Tips to Optimize the Robotic Weld Cell

Companies invest in robotic welding systems to improve productivity and gain efficiencies in their operation. But if the weld cell layout is not optimized, it can negatively impact those goals — along with the quality of the completed welds.

Poor cell layout can create a bottleneck in the process or result in parts not being properly welded —problems that cost time and money in the long term.

When considering proper layout for a robotic weld cell — whether it’s a pre-engineered cell or a custom cell —gun and consumable selection, robot reach, parts flow in and out of the cell, and weld sequencing are all important.

Pre-engineered or custom welding cell?

Proper weld cell layout is important for both pre-engineered robotic welding systems or a custom-designed system. Determining which option is right hinges on several factors.

A pre-engineered robotic welding cell is designed for welding specific parts in a certain size range. Pre-engineered cells offer benefits for easy and fast installation and a much lower first cost, but they do have their limitations regarding the type and size of parts that can be welded. Part size is often the key determining factor when choosing between the two systems.

If there isn’t a pre-engineered weld cell available to fit the parts — perhaps there is a reach or weight capacity issue — then a custom robotic weld cell is the better option. Custom cells have a higher initial cost and typically a longer lead time for design and installation, but the upside is they can be customized to meet specific needs.

When installing either type of robotic weld cell, the system integrator should be involved in planning and testing to ensure cell layout is optimized for the application.

Choosing the right gun and nozzle

Having the right gun is a critical factor that can help reduce or eliminate the sources of common problems in the weld cell. Gun choice should not be an afterthought in robotic welding applications. The gun must have proper access and be able to maneuver around fixturing in the weld cell. Different choices in gun types and in consumables can help in achieving this.

Robotic welding systems are available in two styles: through-arm or conventional. Through-arm systems are gaining popularity, and most through-arm robots allow for mounting either type of gun — providing more options and flexibility depending upon the needs of the application.

As the name suggests, the power cable assembly of a through-arm MIG gun runs through the arm of the robot as opposed to over the top of it like in a conventional gun. Because of this design, the through-arm gun style is often more durable, since the power cable is protected. However, because conventional guns can be used on either type of system — a through-arm or a conventional robot — they can sometimes offer greater flexibility, and can be used with more robot makes and models. Consider which type of gun provides the best access to the welds when making the selection.

With conventional robotic welding systems especially, proper cable management is important. Once the hardware is installed and the system is set up — but before full production begins — be sure to do a test run or two through the welding sequence to determine how the gun cable moves and if it gets caught on tooling.

Another choice in selecting a gun is air-cooled versus water-cooled. This essentially comes down to the required duty cycle. The base material thickness, weld length and wire size all help determine the necessary duty cycle. Water-cooled guns are typically used in manufacturing heavy equipment and in the case of long cycle times and large wire diameters.

Once the system type and gun is chosen, it’s all about proper fit and function of the gun. It’s critical to ensure the robot arm can access all the welds — ideally in one position with one neck if possible. If not, different neck sizes, lengths and angles — and even custom necks — as well as different consumables or mounting arms can be used to improve weld access.

The choice of nozzle is another important consideration, since it can greatly hinder or improve access to the weld in a robotic cell. If a standard nozzle is not providing the necessary access, consider making a change. Nozzles are available in varying diameters, lengths and tapers to improve joint access.

While many companies like to choose a nozzle with the smallest outside diameter available, it may be necessary to size the nozzle up to avoid spatter buildup and loss of shielding gas coverage. A nozzle with a 5/8-inch bore or larger is recommended because it allows the most access.

Key considerations for proper layout

Choosing the right gun is tied closely to proper weld cell layout — since different sizes and lengths of guns and nozzles can improve or hinder reach to the welds. However, there are also many other factors involved in proper weld cell layout. Think of weld cell layout as the footprint of the entire process. Some important issues to keep in mind:

- Robot reach: It’s critical to match the size of the part being welded with the reach of the robot. A small robot welding on a very large part won’t work well, and a large robot shouldn’t be welding on a very small part. The robot must have the capability and position to reach all the areas on the part that require welding. If there is a weld on the edge of the reach envelope, for example, it might force a company to sacrifice optimal gun angle or work angle to reach that weld. This can impact weld quality, resulting in potential rework and added costs. It can also lead to premature gun or cable failure, if the robot is constantly trying to access a weld that isn’t accessible in the configuration. Many robotic welding cells mount the robot on a riser for better access to the part. Pay attention to proper riser height to optimize the access of the arm to the welds.

- Size and weight capacity: To ensure proper operation, the size and weight capacity of the positioners in the robotic weld cell must factor in not only the weight of the part, but also the weight of the tooling. Undersizing the positioner or weight capacity of the cell is a common mistake. To address this, design the cell for the heaviest part to be welded. Consider the project scope to ensure the welding system always has the capacity to handle the heaviest part in the operation.

- Material flow: The flow of material in and out of the weld cell, in addition to the sequencing of the welding process, are key in determining the right layout and positioning. Understand the material flow to the robot, how the material will be presented to the robot, and then how that welded component will be removed from the cell and moved to the next step in the operation. The weld sequence should be planned in advance, to ensure the robot can reach all the welds with the gun configuration being used.

- Test it with modeling: Software programs that allow virtual modeling or simulation of the weld cell provide the ability to test the many factors involved in proper robotic weld cell layout — from gun and nozzle choice to material flow. Take the time to simulate the weld cell layout and welding process during development. This helps determine which product and positions are needed — and helps avoid issues that could arise later once the weld cell is installed and running. In modeling, consider the components, gun, positioner, tooling, arm movements and the part itself. All these pieces must fit together and work properly to ensure the desired results. The beauty of offline programming and 3D modeling is that these components and factors can be tested virtually, without wasting materials or consumables. It’s better to prepare and prevent problems — rather than face repairs later.

The right choices enhance productivity and quality

Weld cell layout and the chosen components that fit inside have a significant impact on productivity, efficiency and quality of the finished welds. Weld cell layout that is not optimized can even harm the tooling or consumables, and result in increased time and money spent on maintenance and repair.

Protect the robotic weld cell investment by taking the time at the start of the process to test proper cell layout and equipment — to help ensure the end results and productivity gains being sought.

Video | Tregaskiss QUICK LOAD Liner AutoLength System

Tregaskiss® QUICK LOAD® Liner AutoLength™ System

Changing a conventional liner can cost you in more ways than one. The Tregaskiss QUICK LOAD liner AutoLength system can help you eliminate those costs.

