Getting the Most Out of Peripherals

Peripherals — equipment that is integrated into the robotic welding process to make it more effective — can significantly boost the return on investment you achieve from your welding robot. And incorporating and operating peripherals successfully doesn’t have to be difficult. To help, it is important to understand how your peripherals are intended to function and employ some best practices for using them.

Clutches

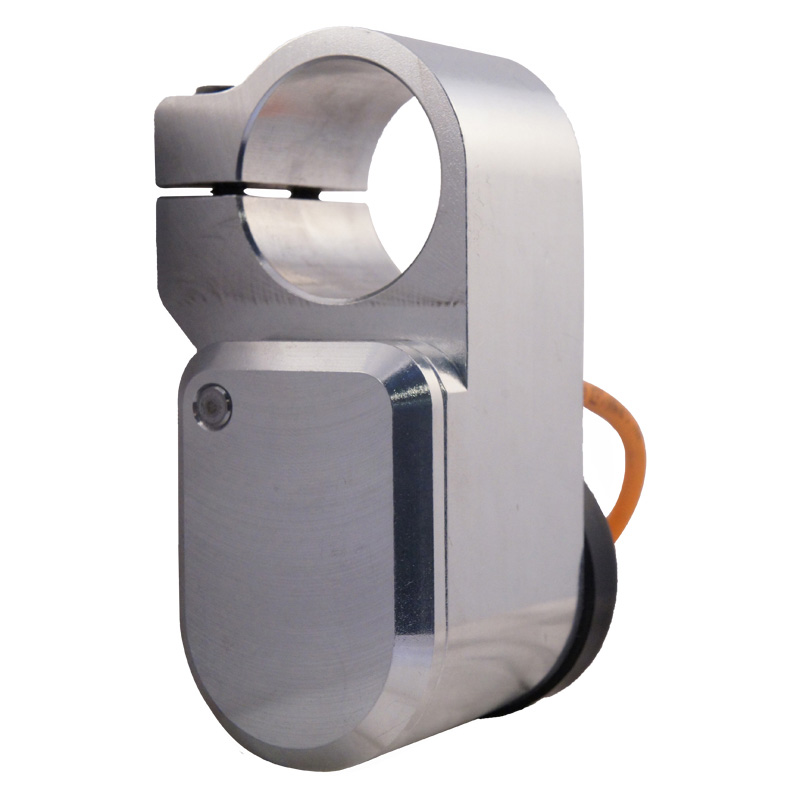

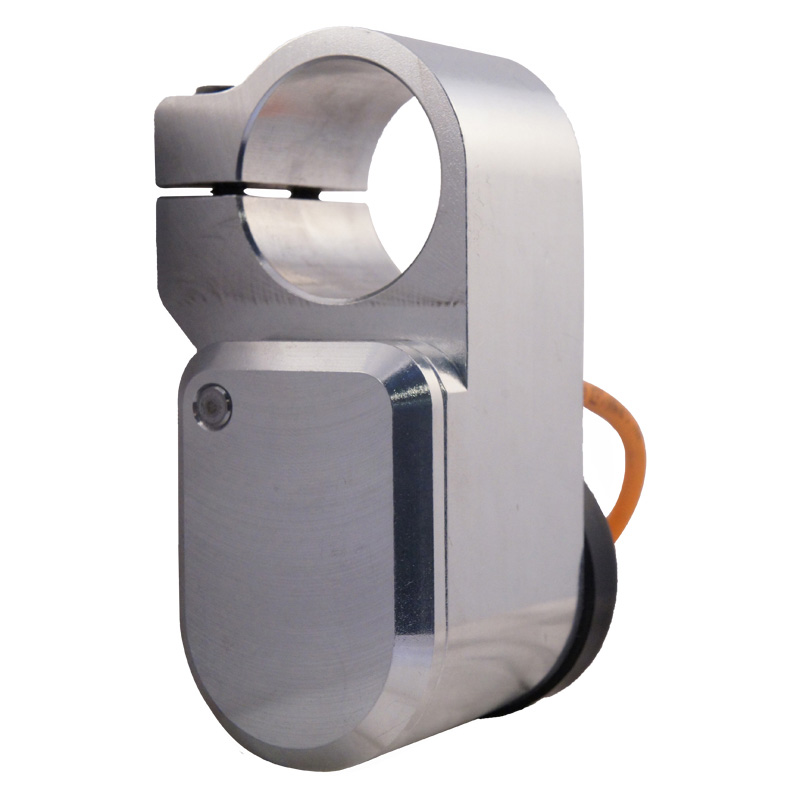

All robotic welding systems require some form of collision detection to prevent damage to both the robotic MIG gun and the robot arm in the event of an impact. Impacts can occur when the robotic MIG gun collides with an incorrectly positioned work piece or out-of-position tooling, or when the gun strikes an item that has inadvertently been left in the welding cell.

Some robotic systems incorporate robot collision detection software. Systems that do not have built-in collision detection, however, should always be paired with a clutch — an electronic component that attaches to the robotic MIG gun to protect it and the robot from heavy damage in the event of a collision. In some cases, you may choose to add a clutch to a system that utilizes collision software as backup protection for the robot.

Always make sure the clutch works with the weight of the load created by the robotic MIG gun and front-end consumables. If the gun is not properly supported and the robot moves rapidly to another spot on the other side of the part, the extra weight can move the clutch out of its optimal position.

If a clutch gets triggered from a collision, reset it by pulling it towards you and letting it snap back into position. After, be sure to check your tool center point (TCP) to ensure the robotic MIG gun is properly aligned for precise welding of the joint. If it is off center, validate that the clutch is in its home position.

Wire cutters

If you have robotic welding applications that require consistent welding wire stick-out — the distance the wire extends from the end of the contact tip — a wire cutter is a recommended peripheral. As the name implies, a wire cutter cuts the welding wire to a specified length or stick-out and also removes any balling at the end of the wire.

Most wire cutters can cut a range of different types of welding wire, including stainless steel, flux-cored and metal-cored, usually up to 1/16-inch diameter. They can often be mounted on a nozzle station or used remotely as needed.

In conjunction with a wire brake, the wire cutter can ensure that the stick-out remains consistent for robots with touch sensing capabilities that help locate the joint.

Neck inspection fixtures

Another key peripheral is a neck inspection fixture, which tests the tolerance of a robotic MIG gun’s neck to the TCP so you can re-adjust it after an impact or after bending due to routine welding.

The advantage of adding a neck inspection fixture to a robotic weld cell is twofold. One, it ensures the neck meets the specifications to which the robotic welding system has been programmed and, once the tolerance has been determined, you can simply adjust the neck accordingly. This can prevent costly rework due to missed weld joints and can also prevent downtime required to reprogram a robot to meet welding specifications with an existing bent neck. Second, a neck inspection fixture can save you time, money and confusion when exchanging necks from one robotic MIG gun to another. Having this ability is especially advantageous if you maintain a large number of welding robots. You can simply remove a bent neck and change it with a spare that has already been inspected and adjusted, and put the robot back in service immediately.

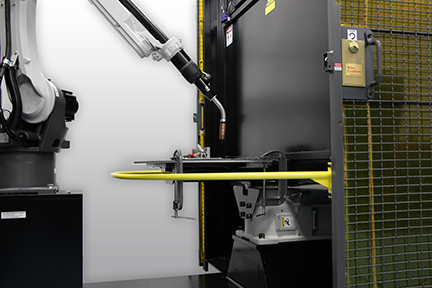

Nozzle cleaning stations and sprayers

One of the most important peripherals you should consider for your robotic welding system is a nozzle cleaning station or reamer. A nozzle cleaning station removes spatter from the robotic MIG gun nozzle and clears away the debris that accumulates in the diffuser during the welding process. This helps lengthen the life of the robotic gun consumables, as well as the gun itself. A clean nozzle also reduces problems that could lead to rework and helps the robot create better quality welds.

