooling options: air vs. water […]

[…] should also be secure. It’s especially important to check and tighten all connections after a gun has been serviced or repaired. A loose contact tip or gun neck is an invitation for gun failure at that spot. When connections aren’t tight, heat and resistance can build up. Also, be sure any trigger connect being […]

[…] most interruptions in conductivity. These include: the connection between the power source and the gun’s power cable plug; the fittings and connections between the gun’s power cable, neck, diffuser, contact tip and welding wire; and the connections between the work lead, welding table and power source. Routinely check these connections before problems arise in […]

[…] The best way to resolve this issue is to keep the conduit as straight as possible and use the shortest run feasible. 2. Incorrect robot positioning and neck selection Many large companies, such as tier-one automotive suppliers, measure their efficiency based on available square footage, so placing many robots in an area is common. […]

[…] the exact MIG gun necessary, many manufacturers have moved toward configurable products. Typical configurator options include: amperage, cable type and length, handle type (straight or curved), and neck length and angle. These configurators also offer the option to select the type of contact tip and MIG gun liners. Upon selecting the desired features for […]

[…] properly trimmed so that it fits as tight as possible to the other components. Some liners require no measuring for error-proof installation. After being loaded through the neck of the gun, these liners are locked in place and concentrically aligned with the gas diffuser and the power pin. This creates a perfectly aligned and […]

[…] and determine how far it has moved from the original programmed settings. If a gun is determined to be out of the acceptable TCP range, the gun neck can be removed and recalibrated offline to factory specifications with a neck straightening fixture. Some systems also provide the capability to adjust TCP automatically with the […]

[…] while simultaneously protecting internal components of the gun from heat and spatter. 2. Contact Tip The contact tip guides the wire and transfers the current from the neck through the filler metal and to the work surface. Consistent wire feeding ensures a stable arc and high weld quality. 3. Diffuser The diffuser conducts electricity […]

PRODUCT UPDATE — ACCULOCK™ S Consumables and New Neck on XS180 AND XS 260 TGX™ Series MIG Guns We are pleased to announce that on March 1, 2024, we started offering XS180 and XS260 TGX (10’ and 15’) MIG guns with Bernard neck, silver color (part number 205-60) and AccuLock™ S consumables with Bernard® […]

NEW! Ideal for shipbuilding and construction industries to reduce downtime and increase productivity! NEW! Locked rotatable neck eliminates downtime at start of shift due to missing necks resulting in reduced operator costs Locked rotatable neck is easily serviceable by maintenance Steel monocoil power cable is […]

Save Money, Improve Performance with Bernard® Replaceable MIG Gun Parts Taylor Machine Works saves money and improves performance by welding its forklifts with Bernard MIG guns. All Bernard MIG gun parts are replaceable, and the necks adjust to fit tight joints. “You can put different necks on the guns. Those twisty necks, I call them. […]

[…] as it may help reduce wrist fatigue and be easier to maneuver into complex joints. You may also want to consider looking for a specific style of neck for your application. Many GMAW gun manufacturers offer fixed, rotating and flexible necks in various lengths and angles, allowing you to reach joints more easily. Regardless […]

[…] pin, based on their specific needs. The Configurator can then be used to request a price quote from the company’s nearest welding distributor. “You can have different neck lengths, different bends and other options that allow it to fit into almost any position we need it to get into,” Exner said, noting that his […]

[…] there are still a few hand-held guns of a third brand that are still in service, but will be replaced with Q-Guns once they wear out. Rotatable necks increase operator comfort and weld accuracy by allowing the operator to adjust the position of the gun rather than his body to accommodate the welding joint. […]