The fabrication and manufacturing industries continue to experience demands for greater productivity, increased efficiencies and higher cost savings — often times with less labor to support the efforts. Every improvement companies can make to achieve these goals is beneficial, from offering more operator training to implementing lean practices. Managing MIG guns and consumables that meet the needs of multiple applications is also an important element in achieving those goals, both from an inventory perspective and as a matter of eliminating unnecessary downtime. There are rarely, if ever, welding operations that require only one type of MIG gun or a single consumable. In fact, it’s not uncommon for many companies to have multiple MIG guns and consumables in use as a routine part of their daily operations, especially within the automotive manufacturing and pressure vessel industries. Automakers, for example, often have handheld and automation weld cells all in the same building. Similarly, welding operators working on different-sized pressure vessels may have a 1,500 gallon tank being welded together with a larger, higher-amperage MIG gun, while welding operators are fabricating a smaller tank nearby with much smaller, lighter-duty MIG gun. Understanding how to pair the best gun and consumable with the job can pay off in workflow and cost savings, and help improve the quality of completed welds. In addition, minimizing the part numbers for MIG guns and consumables can simplify inventory, which ultimately saves time for management and saves storage space. It can save time during the welding process, too. In the shipbuilding industry, for instance, welding operators move around frequently so they do not have the capacity to swap out MIG guns to address multiple applications. Instead, they often standardize on one type of MIG gun and swap out the necks, installed with a jump liner that replaces the front part of the liner system (the rest seats in the power cable). Doing so allows them to keep the same gun for the job, while gaining access to a new joint with the appropriate neck length or configuration. Below are five tips to help streamline welding operations and remain competitive by managing MIG guns and consumables effectively. Using fewer power cable lengths throughout an operation is possible when there is a difference of two or three feet between each application. For example, it may be possible to standardize on a 15-foot cable for weld cells that need this or a slightly shorter length — without causing issues with kinking of poor wire feeding. Doing so minimizes inventory and storage space requirements. It also takes away the guesswork when it comes to replacing this part of the MIG gun, as it eliminates the risk that a welding operator or maintenance employee will install the wrong length power cable on a MIG gun. 2. Choose one type of liner, when possible. There are different styles of liners available for MIG guns, including steel liners, D-wound liners or Teflon® liners. Teflon liners are well-suited for wires that are difficult to feed, including stainless steel or aluminum. Standardizing liner types across multiple weld cells, when possible, can reduce downtime for changeover and costs for inventory. Always make sure the liner is properly installed; otherwise, problems like birdnesting and feeding issues can result. 3. Use the same contact tips, even across semi-automatic and robotic weld cells. Use one type of contact tip across applications whenever possible. For companies that have both robotic and semi-automatic welding operations, common consumables can be especially helpful to streamline processes and inventory — while also reducing costs. It is not uncommon in robotic welding applications for welding operators to change contact tips long before they become worn, as it helps ensure that there is minimal downtime for problems associated with failures. These contact tips, however, still have life in them and can be used on semi-automatic MIG guns to reduce part numbers and count in inventory, and overall costs. It can also reduce confusion as to which contact tips to use across the welding operations. Too many different types of contact tips, for instance, can be confusing and can lead to a welding operator using the wrong parts on the wrong MIG guns. That misstep can bring production to a slowdown or a halt. 4. Adapt the power pin. It is not uncommon for companies to have multiple types and brands of power feeders throughout the welding operation. When possible, standardizing the power pin used in every MIG gun, via an adaptor at the feeder, can help streamline the management of various power pins to match these feeders. If a company also has various types or brands of MIG guns, an adapter can also help with gun standardization. The guns can be ordered with the same power pin and plugged into any wire feeder throughout the facility, again streamlining ordering and inventory, and minimizing costs. 5. Review MIG gun amperage and select one to streamline. In some instances, it may be possible to use the same amperage of MIG gun for multiple applications. For example, if 200 amp and 300 amp guns are both part of the inventory, using 300 amp guns in each cell can make it easier to manage inventory. It can also help prevent the potential for overheating if a smaller gun is accidentally used in place of a larger, higher-amperage one for a higher duty cycle job.

The Consumable Challenge proves a welder can change Bernard Centerfire consumables on a BTB MIG Gun faster than competitor consumables. Watch as we compare the strength of our Bernard BTB semi-automatic air-cooled MIG gun handle to those of our competitors. Watch as we compare the in real-time how long it takes to replace a QUICK LOAD liner VS. conventional rear-loading liner.

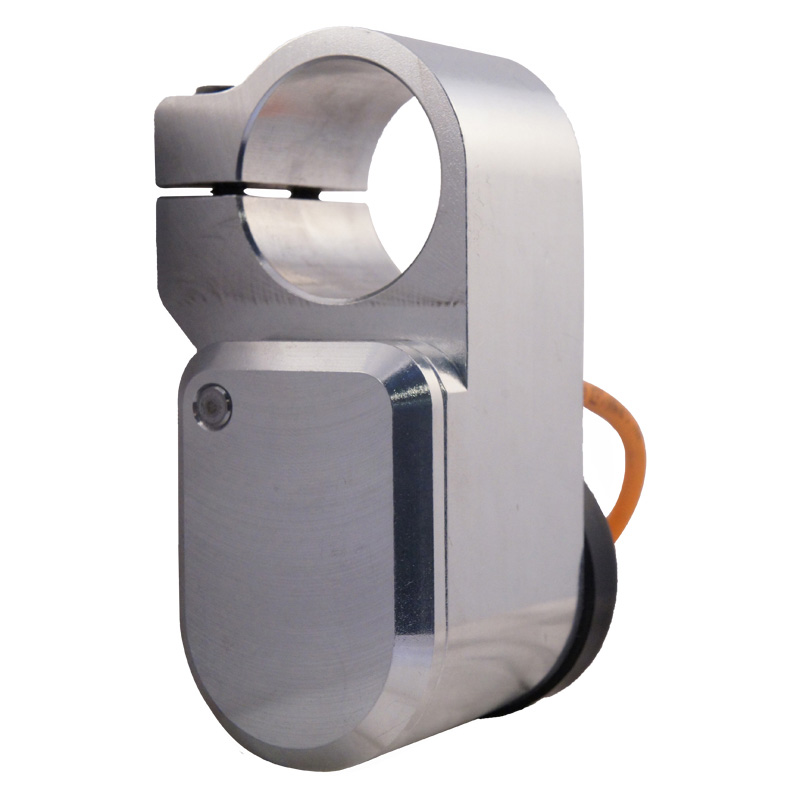

“Graham Corporation serves petrochemical refining markets, some food services. We’re a complete corporation from engineering all the way through manufacturing. I feel that you’re never going to get any rewards without effort and change is part of those rewards. You have to be willing to make those changes and pursue them. When we bought the Pipeworks we found out that we like the Bernard guns that came with it. The ease of operation, durability, the change overs and we just felt it was a good fit for the plant as a whole. We thought it would be to our advantage to have just one consumable for all our guns.” Watch to learn more about what Graham Corporation has to say about Bernard MIG guns and consumables. A robotic MIG welding system contains many components that impact the quality of the parts it welds, its productivity and the overall operational costs. Among those, the robotic MIG gun neck plays a larger role than may first be apparent. Why? The durability of the gun neck — and especially its ability to withstand impacts — is important for maintaining tool center point (TCP). An accurate TCP provides consistency and repeatability from part to part, and is key to the system’s ability to maintain weld positions, especially in assembly line welding where new parts are continually entering the weld cell. A productive and efficient robotic welding system places welds in the same place every time. To achieve this, the MIG gun neck needs to stay in its expected position. A weak neck that easily bends during routine welding can lead to TCP problems over time, as can rough handling of the neck during consumable changeover. Issues with TCP can lead to additional spatter or missed welds, causing rework or scrapped parts. These cost time and money in lost productivity and in wasted parts. An inaccurate TCP can also cause the neck to crash into parts or tooling, potentially leading to damage and unplanned downtime. When selecting a robotic MIG gun neck, look for durable, high quality materials and robust construction. The goal is to have a neck that is strong enough to withstand minor crashes without bending. In addition, be certain there is a solid connection from the neck to the gun, and from the gun to the mounting arm in a conventional system or to the robot itself in a through-arm system. Any play in the system can negatively impact TCP. Neck durability varies, depending on if the application uses an air-cooled or a water-cooled robotic MIG gun. Some applications require water-cooled guns to protect the gun and the neck in high-temperature continuous welding; however, these guns tend to be less durable in a crash than air-cooled gun necks due to the internal soldering of copper and brass lines for the water passages. Air-cooled guns typically feature copper tubes covered with insulation and aluminum, making them stronger and more able to resist an impact. Some manufacturers offer a hybrid air/water-cooled robotic MIG gun, in which the water lines run external to the neck. This type of gun tends to have a stronger neck, like an air-cooled gun, which makes it more tolerant to crashes. However, it is important to ensure the water lines do not hit tooling or parts, which can negatively affect TCP or create leaks. Some key best practices can help protect the neck and provide consistent TCP: All robotic welding systems require a form of collision detection to prevent damage to both the robotic MIG gun and the robot arm in the event of an impact. Some robotic systems incorporate robot collision detection software. Systems that do not have built-in collision detection should always be paired with a clutch — an electronic component that attaches to the gun to protect it and the robot from heavy damage in the event of a collision. Another key peripheral is a neck inspection fixture, which verifies that the gun’s neck is set to the intended TCP and allows the neck to be readjusted after a collision or if it becomes bent during routine welding. If neck adjustment is needed, the welding operator simply adjusts the neck to meet the proper specifications. This prevents costly rework due to missed weld joints and can reduce downtime to reprogram the robot to meet the welding specifications with a bent neck. Having spare necks ready helps gets the system back online quickly. The welding operator need only remove the bent neck in the event of a crash and exchange it with a spare one. The damaged neck can be set aside for inspection later, minimizing interruption to the weld cycle. Choose a high-quality reamer to avoid potential damage to the gun or neck. A reamer, or nozzle cleaning station, removes spatter from the nozzle and clears away the debris that accumulates in the diffuser during welding. A high-quality reamer securely holds the gun in place during the ream cycle, which reduces the risk of bending the neck and compromising TCP. 5. Proper neck and consumable installation and ongoing maintenance are important. Make sure to tighten these components to factory specifications. When changing consumables, remove them with the right tools to avoid bending the gun neck. In many cases, a robotic welding system can provide a competitive edge — offering greater productivity, quality and cost savings. Take care to protect the MIG gun neck, and follow best practices for setup and maintenance, to help ensure the system maintains optimal TCP and the operation experiences minimal downtime.