During installation, be sure your reamer is on a sturdy base or otherwise securely fastened and not moving around during the reaming cycle. Ideally, the nozzle cleaning station should be placed in close proximity to the welding robot so it is easily accessible when cleaning is necessary. You should program the reaming process to run in between cycles — either during part loading or tooling transfer — so it does not add to the overall cycle time per part.

Always keep the covers on your reamer. The electronics within a reamer can be easily ruined by moisture from the atmosphere. Also, remember to use clean, filtered and lubricated air in your reamer. If “dirty” air goes into the reamer, it will clog up the valves. If you don’t have a lubricator installed on the reamer, use an alternative method to lubricate the air that goes through the motor.

It is important that your reamer matches the diameter of the nozzle and that the blade does not hit the diffuser or nozzle when it goes through a ream cycle. Be sure you are using the right blade for the nozzle you have and that your nozzle is set at the correct depth within the jaws of the reamer.

A reamer can be used by itself or in conjunction with a sprayer that applies an anti-spatter compound to protect the nozzle, diffuser and work piece from spatter. Make sure the nozzle is the correct height away from the spray block and that the duration of the spray is about a half a second. Too much anti-spatter compound can ruin the insulator on your nozzle, and can lead to unnecessary costs for replacement. The compound may also build up on the nozzle, the robot and the parts being welded, resulting in additional cleanup.

Frequently check that the sprayer and sprayer head is free of debris; if spatter gets inside the sprayer head, it will cause the spray plume to be distorted, which will create inconsistent coverage.

If you are using a multi-feed anti-spatter system, be sure you have a good quality hose, such as a urethane hose, and that it is protected from any spatter that may hit it and create a hole. Also, securely fasten the hose with clamps at every connection to prevent leaks.

You may consider using a spray containment unit to capture excess anti-spatter compound. If so, weekly inspections are recommended; remove any spatter or debris that may have fallen to the bottom. Failing to do so can prevent the unit from draining, which will cause the containment unit to overflow and create a mess.

No peripheral decision

The decision to invest in robotic welding equipment is significant. It requires time, knowledge and a trusted relationship with a robotic welding equipment manufacturer to find the right system. The same holds true for peripherals.

Although these devices do add to the initial cost of automating, they can lead to measurable cost savings and profits in the long run. But remember, the goal in robotic welding is repeatability and increased productivity, and any additional equipment that can help achieve these results may be worth your investment.

Implementing and operating a robotic welding system requires attention to detail to gain high productivity and consistent quality. It’s equally important to do whatever you can to protect your investment for the long term — from the robot to the MIG gun and more. In some cases, robotic peripherals are an additional means to help and can provide added safety, in the case of a clutch. As a safety device for your robotic MIG gun, a clutch attaches to the robotic MIG gun and protects it — and the robot arm — from damage. If the robot crashes, the clutch will send a signal back to the robot that alerts it to shut down. Not only does this help prevent further damage to the robotic arm, but it also protects your gun and your front-end consumables. While many newer robots are equipped with collision detection software that serves the same function as a clutch, older robots, which are still very commonly used, are not. Regardless of whether you’re operating a new or older robot, everyone knows your robotic welding system is only as good as the uptime it offers. It’s essential to keep as much arc-on time as possible. When selecting a clutch, you need to choose one that can hold whatever load is going to be on it. For example, if the front end of the gun is extremely heavy and requires significant air movement, some clutches may not be able to support it or may require an adjustment to their sensitivity settings. Also, look for obvious size constraints and make sure the clutch fits within your molding application and tooling. When setting up your clutch be sure to check your tool center point (TCP). Putting on a clutch should not significantly change the TCP. If it’s off, be sure to validate that the clutch is in its home position. Also, when replacing a clutch, make sure the TCP is within specifications. Similarly, always reset the clutch to its home position and recheck the tool center point after a crash. If the tool center point is off, look first to make sure no other damage occurred to another component during the crash. It could indicate that the neck bent out of position, for example, and needs to be straightened with a neck checking fixture or replaced. If all components are undamaged and the deflection is still off, you’ll need to trip the clutch again by pulling it back and snapping it back into place. Typically, the only reason a clutch will fail is if its electrical switch inside fails. If that happens, it will no longer send a signal back to the robot, which will shut down the entire system. In order to ensure the switch is working properly, you can either conduct a continuity check in the open and closed position of the switch using a multimeter or manually trip it by bumping the neck with your hand. If the clutch is working properly, it will send a signal back to the robot that indicates there is a problem. This type of check can be done as part of your preventative maintenance whenever the robot is set up and in a stopped position. Remember, as with any part of the robotic welding system, knowledge is key. Peripherals like clutches serve a distinct purpose in helping make robotic welding successful. Keep in mind some of these tips to help you get the most out of this equipment. Want to improve your MIG welding? By following these seven tips, you can take your MIG welding operation to the next level and ensure you are as safe, efficient and professional as any other shop. Never forget that MIG welding, when done improperly, can be hazardous. Electric shock, fumes and gases, arc rays, hot parts, noise and a host of other possible hazards come along with the territory. The ultraviolet and infrared light rays can also burn your skin — similar to a sunburn but without the subsequent tan — and your eyes. This is why the best MIG welding operator knows how to stay safe. Welding helmets, gloves, close-toed shoes and clothes that fully cover exposed skin are essential. Make sure you wear flame-resistant natural fibers such as denim and leather, and avoid synthetic materials that will melt when struck by spatter, potentially causing burns. Also, avoid wearing pants with cuffs or shirts with pockets, as these can catch sparks and lead to injuries. Keep in mind that heavy-duty MIG welding often produces a lot of heat, sparks and spatter, and requires a lower degree of dexterity than some other forms of welding. Therefore, using thick, stiff leather gloves that provide a higher level of protection is smart. Similarly, choose leather footwear that covers your entire foot and leaves as little room as possible for spatter to fall along your ankle line. High-top leather shoes and work boots often provide the best protection. Finally, always be sure you have adequate ventilation per OSHA recommendations and check material safety data sheets (MSDS) for each metal being welded and filler metal being used. Use a respirator whenever required by the MSDS. Before you get started with MIG welding, conduct online research to see what the best practices are for the specific wire you have or contact a trusted filler metal manufacturer to improve the quality of your welding. Doing so not only tells you what the manufacturer’s recommended parameters are for your diameter wire, but also what the proper wire feed speed, amperage and voltage is, along with the most compatible shielding gas. The manufacturer will even tell you what electrode extension or contact-to-work distance (CTWD) is best suited for the particular wire. Keep in mind that if you get too long of a stickout, your weld will be cold, which will drop your amperage and with it the joint penetration. As a general rule of thumb, since less wire stickout typically results in a more stable arc and better low-voltage penetration, the best wire stickout length is generally the shortest one allowable for the application. Before you start welding, make sure all of your connections are tight — from the front of the MIG gun to the power pin attaching it to the power source. Also be certain there is no spatter buildup on your welding consumables and that you have a ground cable as close to the workspace as possible. Whenever possible, hook the ground cable on the weldment. If that is not possible, hook it to a bench. But remember: The closer it is to the arc, the better. If you have a questionable ground, it can cause the gun to overheat, impacting contact tip life and weld quality. In addition, regularly clean any shavings from the welding wire or debris that collects on your consumable parts and in your liner using clean compressed air. Improper drive roll selection and tension setting can lead to poor wire feeding. Consider the size and type of wire being used and match it to the correct drive roll to improve MIG welding performance. Since flux-cored wire is softer, due to the flux inside and the tubular design, it requires a knurled drive roll that has teeth to grab the wire and to help push it through. However, knurled drive rolls should not be used with solid wire because the teeth will cause shavings to break off the wire, leading to clogs in the liner that create resistance as the wire feeds. In this case, use V-grove or U-groove drive rolls instead. Set the proper drive roll tension by releasing the drive rolls. Then increase the tension while feeding the wire into your gloved hand until the tension is one half-turn past wire slippage. Always keep the gun as straight as possible to avoid kinking in the cable that could lead to poor wire feeding. Contact tips can have a significant impact on improving MIG welding performance since this consumable is responsible for transferring the welding current to the wire as it passes through the bore, creating the arc. The position of the contact tip within the nozzle, referred to as the contact tip recess, is just as important. The correct contact recess position can reduce excessive spatter, porosity, insufficient penetration, and burn-through or warping on thinner materials. While the ideal contact tip recess position varies according to the application, a general rule of thumb is that as the current increases, the recess should also increase. See Figure 1. Always know what gas your wire requires — whether it’s 100 percent CO2 or argon, or a mix of the two. While CO2 is considerably cheaper than argon and good for penetrating welds on steel, it also tends to run cooler, making it usable for thinner materials. Use a 75 percent argon/25 percent CO2 gas mix for even greater penetration and a cleaner weld, since it generates less spatter than straight CO2. Here are some suggestions for shielding gases for common types of wire: Solid Carbon Steel Wire: Solid carbon steel wire must be used with CO2 shielding gas or a 75 percent CO2/25 percent argon mix, which is best used indoors with no wind for auto body, manufacturing and fabrication applications. Aluminum Wire: Argon shielding gas must be used with aluminum wire, which is ideal for stronger welds and easier feeding. Stainless Steel Wire: Stainless steel wire works well with a tri-mix of helium, argon and CO2. For the best control of your weld bead, keep the wire directed at the leading edge of the weld pool. When welding out of position (vertical, horizontal or overhead welding), keep the weld pool small for best weld bead control, and use the smallest wire diameter size you can. A bead that is too tall and skinny indicates a lack of heat into the weld joint or too fast of travel speed. Conversely, if the bead is flat and wide, the weld parameters are too hot or you are welding too slowly. Ideally, the weld should have a slight crown that just touches the metal around it. Keep in mind that a push technique preheats the metal, which means this is best used with thinner metals like aluminum. On the other hand, if you pull solid wire, it flattens the weld out and puts a lot of heat into the metal. Finally, always store and handle your filler metals properly. Keep product in a dry, clean place — moisture can damage wire and lead to costly weld defects, such as hydrogen-induced cracking. Also, always use gloves when handling wires to prevent moisture or dirt from your hands settling on the surface. When not in use, protect spools of wire by covering them on the wire feeder, or better yet, remove the spool and place it in a clean plastic bag, closing it securely. As with any welding process, it takes time and practice to gain the best performance when MIG welding. Following some of these simple steps can help along the way.

