PRODUCT CHANGE — Changes to Crimping on Select Nozzles

August 4, 2020

Effective immediately, you may notice a slight change to the crimp area of some Tregaskiss® nozzles. Within our manufacturing process, we have begun to transition from six-jaw to eight-jaw crimpers. Rest assured that the durability and performance of Tregaskiss nozzles will remain the same.

The only difference you will notice is a slight change limited to the crimp area of the nozzle. The difference is shown below:

Timeline for Transitioning to Eight-Jaw Crimpers

(Actual ship dates will be dependent upon existing inventory levels at time of assembly transition)

- July 2020: This transition has already begun on part number 401-6-62, with additional part numbers to follow

- August 2020: All heavy duty (HD) Tregaskiss nozzles will transition to the new style crimp and will be completed by August 31

- September 2020: All standard duty (SD) Tregaskiss nozzles will transition to the new style crimp and will be completed by September 30

For complete product information:

AccuLock™ R Consumables

TOUGH LOCK® Consumables

NEW PRODUCT – Tregaskiss Nozzles for AccuLock R Consumables

NEW PRODUCT —

Tregaskiss Nozzles for AccuLock R Consumables

April 3, 2020

Tregaskiss is proud to announce the addition of two new nozzles to the AccuLock™ R consumables offering. Only slightly larger than 1/2″ bore nozzles, these 5/8″ bore nozzles offer almost the same weld access while still providing the clearance needed for reliable gas flow and reaming to the gas holes.

Part Numbers

- 401-30-62 – 5/8″ bore, 1/8″ stick out, brass, slip-on, 0.938″ O.D.

- 401-30-62T – 5/8″ bore, 1/8″ stick out, brass, thread-on, 0.938″ O.D.

These new nozzles are also now configurable on TOUGH GUN® TA3 and CA3 robotic air-cooled MIG guns. Learn more about AccuLock R consumables, or configure your robotic MIG gun online.

February 14, 2020 Tregaskiss® and Bernard® branded nozzles are currently packaged in a variety of bag sizes and styles. We will begin standardizing on a single size and style bag for all Tregaskiss and Bernard nozzles over the coming months as a running change that takes place as existing inventory is depleted. 5″ x 8″ (white) 8″ x 10″ (white) 6″ x 8″ (clear) 8″ x 10″ (white) (subject to change depending on volume changes)

October 23, 2019 Tregaskiss is pleased to announce the launch of new AccuLock™ R consumables, a system designed to maximize throughput and efficiency with minimal risk and effort. AccuLock contact tips last longer and are virtually impossible to cross-thread. The long contact tip tail concentrically aligns the tip within the diffuser prior to thread engagement, and this coupled with the tip’s coarse thread ensures quick, accurate replacement without cross-threading. An upgrade to AccuLock HDP contact tips can extend life by 10x or more in pulse welding applications. You can easily switch from TOUGH LOCK® and other consumables to AccuLock R consumables with no impact to tool center point (TCP), making this upgrade low effort, low risk, and high payoff. Plus, Tregaskiss AccuLock R consumables and Bernard® AccuLock S consumables share a common contact tip, so you can benefit from the reduced costs and simplified inventory of a common consumable platform™ if you have a combination of robotic and semi-automatic MIG guns in your facility. Reduce troubleshooting, downtime and rework with these new consumables. Learn more about Tregaskiss® AccuLock™ R consumables.

August 20, 2019 Effective immediately, a new, enhanced AccuLock™ S power pin is now available for Miller® equipment. This new power pin is designed specifically for use with the new Bernard® AccuLock S consumable system to optimize performance. Load and Lock for Better Productivity Learn more about AccuLock S consumables.

August 8, 2019 Tregaskiss is proud to announce that we have launched the following new conversion diffusers that receive TOUGH LOCK® contact tips, including HDP: Fronius® TPS 400i Lincoln® Magnum Pro® (Slip-On) Lincoln Magnum Pro (Thread-On) Learn more about TOUGH LOCK consumables.

