Black polymer armored MIG gun necks contain a thick copper wall with a conductor tube interior, so they don’t radiate or reflect heat as quickly. Optimizing MIG welding gun performance in specific applications can be a matter of choosing different components for the gun. Selecting the […]

The durability of the gun neck — and especially its ability to withstand impacts — is important for maintaining tool center point (TCP). A robotic MIG welding system contains many components that impact the quality of the parts it welds, its productivity and […]

[…] from start to finish. Watson Engineering, Inc. of Taylor, Mich. is just such a one. Tregaskiss’ TOUGH GUN™ I.C.E. Robotic MIG gun has helped Watson minimize downtime for neck changeover, and it offers the welding capacity to weld on a variety of parts and part thicknesses. What began as a one-person fabrication shop nearly thirty […]

A welding gun’s handle, neck and power cable design all can significantly impact the duration of time a welding operator can weld without experiencing fatigue or stress. Knowing the available options are key to improving comfort and efficiency. Taking into account the heat, the repetitive motions […]

[…] suited for long weldments. These GMAW guns operate by circulating coolant from a radiator unit through the power cable via cooling hoses and through the gun and neck. This coolant returns to the radiator where it releases the heat that it absorbed during the welding process. Because of the water circuit, there is the […]

[…] longer gun life thanks to reduced equipment stress. Simulation programs can be used to determine proper system setup, including TCP requirements and which nozzle and GMAW gun neck are best suited to get the desired joint access or angle. The reach and access of the gun neck, in particular, is an important factor in […]

[…] of a curved style handle. Another important factor in maintaining a good comfort level for the welding operator is selecting a MIG gun with the appropriate handle, neck and cables for the application. Typically, as a MIG gun’s amperage decreases so too does the size of the gun handle and the cable, which makes […]

[…] joints with a MIG, flux-cored or fume extraction welding gun and facing a hot arc, the term takes on an especially important meaning. A welding gun’s handle, neck and power cable design can significantly impact the duration of time a welding operator can weld without experiencing fatigue or stress. So too can the heat […]

[…] cases customizing the gun — is a critical way to impact welding operator comfort so he or she can achieve the best results. A gun’s trigger, handle, neck and power cable design all help determine how long a welding operator can comfortably weld without experiencing fatigue or stress. The application’s weld joint geometry also […]

Beginning on June 2, 2014, Bernard’s new BTB MIG gun platform brings our Q-Gun™, S-Gun™ and T-Gun™ semi-automatic air-cooled MIG guns into a single gun line and single configurator. As a part of this launch, all fixed and rotatable necks offered through the new BTB […]

PRODUCT UPDATE – Neck Insulator Selection for BTB MIG Guns Although no new neck insulators are being introduced due to implementation of the BTB semi-automatic air-cooled MIG gun platform on June 2, 2014, users should be aware that neck insulator replacement for these guns will be based on several variables including: Your gun’s amperage; […]

[…] always to have the shortest cable possible that still meets the needs of the application to avoid unnecessary coiling. The length and bend angle of the gun neck are also factors based on the available workspace and joint access. Remember, it is easier to make design choices like these up front rather than make […]

[…] mounted on a nozzle station (to be discussed later) or remotely located to be used as needed. Inspected and Ready to Weld Another key peripheral is a neck (or gooseneck) inspection fixture. A neck inspection fixture tests the tolerance of a robotic MIG gun’s neck to the tool center point so it can be […]

[…] proper storage and handling doesn’t just lower your actual costs for consumables, it can also prevent weld defects that require costly rework. Tip No. 2: Get a Neck Up Choose the most appropriate neck for your MIG welding application in order to increase comfort and control, and save money. Rotatable necks, for example, adjust […]

[…] the robot arm. If you are experiencing inconsistent welds or welds that are off-location, this may stem from a problem with TCP. If the robotic MIG gun neck is bent or damaged during a collision in the weld cell, this can result in TCP issues. Use a neck-checking fixture or neck alignment tool to […]

[…] In conjunction with a wire brake, the wire cutter can ensure that the stick-out remains consistent for robots with touch sensing capabilities that help locate the joint. Neck inspection fixtures Another key peripheral is a neck inspection fixture, which tests the tolerance of a robotic MIG gun’s neck to the TCP so you can […]

[…] robotic welding supervisor. Benjamin had previously worked for an OEM supplier of robotic welding equipment and was familiar with Tregaskiss products. Jim Benjamin, K-zell Metals, shows the neck for the company’s TOUGH GUN I.C.E. robotic MIG gun. The external water lines circulate coolant to the front-end consumables, helping them run cooler and last longer. […]

[…] lower actual costs for consumables by extending consumable life, it can also prevent weld defects that require costly and time-consuming rework. Tip No. 2: Select the right neck Choose the most appropriate neck for a MIG welding application in order to increase comfort and control, and save money. Rotatable necks, for example, can be […]

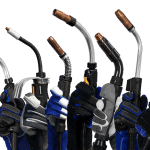

[…] upfront what their long-term applications will be. Will they continue to weld parts that are straight or circular for the foreseeable future? Avoiding pitfalls in the process Necks are typically available in the marketplace in varying lengths, from approximately 4 to 12 inches, and with either straight neck or 22-, 45- and 60-degree bends. […]

PRODUCT UPDATE — TOUGH GUN Neck Checking Fixtures June 24, 2009 Tregaskiss has implemented a series of changes to the TOUGH GUN® robotic neck checking fixtures product line. Below is the new simplified offering of robotic neck checking fixtures: Product Type Part Number Replaces Quick-Change Robotic Air-Cooled Necks G-405CA N/A TOUGH GUN I.C.E.® Robotic Necks […]

[…] of the gun and can adversely affect the life of the front-end consumables. A water-cooled gun can help here. Some water-cooled robotic MIG guns have smaller diameter necks than air-cooled model due to optimized cooling capacity that requires less copper in the neck. As a result, they can reach into tighter spaces, through complex […]

[…] usually up to 1/16-inch diameter. Companies may prefer to mount the wire cutter on a nozzle station or locate it remotely, according to their needs.?? How do neck inspection fixtures work? This peripheral verifies that the robotic MIG gun’s neck is set to the intended tool center point (TCP), allowing it to be readjusted […]

Effective immediately, to simplify the ordering process on Bernard® Clean-Air® fume exhaust MIG guns, we have replaced the two parts needed to complete the complete the body assembly and vacuum tube assembly into one fume extraction neck assembly part number as shown in the […]

[…] to Zammit and Maintenance Supervisor John Dahl, the maintenance on their Q-Gun MIG guns is much simpler than with the competitive guns they used previously. Changing the neck or liner on those guns required an Allen wrench to remove setscrews on the front and backend of the MIG guns, a process that Dahl says […]