The liners used in a robotic gas metal arc welding (GMAW) gun play a significant role in the productivity, cost and quality in your automated welding operation, alongside other consumables such as the nozzle, retaining head (or gas diffuser) and contact tip. Liners run the length of the robotic welding gun and power cable — from the contact tip to the power pin — and act as the conduit through which the wire is fed. A poorly installed liner can lead to problems with bird-nesting and excessive debris in the liner, which can both cause wire feeding issues that lead to downtime — the enemy of any robotic welding operation. For this reason, it is imperative to select the right liner for the wire type and diameter being used and to trim it to the proper length.

In robotic MIG welding applications, minimizing downtime is key. It reduces costs and improves efficiencies to help an operation meet its production goals. Gaining the best performance, in part, depends on the equipment being used. Having the right robotic MIG gun and power cable, for example, is critical. There are several factors to consider when determining the right gun style and cable length for the application. Prioritizing these are important, as using the wrong length cable can cause problems ranging from premature cable failure to poor wire feeding. Before selecting the power cable length, first consider whether a conventional gun or a through-arm robotic gun is best-suited for the application. Each style has its advantages and limitations. Through-arm robotic welding systems have become more common, as more equipment manufacturers develop this style compared to conventional robots. Through-arm robotic welding systems, however, allow for the mounting of either a through-arm gun or a conventional one. In some applications, the latter is the better choice. When choosing between the two, consider the available space and weld cell layout, joint access and the type of material being welded. Conventional guns can often access joints better and/or maneuver around tooling or fixturing that a through-arm gun can’t reach. Conventional guns can also be less expensive and faster to install, although they do require proper cable management. They also require more space, so they aren’t typically the best choice in smaller weld cells. Through-arm guns work well in applications where deep access to the part or fixture is necessary. Since they don’t have a mounting arm and take up less space, they also offer advantages in smaller weld cells. The design of the gun —with the power cable assembly running through the arm of the robot —manages excess cable slack, which typically helps them last longer than a conventional power cable. Selecting the proper cable length is critical for both types of guns and numerous factors impact the choice. These include wire feeder, the make and model of the robot, and robot articulation. Having the right cable length helps prevent problems with wire feeding that can lead to downtime and unnecessary labor and/or part costs to address the issue. The wrong cable can further increase costs and downtime due to premature cable failure. When using a conventional gun, a cable that is too short causes tension, which can result in components prematurely breaking down in the cable assembly. It can also cause the clutch or the robot to overload, which will send a collision detection signal that stops the robot — resulting in unnecessary downtime. A cable that is too long is also a problem, because it can get caught on tooling or result in extra weight that bogs down the mounting arm – potentially overloading the clutch. With a through-arm gun, a too-short cable with visible tension also causes problems. Choose a cable that allows some slack for the robot arm to move around. But remember, too much slack can be as problematic as too little slack. When choosing proper cable length for a through-arm gun, it’s important to know the robot make and model, the feeder make and model, and the measurements of the system. If any nonstandard equipment or tooling is mounted to the face of the robot, such as a gripper or a camera, this changes the thickness of the plate and therefore impacts the necessary cable length, requiring it to be longer. It is also important to know where the wire feeder is mounted relative to the robot casting to ensure proper cable length. Much of the same information is needed in choosing the right cable length for a conventional gun: robot make and model, feeder make and model. In addition, consider where the feeder is mounted on the robot or even remotely, as both will affect cable length. For both types of guns, the feeder should be adjusted each time the cable is replaced to manage cable slack properly. Failing to properly adjust the wire feeder can result in a cable that is too tight or long for the given application, causing premature failure and potential damage to the robot or wire feeder. Fixing these issues at the start of the process can help avoid much greater downtime and costs later. Following some best practices can help extend power cable life, reduce downtime and improve productivity. Many of the best practices are related to the programming of the automated welding system. Oftentimes, cables fail because they were set up to fail — the system is asking too much of the cable. Make sure the robot doesn’t articulate too far in either direction, to avoid placing excess stress on the cable, whether it is a conventional or through-arm robotic gun. It’s also important to limit the movements of axis five (bending) and axis six (rotation) to help extend cable life. The joints of the robot get smaller as they move from the base to the wrist. Use the larger joints nearer to the base as much as possible and rely on the smaller joints only when necessary to reach the weldment. In addition, employ a cable management system when using a conventional gun to ensure there isn’t too much slack in the cable. With too much slack, the cable will rub on anything around it and possibly catch on fixturing. When a robot moves at production speed, it can break the cable or fixture. Cable management systems can take the form of a recoil with an adjustment knob and pulley that allows the maintenance personnel or welding operator to adjust the position (length) and tension of the power cable. When using a through-arm gun, choose a rotating power cable connection to reduce the stress on the system. Conventional style unicables typically come with a crimped or solid connection, which limits rotational capabilities and produces torsional stress on the cable. Unlike conventional unicables, a power cable that incorporates a rotating power connection allows for stress-free rotation — and can ensure a longer cable life. Without the right equipment — and proper system programming — downtime can cost significant time and money in robotic welding applications. Take care upfront to choose the right equipment, including the gun and power cable, to save time and money in the long run and keep the operation running smoothly.