June 18, 2019 To continue delivering sustainable value to our customers, we regularly assess our product offering to ensure focus on customer needs and opportunities to innovate our product portfolio. Accordingly, this is a notification that we are discontinuing Tregaskiss® SURESTART™ contact tips, due to low demand. Effective immediately: All SURESTART contact tips have been discontinued and no longer available for sale. Visit the TOUGH LOCK consumables page for more information.

January 25, 2019 To continue delivering sustainable value to our customers, we regularly assess our product offering to ensure focus on customer needs and opportunities to innovate our product portfolio. Accordingly, due to low demand, select Tregaskiss® nozzles will be discontinued. Effective March 1, 2019, all nozzles listed in the chart below will be discontinued as inventory depletes, and effective March 30, 2019, these nozzles will no longer be available for sale. Click here to download the above list in PDF format.

November 1, 2018 Bernard is proud to introduce new AccuLock™ S consumables, a system designed to address liner trim length errors and erratic wire feeding. Important Note: Most components of the AccuLock S consumables family are currently available. The complete offering will be coming soon. The AccuLock S liner is locked and concentrically aligned to both the contact tip and the power pin without the use of fasteners, which provides a flawless wire-feed path that guarantees smooth, uninterrupted delivery of the wire to the weld puddle. Plus, the liner replacement process has been error-proofed so you can trim your liner accurately and easily every time, with no measuring. The AccuLock S consumables system requires all AccuLock components: contact tip, diffuser, nozzle, liner, neck insulator, power pin and power pin cap.

November 1, 2018 Customers may notice that some Bernard® parts and consumables are arriving in different bags. We transitioned to a newly designed Bernard branded white bag design. In addition to changing the artwork layout and color of the bags, the overall usability has also been improved. These new white bags offer a clear window on the printed side of the bag to make visual product identification easier. To increase the hanging capacity of the bags, we’ve added a second hanging hole on our larger bags and a new double-sealed header on all bag sizes. The sombrero shaped hanging holes provide compatibility with a wider variety of hook sizes and shapes.

November 1, 2018 Customers may notice that some Tregaskiss® parts and consumables are arriving in different bags. We transitioned from a black bag design to a white bag design. This new white bag design has a clear window on the back side of the bag to help make visual product identification easier, and the durability and hanging holes remain the same as our previous black bag packaging.

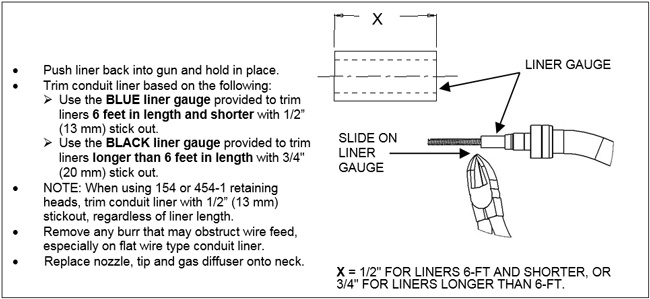

February 3, 2017 Tregaskiss now recommends trimming all rear-loading conventional and front-loading QUICK LOAD® liners that are 6-feet in length and shorter with a 1/2-inch stick out. This new trim length provides performance improvements for the liner and cable, and for wire feeding overall. It also helps to reduce some strain on both the liner and the cable while still maintaining a proper liner seat in both the retaining head and the power pin. Effective late February, all bagged 6-foot Tregaskiss conventional and QUICK LOAD liners will include a new 1/2-inch blue liner gauge along with a technical insert outlining these updated trimming instructions. The outside of each bag will also be marked with a sticker indicating a change to liner trim length.