Companies invest in robotic welding systems to improve productivity, gain more consistent weld quality and reduce costs. Robotic welding can also set companies apart from the competition by allowing for faster completion and delivery of products. Because of the cost for investing in this equipment, it is important to take steps to protect the system and ensure it is operating at its maximum potential. Keep in mind these best practices and troubleshooting tips to help you avoid downtime and increase throughput in your operation.

Welding automation offers numerous benefits for companies of all sizes — from improved productivity and weld consistency to lower costs for production, labor and materials.When implemented correctly, robotic welding systems also help companies gain a competitive advantage over those that have not made the transition to this technology. More than ever, smaller shops are beginning to make the investment in automation and realizing positive results. There are, however, various considerations to make before adding a robotic welding system to the shop floor. Selecting the right system, assessing the available facility space and training welding operators properly are just a few factors that can help companies gain the best efficiencies and the best payback. Robotic welding systems offer consistency and repeatability that can lead to significant improvements in productivity and finished part quality. That better quality also helps reduce the time and money spent on rework. In addition, these systems can lower production costs by reducing waste and labor requirements. For example, a robot has the ability to lay down the same amount of weld metal each pass with limited supervision, eliminating the issue of over-welding and the associated filler metal waste and cost. Such benefits translate to many applications in both large and small shops. Yet the investment in even one robotic cell in a smaller shop may result in welding automation taking over a higher percentage of the total welding output, for a potentially greater return on investment (ROI). Likewise, while larger companies may have more resources to draw on when adding welding automation, smaller shops can potentially gain greater flexibility while adding automation. In some cases, the owner may frequently be on the shop floor, and employees may wear multiple hats. The outcome is a collaboration that can result in greater employee buy-in on the purchase and an innovative approach to gaining the best efficiencies. Still, a good rule of thumb for any shop considering robotic welding — small ones included — is to fully evaluate the welding operation and parts before making the purchase. When considering welding automation, shops should ask the question “What are our pains?” By identifying goals before starting the process, the company can determine if welding automation is indeed the right solution. Those goals may include improved throughput, increased welding quality or simplified training for welding operators. Once a company identifies the challenges and goals, considering the following can help: Knowing the benefits robotic welding can provide in a specific shop can offer a better understanding of what the ROI expectations are. ROI estimates should consider the labor rate of each shop and how much time welding automation might save, as well as the ratio of machine uptime to downtime for part and fixture changeover. Some shops may have a single part with enough volume to justify a robotic system. In other shops, it may be necessary to combine multiple parts to get the needed volume for ROI purposes. In those cases, grouping by family of parts (like parts of different sizes, for example), can help improve efficiency and save on downtime for fixture changeover. The robotic welding solution needed for a specific company may require a weld cell that is larger than the area available. The need to expand or modify the space to accommodate a welding automation solution adds to the costs and can greatly impact ROI, so it’s an important consideration to keep in mind. While parts don’t need to be perfect, they do need to be repeatable. If there is a gap in a part, it needs to be a repeatable gap so that it can be welded by the system the same way each time. When there is too much variability in the parts, it can lead to more downtime for adjustment or rework. The workflow for robotic welding will likely be quite different than the workflow for semi-automatic orders, which can be changed more easily and produced in smaller batches. A robotic system typically produces three to five times the number of parts in the same amount of time and requires the throughput to be more consistent throughout the entire process. This is one of the most important factors to operate a successful robotic welding operation — especially for first-time users and smaller shops where technicians may not be in-house. Unfortunately, it is also often one of the most overlooked factors. The initial training on a robotic welding system is critical, and many welding manufacturers offer on-site training to help with installation, basic programming and user training. This training can help prevent common issues that keep the system from functioning properly, such as incorrect liner and/or gun installation. It is also important to conduct ongoing training. The features and functions of robotic welding cells can change, so it’s important to remain up to date on them to make the most out of the investment. There are technologies and solutions available that make it easier and more feasible for smaller shops to add welding automation. Pre-wired and pre-assembled robotic weld cells are one such example. In fact, some preconfigured systems can be up and running within a matter of hours. Offline programming can also provide benefits for companies. It allows shops to program parts and design fixtures before the welding actually takes place in the weld cell. This feature offers the ability to remove any mistakes before material is cut for fixtures and can reduce machine downtime for setup. The result is greater uptime and throughput that is consistently high. Several options in robotic MIG gun technology and peripherals can also help increase productivity and reduce downtime for consumable changeover, further increasing the ROI for smaller shops. A robotic cleaning station (or reamer), for example, removes spatter from front-end consumables without the welding operator entering the cell. This spatter removal helps consumables last longer and reduces downtime for maintenance. Front-loading liner systems available for some robotic welding guns are also designed to minimize downtime and reduce issues with wire feeding. Proper installation of the liner is critical to its ability to guide the wire through the power cable and up to the contact tip. Improper liner installation, which includes trimming the liner too short or having a liner that is too long, can lead to a number of issues, including birdnesting, poor wire feeding and debris in the liner. Front-loading liner technology can save significant time in changeover, by allowing operators to easily change the liner at the front of the gun without removing the gun from the robotic system. Some front-loading liners also have a spring-loaded module to accommodate for up to 1 inch of forgiveness for improperly trimmed liners. Increasingly, the positive impact of welding automation is helping smaller shops become more competitive. To gain the benefit of improved quality and productivity, and to reduce costs, companies should always plan out their robot purchase and implementation carefully. A trusted equipment manufacturer is a good resource to help.