When choosing the right MIG gun for a semi-automatic welding application, there are many factors to consider — from the material being welded and the filler metal type to the weld cell layout and expected arc-on time. Customizing a MIG gun for the specific needs of the application, in addition to choosing the proper consumables, can pay off in greater productivity, better comfort and improved quality in the completed welds. There are easy-to-use tools, such as online configurators, available to help users customize a MIG gun. In addition, keep some key factors in mind to help configure a gun that best suits the application needs. Customizing a MIG gun offers numerous benefits compared to using a standard gun out of the box. Customization can maximize efficiency and productivity in a welding operation, and provide greater comfort. These can improve safety and offer longer arc-on time. Essentially, customization ensures that the welding operator has the exact MIG gun for the application. Also, some standard MIG guns may require extra time for assembly right out of the box. Some guns may also require extra components be added before welding can begin. This is not the case with customized MIG guns, which are ready for welding immediately. Customizing a MIG gun is like a pre-emptive strike against issues or challenges that otherwise would add time and money to a welding operation. To choose or customize the right MIG gun, look at several aspects of the welding operation. Like a decision tree, one answer impacts the next choice. First, consider the type and thickness of the base material, since both impact the filler metal selection. Once the material and filler metal are known, these dictate the welding parameters for the application. Understanding the welding parameters is important because the gun selected must meet the amperage and voltage requirements. While it’s important to choose a gun with enough amperage for the job, the larger the gun, the heavier it is, which impacts operator comfort. Next, think about the expected arc-on time and length of the welds. In addition to impacting the necessary amperage of the gun, these factors also play a role in ergonomics. For example, what length of gun is best for the physical space and length of the welds, and what handle style does the operator prefer? These factors come together in building the right gun for the job. The physical space of the welding cell is also an important factor. If there are fixtures or jigs to work around, consider these when configuring the gun and selecting consumables. For example, space limitations in the welding cell can impact cable length — the goal is always to have the shortest cable possible that still meets the needs of the application to avoid unnecessary coiling. The length and bend angle of the gun neck are also factors based on the available workspace and joint access. Remember, it is easier to make design choices like these up front rather than make changes to the gun after it’s purchased. Also consider if the application requires table welding or out-of-position welds. For flat welds at a table, the operator may repeat the same motion over and over. In this case, comfort and repeatability is key and a gun with a shorter cable can likely be used, which helps reduce overall weight. For out-of-position welds, the operator may need to move around a lot to complete the welds. Choosing a longer cable is helpful. Be aware, however, that a cable that is too long can be a tripping hazard for the operator or it can curl and tangle, causing wire feeding issues. There are two main options when choosing a MIG gun cable: steel mono-coil or industrial-grade cables. Industrial-grade cables are more commonly used. Steel mono-coil cables are well-suited for heavy-duty applications in harsh environments. These cables offer more rigidity and support to minimize feeding issues in applications where the wire must travel through a longer cable. Steel mono-coil cables are also used in applications where there is a risk they may get run over by equipment, such as a forklift. Cable lengths can vary greatly — from 10 feet to 25 feet or longer. While a longer cable may be necessary in applications that require the operator to move around, again, try to use the shortest cable possible that will get the job done. Smaller filler metal wire sizes typically call for a shorter cable, since it’s more difficult to push a smaller wire over a greater length. As wire size increases, the cable length can also increase. Deciding the best gun neck and handle choices for the application depends on several factors. These include operator preference and comfort, as well as weld cell space limitations or fixtures. The type of filler metal being used also plays a role. For example, necks with less bend reduce the chances for bird-nesting or other feeding issues with thicker wires and softer wires. Neck options are available with bends ranging from 30 degrees up to 80 degrees for applications where an extreme angle is needed to reach the weld joint. The choice of neck angle is often tied to the style of gun handle being used. Gun handles are available in straight or curved options, and the decision typically comes down to operator preference. For a straight-handled gun, a neck with a 60-degree bend is a frequent choice. Pairing a curved-handled gun with a 45-degree neck is another popular combination. Gun necks are also available in fixed or rotatable options. A rotatable neck makes it easier for the operator to change angles to access the weld joint without having to change out the gun. Straight handles are often paired with fixed necks, while curved handles are often paired with rotatable necks. Other features, such as trigger locking on the handle, which eliminates the need to hold the trigger during welding and increases comfort, can also be added when choosing the gun neck and handle. The bottom line: Choose the option that makes it easiest and most comfortable for the operator to reach the weld joint. Some MIG gun configuration tools also allow users to choose specific styles or types of consumables. Consumables must be able to handle the amperage of the application; some higher amperage applications may require heavy-duty consumables. Inventory management may be another factor — selecting the same consumables across multiple weld cells, when possible, is typically more convenient and cost-effective. The three key consumables to consider are contact tips, nozzles and liners. Consider the challenges or needs of a specific welding application — and the preferences of the welding operator — when selecting the right MIG gun for the job. A customized MIG gun can improve operator comfort, extend the longevity of consumables and offer greater productivity and efficiency in the operation.

An overheated MIG gun can result in downtime, wasted consumables and lower productivity — costing a company more time and money than necessary. Gun overheating can be a symptom of numerous problems, and it can result in catastrophic failure if ignored. Being aware of the common signs and causes of MIG gun overheating can help prevent or quickly remedy the problem. Always know the gun’s amperage and duty cycle rating and the parameters of the welding application. This information tells you how long a specific gun can be used and under what conditions. Gun manufacturers test and rate their products to prevent overheating. A gun’s assigned rating reflects the temperatures above which the handle or cable becomes uncomfortably warm — not the point at which the gun risks damage or failure. In addition, specific duty cycles are tested for each gun, such as 100 percent duty cycle with 100 percent carbon dioxide (CO2) or a 60 percent duty cycle with a mixed shielding gas (CO2/Argon). Most manufacturers list the amperage-to-duty-cycle ratios in product literature, so research a gun’s rating before purchasing. Operating the gun for too long is a main cause of overheating. Know the duty cycle and amperage ratings of the gun, and don’t exceed the duty cycle when possible. When a gun is consistently overheating, you likely need a larger capacity gun for the application. This allows for welding at higher amperages for longer. However, in welding applications that require short bursts of welding — such as thirty 1-inch welds — a larger amperage gun is often not needed and a lighter, more flexible gun may be the right choice. Be aware that shielding gas also plays a role in gun temperature. Mixed gases typically run hotter, while 100 percent CO2 provides more latent cooling to help keep the welding process cooler. Improper stickout or recess of consumables can be another cause of gun overheating. Adjust stickout to make it slightly longer or change the consumables. A longer stickout — combined with a higher wire feed speed and voltage — helps keep front-end consumables out of the weld puddle and running cooler. Also, when the application calls for a higher duty cycle or amperage and the gun has a flush nozzle, pull the tip back 1/8 to 1/4 inch to better protect it from the heat. Using a slightly longer gun neck can also help absorb more heat from the weld puddle, reducing overheating opportunities. A faulty ground or a ground that is too far from the point of the weld can also cause front-end consumables to overheat and wear prematurely. To help combat this problem, position the ground as close to the weld puddle as possible and use as large of a cable as possible to provide a good connection. Knowing the warning signs of gun overheating can help prevent the costly downtime. In applications where the gun is frequently overheating, it may be necessary to switch to heavier-duty consumables or use a larger capacity gun. Implementing some best practices can also help reduce the occurrence of MIG gun overheating — to help you maximize productivity and savings.