January 16, 2015 Tregaskiss has improved the crimp on our heavy duty (HD) nozzle offering. The profile on the crimping dies that form the ring crimp has been narrowed from a pad length of 0.450″ to a pad length of 0.390″ (see image below). This change significantly improves the quality of the crimp since it allows for enhanced integrity of the nozzle insulator. Click here to download the TOUGH LOCK® consumables spec sheet in PDF format for more detailed nozzle information.

Liners are still available in lengths of up to 25 feet (7.6 m) for various wire sizes. Part numbers will remain the same as released on June 2, 2014. Please see the chart below for part numbers and wire sizes: 0.023″- 0.030″ Yellow L1A-15 L1A-25 0.030″- 0.035″ Green L2A-15 L2A-25 0.035″- 0.045″ White L3A-15* L3A-25* 0.045″- 1/16″ Red L4A-15** L4A-25** 5/64″ Blue L6A-15 L6A-25 3/32″ Grey L7A-15 L7A-25 7/64″ – 1/8″ Black L8A-15 L8A-25 *Standard Liner for 0.035″-0.045″ Guns

Launched on June 2, 2014, the new Bernard® conventional liners are compatible with all legacy Q-Gun™, S-Gun™ and T-Gun™ MIG guns and all BTB platform guns, which allows you to simplify and reduce your inventory. The image to the right shows how the previous liner locks were merged in the design of the new Bernard conventional liner to maximize backwards compatibility. Due to this customer-friendly backwards compatibility, the part numbers below supersede previous Bernard conventional liner part numbers. Made of high carbon music wire for smooth wire feed and long life, Bernard conventional liners are available in lengths of up to 25 feet (7.6 m) and are color coded for your convenience to indicate a variety of wire sizes. Please see the chart below for part numbers, wire sizes, and color coding information: *Standard Liner for 0.035″-0.045″ Guns NOTE: Tregaskiss conventional liner numbers will continue to be offered due to their continued use in Tregaskiss robotic MIG guns.

Learn more on the Bernard Quik Tip Series product page.

November 12, 2012 The QUICK LOAD® liner AutoLength™ system from Tregaskiss is designed specifically to minimize downtime, wire feeding and quality issues commonly associated with the liner being cut to an incorrect length. Short liners are a common root cause of poor wire feeding. Further, a short liner does not have a chance of properly seating in the retaining head — often resulting in “bird-nesting” of the welding wire or premature contact tip failure and wear. Wire feeding challenges reduce efficiency of the welding process and cause undesirable (and expensive) downtime. A system upgrade to this new innovative product can help improve welding efficiency and reduce costly downtime. Learn more about the QUICK LOAD liner AutoLength system.

May 22, 2009 This optional insulator for the 601 series water-cooled nozzle is now made of high-temperature Teflon material rather than ceramic. This new design is shorter than the previous ceramic version, but outperforms the previous design since it uses a more durable material. This optional nozzle insulator is available as a separate item: Part #601-5-75-4

May 22, 2009 This thread-on nozzle system features a TOUGH LOCK® retaining head with an external thread and a tapered seat.

May 22, 2009 TOUGH LOCK® extra heavy duty (EHD) contact tips (603-20 series) are ideal for large wire sizes, 7/64″ and 1/8″ for example, that can’t be handled with the TOUGH LOCK heavy duty (HD) contact tip series.

January 29, 2009 This adaptor is designed to allow the use of TOUGH LOCK® consumables on Tweco®-style air-cooled robotic necks without changing the original tool center point (TCP).

January 29, 2009 Newly designed, this Miller® quick-connect block (adaptor) receives a 214-1 Miller power pin and assembles into feeders that are compatible with OTC®, Tweco® #4, and Tweco #5 power pins. Part Number: 417-63

September 19, 2008 Due to popular demand, Tregaskiss now offers a TOUGH LOCK® extended life heavy duty (EXHD) contact tip. These contact tips are available in packs of 100 (part #403-27-116).