Robotic welding systems can provide many companies with increased productivity, improved quality and reduced costs — important and differentiating benefits in the fabrication and manufacturing world. However, simply implementing a robot or two isn’t enough to maximize such benefits. Organizations must understand where they should focus their resources to achieve the most gain. To help remain competitive, companies need continually to look for ways to increase throughput in their overall robotic welding process, while also keeping costs low and quality on par. But given the demographic changes taking place throughout the welding industry — many companies are seeing more turnover in management as longtime supervisors retire and new leaders join the ranks — some managers may not have as much experience with robotic welding systems. Determining how to keep the welding operation functioning in the most efficient, productive and profitable manner may become an intimidating task. This article discusses four key strategies to help welding managers, particularly those new to the job, maximize throughput in robotic welding applications. One of the first steps in improving throughput in robotic welding applications is streamlining in-house processes from beginning to end, to minimize the number of non-value-added activities. Streamlining begins with establishing a clear understanding of the entire production process as it currently functions. Issues to consider include: how long it takes to make a part; how long it takes for a part to go through the entire system; how many machines run at once; how many machines run at full capacity; floor space utilization; how often the part is handled; and proximity of components to the process areas. Gathering this kind of data is helpful in establishing baselines. Once there is an understanding of the entire process, welding managers can start looking for areas to improve. Many of the variable costs in manufacturing come from the process of actually putting products together, so reducing or eliminating non-value-added activities in this part of the process can help to reduce costs. Understanding how much time it takes for a component to move through the entire production process also can reduce the volume of inventory waiting to be processed, which saves costly space. It may also minimize some of the labor used to manage inventory, allowing it to be dedicated elsewhere in the welding operation to help improve the process. Another way to become more efficient in robotic welding processes is to seek out other manufacturers or industry experts who have had success in this area. Find another manufacturer that produces similar products (but is not a competitor) and observe their facilities and production processes. Look for these opportunities with companies known for strength in efficient fabrication or manufacturing, and ones that are gaining success in their robotic welding applications. In short, finding resources that are comparable and appropriate can help with the process of benchmarking areas for improvement. Managers also can capitalize on relationships with industry colleagues and connect with other experts via professional organizations and societies. These networking opportunities can offer good resources for industry knowledge and best practices that can then be applied within the robotic welding process. Managers may also find it useful to seek advice on best practices from the manufacturer or the integrator of the robotic welding system or products (such as robotic MIG guns, consumables or peripherals). These sources often have information to provide about integrating the products with existing equipment or investments that can be made to improve throughput. Another important step for increasing throughput in robotic welding processes is understanding what the key cost drivers are. Understanding the fixed costs and the variable costs in each step of the process enables managers to identify the key cost drivers in the complete production process. Once they have identified and measured the key cost drivers, managers can use that information to decide where to focus attention for improvement efforts to get the biggest impact. This approach can help companies become more efficient and effective operations. Some of the questions to consider when conducting a detailed analysis of cost drivers in manufacturing and fabrication include: how much it costs to produce a part; the time required to perform an activity; how much it costs for equipment maintenance; and how much it costs in lost productivity if equipment is not functioning properly. A detailed analysis of cost drivers also can help a company identify non-value-added activities, such as grinding, cleanup and part movement, and how much time is spent on those activities. This analysis is another step in deciding where improvements can be made to make the most impact on throughput. The purpose of a detailed analysis that looks at time and costs is to clarify and measure cost drivers, with the aim of developing a strategy to improve productivity. Companies can spend a lot of time and effort to measure costs and processes, and develop solutions to improve efficiencies, but may overlook the next key steps: actually following through with the improvement plans and then measuring those accomplishments. Managers may think of improving throughput as an event, when really it’s a process. Hatching good ideas and formulating solutions is important, but implementing those plans and then revisiting them for periodic review is just as important. The bottom line is managers should ask, “Are we actually doing what we said we would do, and is it working?” Implementation is most effective when it happens as a collaborative effort, rather than as a top-down mandate from management. Involve employees from the plant floor up through company management when formulating initiatives. This kind of widespread involvement and buy-in is necessary for continuous improvement and for change to successfully occur. After collaborative implementation, it’s important to follow up with an effective way to easily measure the efforts. An effective measurement strategy helps verify if the implemented processes are paying off. Following a “plan-do-check-act” model of continuous improvement can help manufacturing and fabrication facilities improve throughput in robotic welding applications.

Robotic welding systems provide speed, accuracy and repeatability in many fabrication and manufacturing applications — features that can increase productivity and consistency, and reduce rework. The opportunity for savings due to these quality and efficiency improvements is a primary reason many companies make the investment in automation. There is also an increasing shortage of skilled welders entering the workforce, which makes welding automation an appealing option. However, it takes more than just installing the system to have a profitable automated welding operation. Neglecting other important steps in the process — preventive maintenance, operator training and the use of complementary equipment called peripherals, for example — can result in a robotic welding system that is not performing as well as it should. A less efficient process can lead to more expenses via rework and downtime in the long run, since a robotic welding system is only as strong as its weakest link. This article discusses some common myths about robotic welding systems that can keep a company from fully maximizing the return on investment in this technology, and provides advice to address those misconceptions.