In welding, poor wire feeding is a common challenge — one that can be extremely costly for an operation and take a toll on productivity. From the downtime for troubleshooting to faster wear and replacement of consumables, wire feeding issues such as bird-nesting, burnback and liner clogging can have a significant impact on the bottom line. There are many potential causes of poor or erratic wire feeding. It can stem from the style or size of liner being used, the contact tip size, the gun and whether it’s coiled, or other factors. While finding the cause of the problem can be complicated, wire feeding issues often have simple solutions. To best troubleshoot the problem, start by checking for possible issues in the wire feeder and then work toward the front of the gun to the contact tip. There are numerous issues related to the equipment that can cause erratic wire feeding. If the drive rolls don’t move when the gun trigger is pulled, this could be a feeder relay malfunction or a broken relay. Consult the feeder manufacturer in this case. No response when pulling the gun trigger could also stem from a broken control lead. Control leads can be easily tested with a multimeter to see if a new cable is needed. In applications where an adapter is used to connect the gun to the feeder, a poor adapter connection could also be the source of wire feeding problems. Check the adapter with a multimeter and replace it if it’s malfunctioning. Multimeters can also be used to check trigger switches, which can cause feeding issues if they are worn, dirty or damaged from the gun being dropped. In addition, an improper guide tube installation or an improper wire guide diameter can also cause wire feeding issues. The guide tube is used between the power pin and the drive rolls — typically when there is an adapter being used on the feeder — as a way to keep the wire feeding properly from the drive rolls into the gun. Be sure to use the proper size of guide tube, adjust the guides as close to the drive rolls as possible and eliminate any gaps in the wire path to avoid feeding issues. Wire guides are used between the two sets of drive rolls inside the feeder, guiding the wire from one drive roll to the next. These must be properly sized for the wire to avoid problems with wire feeding. The use of incorrect drive rolls can be another common source of erratic or poor wire feeding. When it comes to selecting the right drive rolls, there are several best practices to keep in mind for successful wire feeding. Drive roll size: Drive roll size should match wire size — a .035-inch wire needs to be paired with .035-inch drive rolls. Drive roll style: Choosing the right drive roll style depends on the type of wire being used. The types of drive rolls – V-knurled, U-knurled, V-groove and U-groove – offer pros and cons depending on the wire type. A solid wire is typically used with smooth drive rolls, for example, while a U-shaped drive roll in smooth or knurled tends to work better for flux-cored and metal-cored wires. For context, the groove term refers to the geometry of the shape in the drive roll while the knurled term references the finish inside the groove. Drive roll tension: Setting the proper drive roll tension is important to ensure pressure on the wire is sufficient to push it through without changing its shape or fracturing it, leading to poor wire feeding. Worn drive rolls: Inspect drive rolls every time a new spool of wire is put on, and replace them as needed. An additional note on drive roll styles: take care when setting the tension on knurled drive rolls with cored wires. While the teeth of the drive rolls can help push the wire through, setting the tension too high can result in the teeth fracturing the thin column of the wire, causing bird-nesting in the feeder. When using knurled drive rolls with solid wires, which is sometimes acceptable, proper tension adjustment is critical. There should be enough tension to push the wire through the cable, but too much tension will cause the knurled teeth to dig into the wire and create shavings that can clog the liner. In applications where the welding operator is having trouble feeding cored wire, it can be helpful to use a U-shaped smooth drive roll on top with a U-shaped or V-shaped knurled drive roll on the bottom. The teeth on the bottom drive roll can help push the wire through, while the smooth drive roll on top helps protect the wire shape. Liner issues are among the most frequent causes of wire feeding problems. Here are some things to check: Liner length: A liner that is cut to an incorrect length can cause wire feeding issues, wire chatter, an erratic arc and/or burnbacks. Using a liner gauge can help when trimming the liner. There are also consumables that lock the liner in place (after loading it through the gun’s neck) at the front and back of the gun while concentrically aligning it to the contact tip and power pin. The liner is then trimmed flush with the power pin at the back of the gun. There is no need to measure. This type of system provides a flawless wire-feeding path. Liner size: Using the wrong size liner for the wire can also cause feeding issues. It’s recommended to use a liner that is slightly larger than the diameter of the wire to provide more room for the wire to feed through the liner. Because welding wire is coiled, it tends to corkscrew its way through the liner as it unspools. If the liner isn’t large enough, it takes more force to push the wire through. This can result in the wire breaking inside the gun or bird-nesting at the feeder. Liner style: Liners are available in plated or non-plated styles, and the right choice depends on the geometry of the wire. A plated liner has a smooth finish, while a non-plated liner has a rough finish. It takes less force to feed wire through a smooth, plated liner. Therefore, it’s recommended to use a plated liner with cored wires since they are softer, and using too much force to push them through the liner could cause them to break. Liner buildup: A buildup of debris inside the liner can also lead to poor wire feeding. Debris can be the result of using the wrong type of drive roll, which can cause wire shavings inside the liner, or it can be due to microarcing as the wire corkscrews through the liner. Over time, this microarcing can result in weld deposits inside the liner, which can require more force to push the wire through. Also, dragging the liner across the floor can cause it to pick up dirt and debris. Replace the liner when buildup results in erratic wire feeding. Welding operators can also blow compressed air through the cable to remove dirt and debris each time the liner is changed. Watch for contact tip wear Worn or dirty contact tips can cause wire feeding issues. The hole at the end of the contact tip is large enough for the wire to feed through. With use over time, the contact tip can wear and the hole becomes more oblong in shape. This is called keyholing. In addition, small balls of spatter can sometimes become welded inside the contact tip, causing burnback and poor feeding of the wire. To minimize the opportunity for keyholing, look for a consumable system that concentrically aligns the liner and contact tip, since this connection creates less mechanical wear on the tip’s interior diameter and reduces the risk of keyholing. Less keyholing also means less chance of an erratic arc, excessive spatter or burnback, which helps lengthen the life of the contact tip. These systems also bury the contact tip further in the gas diffuser to protect it from heat damage. Shielding gas cools the contact tip tail as it flows through the gun, further reducing heat and minimizing contact tip wear. Lastly — the gun: Using a gun with a 25-foot cable when one with a 10-foot cable would suffice often results in bunching of the cable. The minute the operator starts coiling the weld cable during welding, wire feeding troubles can result. Choose the proper gun length for the application and keep the cable as straight as possible during welding to help prevent feeding issues. Wire feeding issues can cost time and money in downtime, wear and replacement of consumables and lost productivity. While there are many potential causes to poor wire feeding, many of them have simple solutions. It’s often a matter of methodically working through the checklist, starting at one end and working toward the other, to find the issue and implement a solution.

Through-arm robotic welding systems are becoming increasingly common in the industry, as more equipment manufacturers turn to the development of this style compared to conventional robots. However, there are some applications where it is better to use a conventional robotic gun for these systems, instead of the through-arm gun typically chosen. The good news is that most through-arm robotic welding systems allow for mounting either type of gun — providing more options and flexibility depending upon the needs of the application. And while the choice of gun is sometimes an afterthought, it can significantly impact efficiency, throughput and quality of the finished weld. Choosing the best option for the job up front is key. As the name suggests, the power cable assembly of a through-arm MIG gun runs through the arm of the robot as opposed to over the top of it like in a conventional gun. Because of this design, the through-arm gun style is often more durable, since the power cable is protected. However, because conventional guns can be used on either type of system — a through-arm robotic system or a conventional robot — they can sometimes offer greater flexibility, and can be used with more robot makes and models. There are numerous factors to consider when making the choice between a through-arm gun and a conventional robotic gun for a through-arm robotic welding system: Conventional style guns, which typically offer a longer neck, can provide more flexibility in accessing or reaching certain weldments, whereas through-arm guns may have difficulty reaching around fixturing or tooling in some cases. In applications where a through-arm gun is installed and it doesn’t reach the weldment as needed, a conventional gun can be swapped in for access purposes. In addition, conventional guns are often a good choice in smaller, more modular weld cells that feature short-armed robots. Through-arm guns may not work as well in these situations because there is not as much cable, and therefore the robot doesn’t have as much slack for articulation. Also, because of the way the cable lies in a conventional gun, the bend radiuses of the cable are much larger than in through-arm guns. When welding aluminum, for example, wire feeding is a major contributing factor to poor weld quality, and therefore tight bend radiuses are not recommended. This makes conventional guns a good option when robotic welding aluminum. Uptime and throughput are also critical in robotic welding applications, and maintenance is a key factor that impacts productivity, downtime and costs. Conventional guns often provide easier maintenance because everything is outside of the arm, allowing for parts to be changed or repaired quickly to minimize downtime. Another benefit of conventional guns is they tend to be more cost-effective to purchase and can be installed much faster — saving time and money in setup. Through-arm guns provide their own advantages when matched with a through-arm robotic welding system. In applications that require plunging deeply into a fixture or part, a through-arm gun is often a better choice. Think of a through-arm gun as an extension of the robot arm. This extension allows it to access different areas within the part being welded, depending on the application. In addition, because the cables are more protected on a through-arm gun they tend to last longer overall, which helps reduce replacement costs. The through-arm design naturally protects the power cable and makes it less prone to snagging on fixturing, rubbing against the robot or wearing out from routine torsion. With either a conventional gun or a through-arm gun, there are some common best practices that can contribute to success in robotic MIG welding. First, it is critical that the cable is never under tension when using a through-arm gun, to help prevent premature cable failure. Cable tension is visible on a conventional style gun but not on a through-arm gun since the cable runs through the gun. This makes proper setup especially important with through-arm guns. In addition, it’s best to use a cable management system when using a conventional gun to ensure there isn’t too much slack in the cable. With too much slack, the cable will rub on anything around it and possibly catch on fixturing. When a robot moves at production speed, it can break the cable or fixture. Keep these factors in mind, along with joint access requirements and weld cell layout, when making the gun choice to help improve throughput and productivity.