June 8, 2009 Tregaskiss is pleased to offer a new power pin connection for Cloos® SZ-style wire feeders. This is a complete connection (similar to our Euro style MIG guns) which can be ordered on Tregaskiss® TOUGH GUN® robotic and automatic MIG guns and Bernard® T-Gun™ semi-automatic MIG guns (formerly Tregaskiss TOUGH GUN semi-automatic MIG guns). Robotic applications will also require an external cord set for the clutch. NOTE: This connection is compatible only with a QUICK LOAD® liner. This product is considered a Special Product and has a 15-day lead time, and is available as a product upgrade from a power pin or Euro (part #678C), or on a NEW Special Gun (SG) from Tregaskiss (various SG numbers).

PACKAGING CHANGE – Changes to Tregaskiss and Bernard Nozzle Bag Packaging

PACKAGING CHANGE –

Changes to Tregaskiss and Bernard Nozzle Bag Packaging

Current Bag Sizes and Styles:

New Bag Size and Style:

Transition Timeline

NEW PRODUCT – AccuLock R Consumables

NEW PRODUCT – AccuLock R Consumables

Series Components:

PRODUCT CHANGE – AccuLock S Power Pins for Miller Equipment

PRODUCT CHANGE –

New AccuLock S Power Pins for Miller Equipment

If your power pin has a large ID, please contact Customer Service to get the new AccuLock S Power Pin.

NEW (Shown Right) AccuLock S Power Pin Design

Torque to 10 ft-lbs / 120 in-lbs (13.5 Nm)Affected Part Numbers

2200137 Has been replaced by 2200206 and 2200207 in the AccuLock S consumables system as noted directly following 2200206 Replaces 2200137 for wire sizes 0.023″ (0.6 mm) – 5/64″ (2.0 mm) 2200207 Replaces 2200137 for wire sizes 3/32″ (2.4 mm) – 1/8″ (3.2 mm)

AccuLock S Consumables

NEW PRODUCT – Conversion Diffusers for TOUGH LOCK Contact Tips

NEW PRODUCT —

Conversion Diffusers for TOUGH LOCK Contact TipsConversion Diffuser

Description

DISCONTINUED PRODUCT – SURESTART Contact Tips

DISCONTINUED PRODUCTS – Tregaskiss SURESTART Contact Tips

Affected Part Number TOUGH LOCK® Direct Replacement 403-22-30 403-20-30-25 403-22-35 403-20-35-25 403-22-1.0 403-20-1.0-25 403-22-45 403-20-45-25 403-22-364 403-20-364-25 403-22-52 403-20-52-25 403-23-30 403-21-30-25

DISCONTINUED PRODUCT – Select Nozzles

DISCONTINUED PRODUCTS –

Select Tregaskiss NozzlesPart Number Description Substitution Notes Reamer Change 401-11-62 Nozzle, TIGHT RADIUS™, 5/8″ bore, 1/8″ recess — TCP change – Please contact Customer Service at 1.855.MIGWELD (644.9353) Yes 401-12-50 Nozzle, TIGHT RADIUS, 1/2″ bore, flush — TCP change – Please contact Customer Service at 1.855.MIGWELD (644.9353) Yes 401-13-62 Nozzle, TIGHT RADIUS, 5/8″ bore, 1/8″ stick out — TCP change – Please contact Customer Service at 1.855-MIGWELD (644.9353) Yes 401-19-62 Nozzle, 5/8″ bore, 1/4″ recess, brass 401-14-62 401-14-62 is 1/8″ recess, copper No 401-21 Nozzle, Flux-Core, 1/4″ recess — Discontinued – No replacement No 401-41-75 Nozzle, 3/4″ bore, 1/8″ recess 401-7-75 or 401-14-62 Move to slip-on 401-7-75 with new 404-32 retaining head (v-block change); or Move to 5/8″ bore (copper) 401-14-62 (no retaining head, but cutter change) Yes

(401-7-75: v-block;