Whether it’s in a small fabrication shop or a large manufacturing facility, investing in a robotic welding system is no minor expense. In many cases, the welding assigned to a robotic cell could also be performed in a semi-automatic or manual welding cell. However, it’s the potential advantages of the system — greater productivity, higher quality, better consistency and more cost savings — that make the purchase of a robotic welding system such an attractive option. Obtaining those results isn’t a matter of chance. At the end of the day, the robotic system needs to be able to produce more parts at an equal or higher quality and accuracy than a human operator. It’s the job of the robotic welding supervisor to make sure that happens. To achieve success in a robotic welding application, there are several key factors a robotic welding supervisor — especially one new to the task — must consider. Specifically, he or she must be able to understand the robotic system thoroughly, establish an effective documentation and maintenance routine, and look for ways to improve performance on an ongoing basis. In many cases, that may also mean enlisting the expertise of resources both inside and outside the company. Understanding the robotic system might seem like an obvious requirement for a robotic welding supervisor. With all of the administrative and operational duties that often accompany the role, however, it can be easy to simply delegate portions of the daily operation of the robotic welding system to shop floor personnel and/or the maintenance staff instead. That tendency, unfortunately, could lead to pitfalls by distancing the robotic welding supervisor from the ins and outs of the robotic welding operation. For example, the robotic welding supervisor doesn’t necessarily need to be able to troubleshoot a circuit board malfunction or rewrite the welding program, but it’s important that this individual has a solid knowledge about these components, so if an issue arises he or she can quickly recognize that there is a problem and alert the appropriate personnel to rectify it. The robotic welding supervisor should also know how the components in a robotic welding system — the robotic GMAW (gas metal arc welding) gun, consumables and cables, to mention a few — relate to each other and the impact they have on weld quality and productivity. Again, having this knowledge makes it easier to identify a potential problem and seek out the best solution. Gaining robotic welding success depends in part on establishing a rigorous documentation, maintenance and control system. When problems arise, as they undoubtedly will, they never occur without a cause. The best way to start the troubleshooting process is to look back to the last thing that was changed in the welding process — or should have been changed, but was not. Keeping an accurate and detailed log of everyone who enters the robotic welding cell is key. There should be documentation of everything personnel cleaned, changed or replaced in the cell, including adding new contact tips or other consumables, changing drive rolls or transferring a new drum of wire into the robotic weld cell. This record can help in identifying the source of a problem and getting the system back up and running with as little downtime as possible. Without such documentation, maintenance personnel could spend hours looking for the source of the issue, when in reality, they may only need a few minutes to rectify the situation. Keeping a log of activities within the robotic welding cell will also assist the supervisor in establishing an effective predictive maintenance schedule, which is the best way to keep unexpected downtime occurrences to a minimum. An activity log can help predict when a gun cable liner will fail, for example, so that maintenance personnel can prevent unplanned downtime and quality problems by changing the liner beforehand. Keeping traffic in and out of the robotic welding cell to a minimum is also important to reducing change within the operation and keeping documentation accurate. The more people coming and going from the cell, the more difficult it becomes to monitor and record activities that could affect the performance of the robot. Getting the robotic system running at peak capacity and providing an acceptable return on investment is just the beginning of establishing an effective robotic welding operation. From there, the robotic welding supervisor should look for ways to optimize and improve the robotic welding operation on a continual basis. A robotic welding cell might be running well enough to meet its daily production demands, but finding ways to improve its performance even more can bring significant advantages to a company. For example, creating greater efficiencies within the system can free up extra capacity that could be used to produce a product from somewhere else in the shop. Also, it’s important not to settle for “good enough” in the robotic welding operations. Accepting suboptimal circumstances — for instance, that a robotic GMAW gun cable is rubbing on the robot arm and must be replaced every two months or that every two hours the operator must adjust welding parameters to accommodate consumable wear — can hinder the efficiencies sought in automation in the first place. A robotic welding supervisor should never consider these types of activities as inherent to the production process, but rather seek out ways to rectify them in the name of continuous improvement. After all, a company that continues investing in robotic welding — compared to one who simply accepts and compensates for problems — stands a greater chance of gainining higher productivity and profitability, not to mention a competitive edge. To achieve the goal of continual improvement and optimization of the robotic welding operation, the supervisor should also know the resources available to him or her, both internally and externally. Internally, everyone from the daily robot operator and the quality technician to the engineering staff and the sales team should be communicating with each other to help improve the existing robotic system. These team members can also play a vital role in helping identify the company’s future robotic welding needs. The daily robot operators — those who load and unload parts and interact with the tooling — often know the specific robot and its idiosyncrasies better than anyone on the shop floor. As a result, they are often in the best position to alert the robotic welding supervisor about potential or existing problems. They may, for instance, notice that certain joint configurations or positions tend to result in excessive spatter, resulting in unnecessary post-weld clean up. By maintaining open communication with these individuals, the robotic welding supervisor can then employ the proper resources to rectify the problem. Quality technicians can be another source of valuable information to help the robotic welding supervisor improve the performance of the operation. Quality technicians might notice that welds in a certain area of a part are regularly oversized. The supervisor can then take this information to engineering, which in turn can look for solutions to revise the weld sequence or identify different system components that could further improve productivity and cost savings for the robotic welding system. Alternatively, an external resource, such as a robotic welding integrator or equipment manufacturer, can often offer insight and expertise gleaned from working with the robotic welding operations at other manufacturers. This knowledge can help companies to not only address issues within the robotic welding system, but it can also put these individuals in a position to offer advice that will make the operation run more efficiently. In this respect, the robotic welding supervisor should take the role of a communicator. He or she will be the one who understands and gathers the information from the resources available, as well as facilitating the conversations necessary to improve and optimize the robotic welding operation. Being responsible for the bottom line success of a robotic welding operation can be a daunting task. It requires a breadth of technical and business experience as well as strong people skills. Plus, as technology continually improves and evolves, the robotic welding supervisor must keep focused on improvement and optimization. They must also maintain open communication with resources both inside and outside of the facility. For those up to the challenge, however, the potential for a robotic welding system to improve quality, productivity and a company’s ultimate success is immeasurable. Worldwide, companies serving the automotive industry have faced a unique set of challenges in the last several years, including changes in material types, a lack of skilled labor and initiatives by OEMs to decrease the weight of vehicles. Still, as the economy