As companies seek to gain a competitive edge, it’s not surprising that some turn to welding automation. It offers numerous advantages, including greater productivity, improved quality and cost savings compared to a semi-automatic welding operation. However, to gain the most out of the investment it’s important to follow some best practices in the weld cell. These considerations include the careful selection, installation and maintenance of gas metal arc welding (GMAW) guns. As with any type of welding equipment, the goal is to implement the GMAW gun in a manner that optimizes performance, reduces downtime and prevents the accrual of unnecessary costs. It is important to note that the considerations for achieving these benefits may vary depending on whether the robotic welding system uses a through-arm gun or a conventional-style gun. Following are some tips to help. All automated welding systems need some form of collision detection to minimize damage to the robot and the GMAW gun in the event of an impact. Today’s robots typically have built-in collision detection software, making it appropriate to use only a solid gun mount to connect and position the GMAW gun. In some cases, companies like the secondary insurance of using a clutch on robots featuring this software. Doing so, however, can add unnecessarily to the expense of the operation, increase weight on the front end of the robot arm and cause the tool center point (TCP) to be less repeatable. When possible, it is preferable to use a solid mount coupled with collision detection built into the robot, instead of a clutch. Solid mounts offer numerous advantages, especially for systems using a through-arm style gun. A solid mount can aid in achieving a more accurate TCP, providing greater repeatability for more consistent welds. They are also more cost effective and lighter weight, which allows for quicker movement and potentially better productivity. The use of a solid mount, in conjunction with a through-arm robotic GMAW gun, typically opens up the work envelope, so the robot arm can better access the weld joint. For systems with a conventional gun, a solid mount provides little benefit over a clutch in terms of opening up the work envelope or increasing productivity due to the position of the gun in comparison to the faceplate of the robot. Air blast is an optional technology on GMAW guns that can help enhance gun performance. This feature can be factory-installed or retrofitted into a gun. Utilizing air blast when possible helps eliminate debris in the front part of the robotic GMAW gun, reducing opportunities for weld contamination that can lead to poor weld quality, costly rework and downtime. As the name implies, the air blast feature blows compressed air through the front of the gun to remove debris. It can be used with air-cooled robotic guns or water-cooled models. In addition to removing debris that can cause poor weld quality or contamination, air blast can help increase the time between cycles by removing spatter from the front of the gun. The air blast function can also be used to cool down the gun between weld passes, to help operations avoid going over the duty cycle limit when using air-cooled guns. Using simulation software to model the proposed weld cycle before selecting and implementing a robotic GMAW gun can help in achieving the best results with an automated welding system. While the goal with an automated welding system is often to move as quickly and freely as possible, it’s important to remember that it’s typically best to limit excessive robot movements, as it results in longer gun life thanks to reduced equipment stress. Simulation programs can be used to determine proper system setup, including TCP requirements and which nozzle and GMAW gun neck are best suited to get the desired joint access or angle. The reach and access of the gun neck, in particular, is an important factor in system movement and stress. Changing the neck angle from 22 degrees to 45 degrees, for example, can have a significant impact on robot articulation. This is where a simulation program is beneficial, since it can be used to determine the type of neck and the neck angle that are best for the application before making the investment. To gain optimum speed and performance from the gun, it may be as simple as slightly adjusting the height of the risers or tooling to gain better access to the weld and reduce stress on the gun. Among several peripherals that can be added to maximize system performance, a neck inspection fixture is one that can help improve throughput, minimize unnecessary downtime — and help gain the best performance from the robotic GMAW gun. A neck inspection fixture verifies that the gun neck is set to the intended TCP and allows the neck to be readjusted after a collision or if it becomes bent during routine welding. When neck adjustment is needed, the welding operator can simply adjust the neck to meet specifications. This helps prevent costly rework due to missed weld joints and can prevent the downtime it takes to reprogram the robot to meet the necessary welding specifications with a bent neck on the gun. In some cases, the welding operator can simply remove the bent neck and exchange it with a spare neck to get the system back online quickly. The damaged neck can be set aside for inspection later, resulting in less interruption to the weld cycle. Using a neck inspection fixture from day one of an automated welding system helps ensure a consistent TCP. Choosing the right gun and cable for the application — and installing them properly — are key steps toward maximizing performance of the robotic GMAW gun. Consider the weld length, the required amperage and the type and thickness of material being welded when selecting a robotic GMAW gun. Air-cooled guns work well on lower amperage applications and high-volume welds. In heavy equipment manufacturing and similar industries, a water-cooled GMAW gun may be necessary to weld on thicker materials for longer periods of time. Water-cooled guns offer high amperages — usually up to 600 amps — at 100 percent duty cycle. Selecting the appropriate neck, power cable and other gun components can also have an impact on productivity and performance. Choosing the proper neck style and length for the application provides the gun with easy and complete access to the weld joint, which helps reduce weld defects and downtime for rework. Available neck angles typically range from 180 to 45 degrees, with varying lengths to accommodate most robotic welding applications. Necks can also be special ordered for custom TCP requirements when necessary. In addition, power cable style and length can also impact efficiency in robotic welding operations. For through-arm applications, the power cable is often sold in set lengths to match a specific model of robot, so the selection process is easier. For conventional style robots, it’s important to verify the exact length needed. Too long of a cable can easily kink or move during the welding process, while too short of a cable can stretch and shorten cable life. In both cases, it can result in downtime, premature cable failure and increased costs. Also, look for a sturdy power cable that can withstand UV damage from the arc and resist wear. Cables with quick-change features can extend cable life, simplify cable changeover and maximize arc-on time when installed properly. Regularly check all connections on the GMAW gun to ensure they are tight and secure. Doing so helps prevent issues that can lead to weld defect and downtime. Tighten front-end consumables and check that all seals are in good condition. Also be certain the power pin is secure. While checking that welding cable leads are secure, look for signs of wear and replace them as necessary. Remove spatter from the GMAW gun nozzle regularly, ideally applying anti-spatter to protect against buildup. Implement a reamer when possible to minimize damage to the gun and front-end consumables. A reamer (or nozzle cleaning station) removes spatter from the nozzle bore and clears away debris that accumulates around the diffuser during welding, resulting in longer life of the consumables and higher weld quality. The reamer can be programmed to run between welding cycles — either during part loading or transfer — so it does not add to the overall cycle time per part. In addition, track the life span of the GMAW gun liner and replace it prior to failure. Replacement liners should be trimmed to the appropriate length using a liner gauge. Automated welding operations that are larger in size may need to do more frequent preventive maintenance. It’s especially important for companies that complete large weldments on thick materials because they stand to have greater costs and downtime for rework in the event of gun failure. Automated welding systems add speed, accuracy and repeatability to the welding operation. They can help companies increase productivity and reduce costs in a relatively short period. Implementing some best practices can help companies extend the life of the GMAW gun and consumables, and optimize performance and efficiency of an automated welding system — offering them the most out of the investment.