401-14-62: RCT-01)401-43-50 Nozzle, 1/2 bore, 1/4″ recess 401-47-51 401-47-51 is 1/8″ recess, and different profile No 401-44-501 Nozzle, 1/2″ bore, 1/4″ stick out 401-44-50 401-44-50 is bottleneck style, not tapered No 401-45-38 Nozzle, 3/8″ bore, flush, old thread 401-4-38 Must use 404-52 or 404-53 retaining head No

(no 3/8 cutter)401-45-50 Nozzle, 1/2″ bore, 1/8″ recess, old thread 401-47-51 Must use 404-52 or 404-53 retaining head No 401-45-62 Nozzle, 5/8″ bore, 1/8″ recess, old thread 401-43-62 Must use 404-52 or 404-53 retaining head No 401-46-38 Nozzle, 3/8″ bore, 1/8″ recess, old thread 401-42-38 Must use 404-52 or 404-53 retaining head No 401-46-62 Nozzle, 5/8″ bore, 1/4″ recess, old thread 401-43-62 401-46-62 is 1/8″ recess; Must use 404-52 or 404-53 retaining head No 401-47-50 Nozzle, 1/2″ bore, 1/8″ recess, old thread 401-47-51 Must use 404-52 or 404-53 retaining head No 401-52-62 Nozzle, 5/8″ bore, 1/4″ recess 401-14-62 401-14-62 is 1/8″ recess No 401-54-50 Nozzle, TOUGH ACCESS™, 1/8″ recess 401-55-50 401-55-50 is flush No 401-55-62 Nozzle, TOUGH ACCESS, flush 401-54-62 or 401-56-62 401-54-62 is 1/8″ recess; 401-56-62 is 1/8″ stick out No 401-68-62 Nozzle, 5/8″ bore, flush, copper 401-51-62 Copper to brass No 401-92-62 Nozzle, 5/8″ bore, 1/4″ recess, brass 401-91-62 401-91-62 is 1/8″ recess No 401-9-75 Nozzle, 3/4″ bore, 1/2″ recess 401-5-75 401-5-75 is 1/4″ recess No 451-4-38 Nozzle, 3/8″ bore, 3/16″ recess 451-6-50 451-6-50 is 1/2″ bore No 451-45-50 Nozzle, High Access, water-cooled (semi-auto) 451-6-50 451-6-50 is tapered style, not bottleneck No 451-5-75 Nozzle, 3/4″ bore, 1/4″ recess, water-cooled (semi-auto) 451-5-62 451-5-62 is 5/8″ bore No 451-81-62 Nozzle, 5/8″ bore, 1/8″ stick out, water-cooled (semi-auto) 451-61-62 451-61-62 is flush No 451-87-62 Nozzle, 5/8″ bore, 3/16″ stick out, water-cooled (semi-auto) 451-61-62 451-61-62 is flush No

NEW PRODUCT – AccuLock S Consumables

NEW PRODUCT – AccuLock S Consumables

Key features of Bernard AccuLock S Consumables

PACKAGING CHANGE – Changes to Bernard Bag Packaging

PACKAGING CHANGE — Changes to Bernard Bag Packaging

Old Bernard Bags

New Bernard Bags

PACKAGING CHANGE – Changes to Tregaskiss Bag Packaging

PACKAGING CHANGES —

Changes to Tregaskiss Bag PackagingOld Tregaskiss Bags

New Tregaskiss Bags

PRODUCT UPDATE – New Liner Trim Length for Liners 6-Feet Long and Shorter

PRODUCT UPDATE –

New Liner Trim Length for Liners 6-Feet Long and Shorter

NOTE: Liners longer than 6-foot in length should still continue to be trimmed with a 3/4-inch stick out. No change to liner gauges or trim instructions for conventional or QUICK LOAD liners longer than 6-feet is recommended.PRODUCT IMPROVEMENT – Changes to Heavy Duty (HD) Nozzle Crimping