continues to rebound, each must find ways to maintain their productivity and profitability — often with fewer employees than before the recent recession. A large part of maintaining that productivity is to ensure high levels of uptime in the robotic welding operations in order to maximize net throughput. It is equally important to find ways to minimize errors and obtain predictive weld data to help anticipate problems in the operation. Conventional issues like spatter, burn-through and poor part fit-up often hinder these attempts, as can the need to manage large amounts of inventory and contend with downtime to service welding equipment. That’s why it’s so important, too, for companies to find equipment that minimizes the total cost of ownership. Unfortunately, there is no single answer to these challenges. There are, however, some considerations that may help reduce automotive suppliers’ pains and assist in other interrelated parts of the process. Best practice meetings: When possible, suppliers in the automotive industry should work with original equipment manufacturers (OEMs) and vendors or welding distributors who can engage regularly in best practice meetings. These meetings can occur by conference call, webinar or in person, and can help determine what practices in the welding operation are working most effectively and what areas need improvement. “Open issues” can be prioritized in order to determine time-phased solutions. These meetings can be especially helpful to companies with multiple locations (even globally), since they help identify opportunities for changes that could positively affect other facilities. They are also an excellent platform for brainstorming error-proofing ideas and serve to open communication among the parties involved in the success of a company’s welding operation. Ultimately, the goal is to spread an assessment of the operation to a broader peer group, extending the company’s core competencies to gain solutions from others’ input. Streamline vendors: Automotive suppliers, particularly those with multiple locations, may want to consider purchasing their robotic gas metal arc welding (GMAW) guns, peripherals, consumables and other welding supplies from a single-source vendor via a welding distributor. Having multiple vendors may appear to provide cost savings on the surface; however, a per-item approach can actually increase the total spend. Instead, by single sourcing a product line, a company is better poised to maximize their purchasing power with one vendor and gain loyalty discounts. The vendor may also be more inclined to aid in new efficiencies and groundbreaking technologies. Plus, a trusted single-source vendor can often help automotive suppliers assess their total weld spend, streamline inventory and reduce costly paperwork. The goal is to work with a vendor who can “own the arc,” providing assistance throughout the whole welding operation by assessing predictive data and offering suggestions for ongoing improvements. “Co-opetition”: If you already work with several welding vendors, co-opetition is your next best option to maintaining an effective welding operation and in some cases can occur as part of best practice meetings. This term refers, in short, to cooperation that occurs between the various equipment manufacturers who are building the end user’s welding solution. Sometimes these companies have competitive product overlap. For example, the manufacturer of the robotic GMAW gun or welding wire may be in direct competition with the company whose power sources are in an automotive supplier’s weld cell. Even so, finding equipment manufacturers who are willing to work together to address problems in the welding operation is key to resolving issues when they arise. A problem with the contact tip, for example, is usually a barometer of other things happening in the process. In short, it is very often a symptom of a problem, as opposed to the root cause. Having partners who are willing to put aside competitive differences for the good of resolving problems like these is important to gaining good welding performance. If this co-opetition is not feasible, companies may want to consider moving to a single-source vendor. Equipment standardization: Recent increases in demand for production have caused some automotive suppliers, especially those in North America, to make capital investments that they previously postponed during the recession. When possible, standardizing on a single brand and style of welding power source, robotic controller, and GMAW gun and consumables during this investment can streamline inventory and maintenance procedures, thereby lowering management costs. It can also help companies avoid long lead times associated with specialty products and improve access to spare parts. For companies in an organic growth mode with new programs and/or greenfield operations, this standardization can help in long-term equipment re-deployment to other facilities, as well as streamline the learning curve among employees, and improve adoption rates and costs. For companies that are in acquisition mode, however, this standardization may not be feasible. Instead, these suppliers should, at a minimum, consider standardizing on a single brand and style of robotic GMAW guns and consumables to minimize inventory. Doing so can also reduce the risk of improper consumable installation, which often leads to unscheduled downtime to rectify. Appropriate welding technology: Many automotive suppliers rely on tandem- welding operations as a means to generate greater productivity. Companies can use this process for line production in the cells housing the majority of the welds. The benefit is that these operations require less floor space and can simultaneously improve throughput. Advancements in single arc pulsed technology have also proven very efficient in providing faster travel speeds and minimizing spatter. This single arc technology, which effectively lowers the average amperage level during welding (by regularly switching the current between high peak amperages and low background amperages), is also quite easy to operate. Given the reduction in workforce in the automotive industry, combined with an overall shortage of skilled labor, this less complex (but highly efficient) technology has already proven beneficial for many automotive suppliers. Companies should work with an appropriate welding distributor or robotic integrator to assess the individual application in order to determine the most appropriate welding technology. Error-proofing: In addition to standardizing equipment when possible, using welding products that minimize the opportunity for human errors is an important part of keeping the welding process flowing. For example, nozzle detection can eliminate the potential of excessive rework or scrap. Avoiding errors in equipment installation is also critical, as missing or incorrectly installed components on the front end of a robotic GMAW gun can cause it to become electrically alive, leading to premature failure and poor welding performance. Preventive maintenance: Even though preventive maintenance or PM may have become a commonplace buzzword in recent years, the fundamentals are still critical to providing good welding performance and reducing unscheduled downtime in the automotive industry. Companies should take care to inspect all connections in the ground cables, feeding assembly, wire feeder, GMAW gun and consumables on a regularly scheduled basis. Replacing worn components during scheduled downtime (at the beginning of a shift, for example) can help prevent problems during production. On some welding robots, “predictive maintenance” technology is available to send alerts when consumables need to be changed. Built-in buffers: As is typical in automotive “just-in-time” applications, suppliers want to reduce work in progress (WIP) — maintaining only strategically determined micro-inventories — and keep parts flowing (Takt time). To continue that workflow but still allow for any instances of stoppage in a robotic welding cell, suppliers may consider building a buffer into production. For example, if a company has a production line of 40 welding robots, breaking that line into fifths (five sections of eight robots), allows them to address any instances of failure while causing a stoppage of only eight robots instead of shutting down production on all 40. That buffer can mean a significant difference in terms of lost production and money. And while no single one of these considerations can ensure the levels of productivity and profitability to which automotive suppliers strive as production demands increase, they can be a step in the right direction. Automotive suppliers should consider working with a trusted welding equipment manufacturer and vendor to discuss a plan for assessing their robotic welding operation and identifying opportunities for improvement.