Ensuring a robotic welding cell stays productive and consistently generates a positive return on investment is determined, in large part, by the amount of downtime it incurs. Since robotic welding systems are built for speed, accuracy and repeatability, the cost of arc-off time spent addressing issues is exponentially higher than in a typical welding cell. Having welding operators and robotic weld cell supervisors who can quickly troubleshoot and solve problems makes all the difference when it comes to keeping costs down, generating high-quality results and maintaining optimal efficiency. Here are five common causes of downtime that can occur in a robotic welding operation, along with ways to prevent and address them. If a power cable rubs against the robot, on parts or against tooling, it can prematurely fail and cause unnecessary downtime. In some cases, the cable may even catch on components and wear them out, too. Cables that are too long or too short create excessive strain by either being pulled too tight or flopping around too much and creating strain at the front housing — both of which lead to premature cable failure. These issues are common with conventional style robots, where the power cable connecting to the robotic MIG gun is external to the robot arm. The goal is to set cable length to allow it to exit the front housing with a smooth arc, resulting in minimal strain. Alternately, in the case of a through-arm robotic welding system, downtime often occurs due to improper installation of the gun and/or improper cable length. By adding cable tensioners, which are essentially spring-loaded cable devices that hold the power cable, operators can ensure the cables stay properly supported on a conventional robot. Programming the robot so that it doesn’t accelerate or decelerate too quickly or abruptly can also protect against premature cable failure. In some cases, if the work envelope is quite small, cable rubbing may be unavoidable. Using a protective wrap to shield the cable from rubbing can help. These are available in the marketplace as either a leather or woven nylon cover, or a plastic spiral wrap. When installing a through-arm robotic MIG gun, be sure to position the robot with the wrist and top axis at 180 degrees, parallel to each other. Then install the insulating disc and spacer the same as with a conventional over-the-arm robotic MIG gun. Always be sure the power cable position is correct and has the proper “lie” with the robot’s top axis at 180 degrees, and ensure the power cable has about 1.5 inches of slack when installing it, so it is not too taut. Although consumables may seem like a small part of the robotic welding process, they can have a big impact on how productive and effective an operation is. Nozzles, contact tips, retaining heads (or diffusers) and liners can all fail prematurely or perform poorly for a variety of issues, including spatter or debris buildup, loose connections and improper installation. Issues with the contact tip — especially burnbacks and cross-threading — are also relatively common, and are often caused by a liner being trimmed too short. Choosing durable, easy-to-install consumables is key to minimizing both planned and unplanned downtime in a robotic welding operation. Longer lasting consumables require less frequent changeover. Plus, designs that help less experienced welding operators install consumables correctly result in less troubleshooting. Contact tips with coarse threads and a long tail ensure the tip aligns concentrically in the gas diffuser before the threads engage. These features help minimize the risk of cross-threading. Also, contact tips with greater mass at the front end and that are buried further down in the gas diffuser better withstand heat from the arc to help them last longer. For pulsed welding operations, contact tips with a hardened insert help the tip last 10 times longer than those made of copper or chrome zirconium. That is important since the pulsed waveforms are especially harsh on contact tips and cause them to wear prematurely. Operators should always inspect consumables for signs of spatter or debris buildup during routine breaks in production and, if signs of either are present, replace or clean them. They should also ensure their nozzle cleaning station or reamer is working properly, if one is present, and that it is programmed to ream at a rate that is appropriate for that specific application. It may be necessary to increase the frequency of the anti-spatter spray application or reaming throughout the programmed welding cycle. Check that all consumable connections are clean and secure, as loose connections can generate additional heat through increased electrical resistance, shortening consumable life and/or causing them to perform poorly. Consumable designs that are tapered can also help minimize heat buildup and extend consumable life by offering better electrical conductivity. Welding operators should always follow the manufacturer’s instructions for liner trimming and installation, as a liner can cause inconsistent feeding if cut too short. It is a good idea to use a liner gauge to confirm the correct liner length. There are also spring-loaded modules that work in conjunction with a front-loading liner to help minimize issues if the liner is cut to an incorrect length. These are housed in the power pin and apply forward pressure on the liner after it is installed. They typically allow up to 1 inch of forgiveness if the liner is too short. It is also important to replace liners frequently enough, as a clogged liner full of debris and dirt will not feed properly, and may cause premature contact tip failure. Excessive spatter buildup in consumables can be caused by a nozzle cleaning station that isn’t operating properly and can easily cause unnecessary downtime. Issues related to nozzle cleaning stations can be caused by an incorrect position between this peripheral and the robotic MIG gun nozzle; poor anti-spatter compound coverage; or a dull or improperly sized cutter blade. If a nozzle cleaning station doesn’t appear to be working properly, first check that the robotic MIG gun is concentric to the cutting blade on the reamer. Misalignment of the nozzle can lead to partial cleaning and excessive spatter buildup. Also check that the anti-spatter sprayer, if present, is full, correctly positioned and properly coating the nozzle during spraying. The nozzle should be slightly damp on the inside and outside, and covered up to three-quarters of an inch from the bottom of the nozzle. Note that over-spraying anti-spatter compound can cause nozzles to deteriorate prematurely, so it should never be sprayed for more than half a second. Be sure that the cutter blade matches the diameter of the nozzle bore, so that it can effectively clean during the ream cycle without hitting the nozzle or the gas diffuser. It is also important to have a sharp cutter blade and to make sure that the nozzle is at the correct depth within the jaws of the nozzle cleaning station. Finally, adding an air blast feature to a robotic GMAW gun can help support the nozzle cleaning station’s overall effectiveness. An air blast feature blows high-pressure air through the gun’s front end, which helps remove spatter, debris and other contaminants. This feature can help reduce how often a nozzle cleaning station needs to be used and, ultimately, boost productivity. Collisions can occur as the result of tooling that hasn’t been secured properly, an item inadvertently being left in the weld cell or poor part fit-up. Unfortunately, not only can collisions create unwanted downtime, but they can also damage the robot arm, the robotic MIG gun and/or front-end consumables. Many newer robots are equipped with collision detection software that serves the same function as a shock sensor, but some companies still use a shock sensor as a backup safety measure. For robots that don’t have built-in collision software, a shock sensor can act as a safety device to protect the robot arm and gun from damage if the robot crashes. In the event of a collision, the shock sensor sends a signal back to the robot to alert it to shut down. In order to determine that the shock sensor switch is working properly, operators should conduct a continuity check in the open and closed position of the switch using a multimeter or manually trip it by bumping the neck with their hand. If the sensor is working properly, it will send a signal back to the robot indicating there is a problem. Always reset the shock sensor to its home position and recheck the tool center point (TCP) after a collision, and confirm that both the TCP and clutch are correct. If welding operators are using a newer robot with collision detection software, they should make sure it’s set up correctly and that both the TCP and center of mass or balancing point have been programmed according to the gun manufacturer’s specifications. Doing so helps ensure the robot will react properly in the event of a collision. Poor wire feeding in a robotic welding system is usually caused by one of three things: 1) issues with the liner, such as a clogged liner, 2) a wire feeder that isn’t functioning properly or 3) power cable kinking. Regardless of the cause, the result is poor arc stability and weld quality. As previously mentioned, regularly changing the liner and using a robotic MIG gun with an “air blast” feature help eliminate debris in a liner. If an air blast feature is not available, welding operators can also manually blow compressed air through the liner periodically. If it is suspected that the wire feeder’s drive rolls are the culprits of the poor wire feeding, there are two ways to further investigate and assess the situation. One is to visually inspect the drive rolls for signs of wear, and the other is to conduct a “two-finger” test. The latter involves disengaging the drive rolls, grasping the welding wire and pulling it through the gun. The wire should be able to be pulled easily with two fingers. Lastly, look for kinks in the power cable, which can also lead to poor wire feeding, and then straighten or unwind the cable, if necessary. Remember, knowing how to troubleshoot common problems in a robotic welding operation can make the difference between costly downtime and consistently productive, arc-on time. And making the effort to address potential issues up front can actually save time and money in the long run.