PRODUCT IMPROVEMENT –

Heavy Duty (HD) Nozzle Crimping

Affected Part Numbers

PRODUCT IMPROVEMENT – Bernard Conventional Liners

PRODUCT IMPROVEMENT –

Bernard Conventional Liners

Bernard has implemented a material change to all Bernard conventional liners. All liners were previously produced from high carbon music wire. All liners will now be produced from high carbon music wire with tin zinc plated coating. Wire Size Liner Color 15′ (4.57 m) 25′ (7.62 m)

**Standard Liner for 1/16″ GunsNEW PRODUCT – Bernard Conventional Liners

NEW PRODUCT –

Bernard Conventional LinersCompatible with BTB Semi-Automatic MIG Guns and Legacy Q-Gun, S-Gun, & T-Gun Series MIG Guns

New Bernard Conventional Liners

Wire Size Liner Color 15′ (4.57 m) 25′ (7.62 m) 0.023″-0.030″ Yellow L1A-15 L1A-25 0.030″-0.035″ Green L2A-15 L2A-25 0.035″-0.045″ White L3A-15* L3A-25* 0.045″- 1/16″ Red L3A-15** L4A-25** 5/64″ Blue L6A-15 L6A-25 3/32″ Grey L7A-15 L7A-25 7/64″-1/8″ Black L8A-15 L8A-25

**Standard Liner for 1/16″ GunsBernard and Tregaskiss Conventional Liner to New Bernard Conventional Liner Cross Reference Chart for Bernard Semi-Automatic MIG Guns

Wire Size Bernard Liner Part Number Tregaskiss Liner Part Number New Bernard Conventional Liner Part Number 0.023″-0.030″ 43015 415-23-15 L1A-15 0.030″-0.035″ 43015 415-30-15 L2A-15 0.035″ – 0.045″ 44115 415-35-15 LS3-15 0.035″- 0.045″ 43115 — L3B-15 0.045″ – 1/16″ 44215 415-116-15 L4A-15 0.045″ – 1/16″ 43215 — L4B-15 5/64″ 44315 415-564-15 L6A-15 3/32″ 45415 415-332-15 L7A-15 7/64″ 45615 615-18-15 L8A-15 1/8″ 46715 615-18-15 L8A-15 NEW PRODUCT – Bernard Quik Tip HD Series Consumables

NEW PRODUCT –

Bernard Quik Tip HD Series

Designed for shipbuilding, trailer fabrication and other heavy equipment manufacturing operations.

NEW PRODUCT – QUICK LOAD Liner AutoLength System

NEW PRODUCT —

Tregaskiss QUICK LOAD Liner AutoLength System

NEW PRODUCT – Nozzle Insulator for 600 amp Robotic Water-Cooled MIG Gun

NEW PRODUCT —

Nozzle Insulator for 600 amp

Tregaskiss Robotic Water-Cooled MIG Guns

NEW PRODUCT – Thread-On Nozzle System

NEW PRODUCT —

Tregaskiss Thread-On Nozzle System

to copper threads and prolonging the life of the neck

TOUGH LOCK consumable series

NEW PRODUCT – TOUGH LOCK EHD Contact Tips

NEW PRODUCT —

TOUGH LOCK Extra Heavy Duty Contact Tips

NEW PRODUCT – TOUGH LOCK Adaptor for Tweco-Style Robotic Necks

NEW PRODUCT —

TOUGH LOCK Adaptor for Tweco Style Robotic Necks

Part Numbers and Descriptions

PRODUCT IMPROVEMENT – Miller Quick-Connect Block

PRODUCT IMPROVEMENT —

Miller Quick Connect Block

NEW PRODUCT – TOUGH LOCK EXHD Contact Tips

NEW PRODUCT —

TOUGH LOCK Extended Life Heavy Duty Contact Tips

NEW PRODUCT – Cloos Power Pin

NEW PRODUCT —

Tregaskiss Power Pin Connection for Cloos Wire Feeders

Ordering Information