Consistent productivity, high quality and low costs are all key components in a successful welding operation. Gaining these advantages depends on everything from the equipment and filler metals to the skill of the welding operators and the techniques being used in the process. The shielding gas also plays a critical role. Both the gas metal arc welding (GMAW) process (using solid or metal-cored wires) and the gas-shielded flux-cored arc welding (FCAW) process require the use of an external shielding gas, each type of which offers distinct characteristics. Knowing how to select the appropriate one for the application can go far in helping obtain the desired welding performance and minimizing the downtime for rework caused by poor weld quality. To help, following are some basics of what you should know about shielding gases. The primary purpose of shielding gas is to protect the molten weld pool against elements in the atmosphere, including oxygen, nitrogen and hydrogen. The reaction of these elements with the weld pool can create a host of problems, including (but not limited to) porosity and excessive spatter. Shielding gas also plays an important role in determining weld penetration profiles, helping maintain arc stability and achieving the desired mechanical properties in the finished weld. Shielding gas can also affect the transfer of the filler metal from the arc to the weld joint, which in turns contributes to the efficiency of the welding process and the quality of the weld. Other important factors that shielding gas help determine include the weld bead appearance, and weld toughness and strength. The four most common shielding gases used in the welding process are carbon dioxide, argon, helium and oxygen. Each has specific characteristics and factors such as cost, available labor (i.e., for weld preparation) and the weld properties desired — all considerations when selecting which shielding gas is best for a given welding application. Carbon dioxide (CO2): This gas is the most common of the reactive gases used in the welding process and also the least expensive of the shielding gases. It is also the only one able to be used without the addition of an inert gas. One of the biggest advantages of pure CO2 is that it provides deep weld penetration, which is useful when welding thick material. It does, however, tend to create a less stable arc and more spatter than when it is mixed with other gases, including argon. This additional spatter can lead to downtime for post-weld cleaning. Pure CO2 is also limited to use in short circuit welding processes. Argon: When welding aluminum, magnesium or titanium, it is common to use 100 percent argon as a shielding gas due to its stable arc features. Adding argon to a CO2 shielding gas is also an option for materials like carbon steel. It provides consistent weld quality and appearance and good weld pool control, and can help minimize post-weld cleanup. Argon also produces a narrow penetration profile, making it useful for fillet and butt welds. Typical mixtures include a balance of 75 to 95 percent argon with 25 to 5 percent CO2. An argon/CO2 shielding gas mixture allows the use of a spray transfer process, which lends itself to high productivity rates and visually appealing welds. Helium: Helium is generally used when welding non-ferrous metals. It is also used in a tri-mix formula of argon and CO2 for welding stainless steels. The gas produces a wide, deep penetration profile, making it suitable for welding thick materials, and also creates a hot arc, which helps increase travel speeds and productivity rates. Helium is typically used in ratios of 25 to 75 percent helium with an appropriate balance of argon. Adjusting these ratios changes the weld penetration, bead profile and travel speeds. It’s important to note that helium is more expensive than other gases and requires a higher flow rate than argon (because it is so light). For this reason, it’s imperative that companies calculate the value of the productivity increase against the increased cost of this gas. Oxygen: Oxygen is a reactive gas typically used in ratios of 9 percent or less. The addition of the gas to a mixture with argon helps to improve weld pool fluidity, weld penetration and arc stability, particularly when welding carbon, low alloy and stainless steels. Because the gas causes oxidation of the weld metal, it is not recommended for use with aluminum, magnesium, copper or other exotic metals. To achieve the best results out of a chosen shielding gas, it’s important to select the proper front-end consumables. These consumables — the gas diffuser, contact tip and nozzle — play a critical role in delivering the shielding gas to the weld pool and also protecting it from the atmosphere. Consider these tips to help with the selection. 1. Choose consumables that have a smooth surface to help resist spatter build-up that could block shielding gas flow and lead to issues, such as porosity. 2. Choose an appropriate size nozzle for the application. A nozzle that is too narrow for the application can easily become clogged with spatter, again, hindering its ability to deliver enough shielding gas to the weld pool to protect it. 3. Consider using nozzles with a built-in spatter guard. These designs add a second phase of shielding gas diffusion, resulting in even smoother, more consistent shielding gas flow. 4. Be certain to select quality gas diffusers to ensure smooth and balanced gas flow. Consult with a trusted welding distributor for recommendations. Implementing a robotic welding system isn’t something that happens on a whim — at least not successfully. Converting to this technology can help companies gain greater productivity, improve quality and reduce costs in the welding operation, but the process requires thorough planning to gain those results. Working closely with a robotic integrator is a good step to ensure every aspect of the implementation is carefully orchestrated and that the robotic welding system works properly for the given application — in reality, not just theory. Before adding a robotic welding system, it’s helpful to know some key factors that can maximize the return on investment (ROI) in the technology and also help prevent potential problems. The quality of part produced by a robotic welding system depends on the quality of the part that enters the weld cell. That’s why it’s not uncommon to hear the phrase “garbage in, garbage out” when it comes to robotic welding systems — if the part entering the welding cell is flawed, the subsequent weld will be, too. To protect against poor weld quality, it is critical to have simple, consistent parts that allow the robot to execute the weld in the same location, repeatedly. Having a blueprint or electronic CAD drawing is helpful for confirming that repeatability. Robotic integrators can review the blueprint or they may want to create a software simulation that assesses the suitability of the part for the robotic welding system. After the assessment, they can advise of any adjustments that need to be made prior to implementation. Proper fixturing is also critical to achieving part repeatability, regardless of whether the application is high volume/low variety or low volume/high variety. Parts that meet the exact specifications can easily be welded incorrectly if they are not held in an exact position during the process. Many robot manufacturers offer vision systems to aid in part recognition and to ensure that the weld path can be altered in real time if part fit-up issues exist. These systems usually work very well, but may cost more. Robotic welding systems require a properly trained operator to oversee them. A skilled welding operator or an individual with previous robotic welding management experience is a good candidate for the job. Again, a trusted robotic integrator is an excellent resource to provide the necessary training, which should cover proper programming, troubleshooting and preventive maintenance. As a best practice, companies should also consider ongoing training support to keep the operator’s knowledge of the system up to date. In many cases, robotic OEMs offer online tutorials, troubleshooting information and/or additional on-site training as aftercare support. Many facilities already have fume extraction systems in place for manual welding operations, but converting to a robotic welding system may require additional equipment to help maintain a healthy work environment. With the increased production brought forth by a robotic welding system, there is also an increase in fume generation. Given the stringent regulations and recommendations from OSHA (Occupational Safety and Health Administration) and other safety regulatory bodies, proper equipment is necessary to maintain compliance. For larger facilities with higher production robotic welding applications, a centralized fume extraction system is a good option. These systems involve the installation of ductwork throughout the facility and the placement of fume extraction hoods over the welding cell. Smaller shops with fewer robotic welding cells may want to consider a less expensive portable fume extraction system. Operators can wheel these systems right next to the welding cell and adjust the extendable arm toward the robot to suction the fumes. It is also critical that the proper cage and screens are in place around the robotic welding system to protect employees from the welding arc and moving parts within the cell. Adding weld data monitoring capabilities and/or peripherals into a robotic welding system can help improve weld quality and productivity. Achieving these results, however, requires an additional up-front investment. Weld data monitoring (whether integrated in a power source or via a third party) allows companies to track the parameters of individual welds, determine the cause of weld defects and identify general inefficiencies in order to rectify those problems and optimize the process for peak quality and productivity. This equipment requires the purchase of software and computers, as well as the establishment and maintenance of an Ethernet network throughout the facility. Companies will also need tech-savvy individuals to review the data and make the necessary adjustments to the robotic welding system according to the data provided. Similarly, the addition of peripherals — particularly a nozzle cleaning station (also called a reamer or spatter cleaner) can improve weld quality and productivity. By cleaning spatter from the inside of the welding consumables on the front end of the GMAW welding gun, this peripheral helps extend consumable life, reduces downtime for changeover during production and also reduces the cost for replacing consumables. Nozzle cleaning stations also help minimize the loss of shielding gas coverage (due to spatter build-up) that could lead to poor weld quality and rework. Preventive maintenance of the entire robotic welding system, including the robotic GMAW (gas metal arc welding) gun, consumables and cables is an important step in protecting the investment in this technology. Neglecting maintenance can easily lead to unscheduled downtime, poor quality parts and/or costly repairs. It may even lead to failures that require equipment replacements. Scheduling time to check connections throughout the system, clean fixturing (to prevent debris that may affect part fit-up) and check TCP (tool center point) helps ensure that the robotic welding system continues to operate within its proper parameters. Certain maintenance can occur in between shifts — cleaning off the robot or changing consumables, for example — while other activities like greasing the robot’s joints may occur less frequently and during a longer scheduled stop. Companies need to assess their individual needs and plan the preventive maintenance schedule accordingly. For larger companies, hiring a maintenance crew to take care of preventive maintenance may be desirable. Retrofitting robotic welding systems is a common practice among many companies, particularly those investing in automation for the first time or for smaller shops requiring only one or two weld cells. It’s significantly less expensive to purchase a used robot than a new one. When retrofitting a robot, however, it is absolutely essential that it is capable of communicating with the selected power source if companies are to have the entire robotic welding system function properly. New power sources feature software that may not be immediately compatible with a robot that is older, or in some cases, the robot may need a specific robotic GMAW gun that isn’t readily available at a welding distributor or possibly even discontinued. For this reason, it is critical to contact an experienced robotic integrator who can both recommend and help set up all components in the retrofitted robotic welding system. The investment in this assistance can help ensure the proper functioning of the equipment and the long-term cost savings sought by implementing the system. Not to mention, it can also save a lot of frustration and downtime. Robots rely on the input of the operator to execute a given task. That task, however, doesn’t have to be limited to just welding or to welding the same part every time. Operators can program the robot to weld multiple parts over the course of a single shift, enhancing the versatility of the robotic welding system and positioning the company to produce additional output. Operators can also program robots to move parts so that a particular unit is not sitting idle when it isn’t tasked with welding; there are components that offer gripping capabilities and can be installed in addition to a welding gun. Companies may even have a tool dock that allows the robot to be fitted with a different tool and proceed with its work. Some companies with multiple robots may also benefit from installing a vision system in order to check on the work of the others, ensuring that part fit-up is optimal and that the robot is correctly placing welds. Given that the goal of any robotic welding system is uptime, having the versatility to use a robot for multiple tasks can contribute meaningfully to the other advantages of this technology – increased productivity, improved quality, decreased costs — and may help give companies a real competitive edge.