Being as comfortable as possible contributes to welding operator safety and productivity — and it’s a factor that can impact the quality of the finished weld. There are numerous issues that play a role in welding operator comfort, including the heat generated by the welding process, the repetitive motions and, at times, cumbersome equipment. These challenges can take a toll, resulting in aches, fatigue and physical and mental stress for welding operators. There are some steps, however, to help reduce the impact of these factors. These include choosing the right equipment for the job, utilizing tools and accessories designed to improve operator comfort, and following some best practices that promote proper operator form. Promoting operator comfort can lessen the chance of injuries associated with repetitive movement, as well as reduce overall fatigue. Choosing a GMAW gun that meets the needs of the application — and in some cases customizing the gun — is a critical way to impact welding operator comfort so he or she can achieve the best results. A gun’s trigger, handle, neck and power cable design all help determine how long a welding operator can comfortably weld without experiencing fatigue or stress. The application’s weld joint geometry also plays a role in welding operator comfort, and it impacts what components to choose for optimal joint access. Here are some issues to consider in GMAW gun selection that can impact comfort, as well as quality and productivity: Gun amperage can have a significant impact on welding operator comfort because, typically, the higher the amperage, the larger — and heavier — the gun. Therefore, a larger amperage gun may not be the best choice if that amperage rating is not necessary to meet the needs of the application. Choosing a smaller amperage gun when possible can help minimize fatigue and stress on the welding operator’s wrists and hands. In selecting the right amperage, consider the application’s duty cycle requirements. Duty cycle refers to the number of minutes in a 10-minute period that a gun can be operated at its full capacity without overheating. For example, a 60 percent duty cycle means six minutes of arc-on time in a 10-minute span. Most applications do not require the welding operator to use the gun constantly at full duty cycle. In many cases, a higher amperage gun is only needed when the power source is being run continuously. Handle options for GMAW guns include straight and curved styles. The right choice typically comes down to the specific process, application requirements and — most often — operator preference. Keep in mind that a smaller handle tends to be easier to hold and maneuver. In addition, the option of a vented handle promotes improved operator comfort, since this style can cool down faster when the gun isn’t in use. While operator comfort and preference are important considerations, handles must also meet the gun and application’s amperage and duty cycle requirements. A straight handle provides flexibility by allowing to mount the trigger on the top or bottom of the handle. Putting it on top is a good choice to improve operator comfort in high-heat applications or for those that require long welds. There are numerous trigger choices that can improve comfort and safety. Look for a trigger that doesn’t require more pull force than necessary to maintain the arc, to minimize stress on the operator. Also, locking triggers are a good option to alleviate stress on the welding operator’s finger caused by grasping, sometimes called “trigger finger.” A locking trigger, as its name implies, can be locked into place. This feature allows the welding operator to create long, continuous welds without having to hold the trigger the entire time. Locking triggers also help distance the welding operator from the heat generated during welding, making them well-suited for high amperage applications. Another part of the gun that plays a role in operator comfort is the neck. Rotatable and flexible necks are available in various lengths and angles, and can be adjusted to meet specific application needs, offering many choices to help reduce operator strain. Joint access, gun amperage and duty cycle required for an application are important considerations when choosing a gun neck. For example, a longer gun neck can improve operator comfort when the application requires a long reach. A flexible neck can do the same when accessing joints in a tight corner. The best choice for pipe welding might be an 80-degree neck, while a 45- or 60-degree neck might be better suited for welding in the flat position. Rotatable necks allow welding operators to rotate the neck as needed, such as in out-of-position or overhead welding. In cases where you need a longer neck, another option is to utilize a neck coupler, which is a tool that combines two gun necks. The flexibility provided by these numerous neck options can result in reduced opportunity for operator fatigue, strain and injury. The power cable adds weight to the gun and can also add clutter to the workspace. Therefore, smaller and shorter cables are recommended, as long as they meet the needs of the application. Not only are shorter and smaller cables typically lighter and more flexible — to ease the fatigue and strain on a welding operator’s hands and wrists — but they also help reduce clutter and tripping hazards in the work area. Different welding guns can offer different “balance,” which refers to the feel and ease of movement experienced when the welding operator holds the gun. For example, a heavier gun that is balanced properly can lessen operator fatigue compared to a heavier gun that is not balanced properly. A gun that is properly balanced will feel natural in the operator’s hands and be easy to maneuver. When a gun is not balanced correctly, it might feel more unwieldy or uncomfortable to use. This can make a difference in operator comfort and productivity. Because welding applications differ for every welding operator, customizable GMAW guns can be a good option to gain greater comfort. Poor welding operator comfort can directly impact productivity and efficiency. Some gun manufacturers offer online resources to help welding operators configure a GMAW gun for the exact specifications of the job. This helps ensure the gun is suited to operator preferences and the needs of the application — for greater comfort and productivity. ttFor example, most welding operators do not make huge, sweeping movements when using a GMAW gun. Instead, they tend to use more minute, delicate maneuvering of the gun. Some configurations allow users to choose an option available for fume extraction guns — for example, a ball and socket swivel design that helps the vacuum hose to move separately from the handle. This improves flexibility and reduces the wrist fatigue for the welding operator. Utilizing proper weld position and form are additional ways that welding operators can maximize comfort on the job. Repetitive strain or prolonged uncomfortable postures can result in operator injury — or even the need for costly and time-consuming rework due to poor quality welds. Whenever possible, place the workpiece flat and move it into the most comfortable position. It’s also important to maintain a clean working environment. In some cases, a fume extraction gun paired with the proper portable fume extraction system can be a viable option to replace wearing a powered air purifying respirator and lessen the amount of equipment the welding operator must wear. To maintain compliance and safety, it’s always a good idea to consult an industrial hygienist to be certain that’s an appropriate step. In addition, operator comfort can be maximized by using stable posture and avoiding awkward body positioning, and by not working in one position for long periods. When welding in a seated position, operators should also have the workpiece slightly below elbow level. When the application requires standing for long periods, use a foot-rest. Having the right equipment, choosing equipment or accessories that are easy to operate and promote operator comfort, and utilizing proper welding technique and form are all important steps toward achieving a comfortable, safe work environment for welding operators. Lightweight welding guns with appropriate handle and neck designs for the job and for the operator can help achieve safe and productive results. The reduction of heat stress, wrist and neck fatigue and repetitive motions can also help decrease overall physical and mental stress for welding operators. To achieve optimal results, consider the numerous options available in tailoring a GMAW gun that is right for the application and operator preference.