In the fabrication and manufacturing world, quality and productivity are everything. To remain competitive, companies need to look continually for ways to increase throughput and minimize defects, while also keeping costs low for parts and labor. In many cases, turning to robotic welding is a means to achieve those goals — for both the smaller job shop and larger manufacturing facilities. The decision to implement a robotic weld cell, however, takes a good deal of consideration and planning if the system is to function in the most efficient, productive and profitable manner. And it requires a significant investment. Fortunately, the long-term benefits of a robotic welding operation can be very positive. For companies who have already invested in robotic welding, but are looking to improve or better understand their operations, or for those considering the investment, it is critical to consider some key factors about the technology. Here, we will explore “what you must know about robotic welding” to make the most of the process. Justifying the cost of a robotic weld cell comes down to the ability to gain (and prove) a payback on the investment. Typically, that payback comes in the form of greater productivity and higher-quality welds (which minimize instances of costly and time-consuming rework), but there are other contributing factors to the return on the investment (ROI) in this technology. Robotic welding also offers the advantage of lower energy and labor costs, and in many cases lower material costs due to fewer instances of overwelding. Overwelding is a common and costly occurrence in semi-automatic welding. A weld bead that is 1/8-inch larger than necessary can double filler metal costs, but a robot can reduce those costs by only putting down as much material as necessary. Plus, robotic welding systems use bulk filler metals (600-pound drums, for example) that companies can often purchase at a greater discount. For companies just considering the investment in robotic welding, it is important to consider how to calculate the payback. Assess the current part cycle times and compare those to the potential cycle times of a robot. A trusted robotic welding integrator or OEM can often help with this calculation. During this process, also consider the possibility of reallocating existing labor to other parts of the welding operation, where these individuals can add value to the process. Remember, up to 75 percent of the cost in a semi-automatic welding operation is labor. If there is the opportunity to use that labor elsewhere to increase part production, the payback on the investment in robotic welding will increase. Most companies — particularly smaller ones or those with frequent production changes — seek a payback on the robotic welding investment of no greater than 12 to 15 months. That time frame is entirely possible to achieve with proper up-front planning of the part blueprints, fixturing and general setup of the system. In some cases, companies may be able to justify a longer payback period if they know that their production needs will remain relatively static for longer periods of time. The output from a robotic welding cell is only as good as the parts fed into it. In order to gain the advantages of these systems, it is critical to have accurate, repeatable part designs. Gaps, poor fit-up or poor joint access all prevent a robot from completing its job correctly. The best part designs for a robotic welding application are simple ones that allow the robot to execute the same weld repeatedly. High-volume applications with low-variety parts are especially poised to gain the advantages of robotic welding. Companies should try to avoid part designs that require intricate tooling or clamping to hold it in place, as both can hinder the efficiency of the robot and also add to the up-front cost of the operation. That said, in some cases, companies may still be able to gain a good payback on the investment in tooling for slightly more complex parts, but they will need to weigh out the pros and cons of that cost ahead of time. Companies also need to be certain to assess their overall welding operation for consistent process flow. Bottlenecks upstream can easily slow down the movement of parts into the robotic work cell and the ability of the system to function to its full capacity. A robot that sits idle costs time and money. Some companies may need to reconfigure operations or set up a flexible cell that can manage quick tool and fixture changes in order to minimize bottlenecks in the process flow. It is also important to have adequate labor to supply the robot with parts. Again, companies should consider tapping the knowledge of a robotic welding integrator for advice and assistance to optimize process flow. The robotic MIG gun and consumables on a robot together are responsible for directing the current to the arc to complete the weld, making them integral components in the whole system. To gain the best quality and to avoid expensive downtime for maintenance, repairs or replacement, companies need to select a robotic MIG gun that is suitable for the amperage, duty cycle and cooling capacity needed in the application. Using a robotic MIG gun that offers inadequate cooling or amperage can cause performance issues and lead to premature failure — both factors that increase costs and downtime. Likewise, using a robotic MIG gun that offers higher amperages than necessary raises the total cost of ownership, as typically the cost of a robotic MIG gun increases directly in proportion to its amperage. Companies also need to select their consumables — contact tips, nozzles, retaining heads (diffusers) and liners — carefully and manage them properly in order to gain optimal productivity and lower costs. Look for contact tips with more mass at the front end and that are buried further in the gas diffuser — both features help the tip resist heat from the arc. Consumables with tapered connections mate securely together to provide good electrical conductivity, which also reduces heat buildup and helps the consumables last longer. Contact tips with long tails and coarse threads are also a good option to simplify installation — they virtually eliminate cross-threading because the tail concentrically aligns the contact tip within the diffuser before the threads engage. This easy-to-install design works well for operations with less experienced welding operators who may not be as familiar with consumable changeovers. It also helps reduce unplanned downtime for troubleshooting associated with cross-threading. As with robotic MIG guns, carefully matching the type of consumables to the application can keep companies from having to address premature failures and/or accrue costly downtime (not to mention, lapses in production). It can also keep them from overpaying for consumables that may be too much for the application. Companies should also consider the mode of welding when selecting consumables, as technology such as Pulsed welding tends to be especially harsh on consumables and often requires heavy-duty options to withstand the heat of the arc for longer periods of time. For these applications, look for contact tips that are engineered with a hardened insert, making them more resistant to arc erosion and wear. They typically last 10 times longer than copper or chrome zirconium tips. Companies can regain as much as 95% of lost productivity for contact tip changes with this style by reducing planned downtime for the task. Peripherals refer to any additional equipment integrated into the robotic welding system to maximize its performance. They include items such as a nozzle cleaning station (sometimes called a reamer or spatter cleaner), anti-spatter sprayers, wire cutters and neck alignment tools. Unfortunately, some companies downplay the value of peripherals, viewing them as an unnecessary cost, and don’t realize that they can play an important role in reducing downtime and rework, improving quality and increasing productivity. Consider a nozzle cleaning station, for example. As its name implies, this peripheral cleans the nozzle of dirt, debris and spatter, typically during routine pauses in the robotic welding operation. This cleaning action helps prevent shielding gas coverage loss that could lead to weld defects, expensive rework and lost productivity. The equipment also helps the front-end consumables last longer — and longer consumable life means less downtime for changeover and less expense for replacements. The addition of an anti-spatter sprayer further improves consumable life and performance by adding an anti-spatter compound that serves as a protective barrier against spatter buildup and other contaminants. In the long run, the up-front investment in peripherals such as these can lead to measurable savings and provide a better return on investment by aiding the robot in doing what it does best: complete consistent, high-quality welds for longer periods of time than a semi-automatic welding operation. Robotic welding operations require ongoing supervision and maintenance, and that job needs to be completed by a skilled operator who has undergone the proper training. When considering an investment in robotic welding, companies should take care to evaluate the available pool of talent. As a rule, skilled welding operators and/or employees with prior robotic welding experience are the best candidates to supervise the weld cell. After the proper training, which a robotic integrator or OEM can typically provide, these employees can provide the necessary operating and troubleshooting skills to ensure the maximum uptime in the robotic welding cell. As part of the routine training, it is absolutely necessary for the operators who will be overseeing the robot to be able to schedule and perform routine preventive maintenance on the system. Implementing preventive maintenance helps minimize unnecessary downtime and keep the robotic welding system running more smoothly. If problems can be solved before they arise and the robotic welding equipment made to last longer, it can protect the company’s investment, and ensure the productivity and profitability sought by this equipment in the first place. Companies should consider vetting robotic welding integrators to determine the availability and costs associated with the training of personnel. Typically training lasts one to three weeks, depending on the certification level desired, and continuing tutorials are often available. In the end, careful planning, good equipment selection and proper training are all “must-knows” for managing a profitable and productive robotic welding operation. So whether a company is new to robotic welding or trying to improve an existing operation, knowing some key factors can go a long way in helping to gain a competitive edge and to make the most out of the investment.