MIG Welding FAQ: Best Practices for MIG Success

Estimated reading time: 6 minutes

MIG is the most frequently used welding process in general manufacturing and fabrication, thanks to its ease of use, versatility, and productivity benefits.

While MIG is widely used, some operations may still run into issues that require troubleshooting. Understanding the basics of MIG welding and following best practices for operator technique as well as gas and consumable selection can help optimize results with the process.

Q: What are the main advantages of MIG welding?

MIG offers productivity benefits when compared to some other welding processes such as TIG and Stick, thanks to its higher travel speeds and deposition rates. MIG is also considered easier for new welders to learn, so it can be a good option for operations that struggle to find skilled welders.

MIG could be utilized with either solid filler wires or tubular wires such as Metal Cored and when used with Flux Cored wires it is referred to as Flux Cored welding. Tubular wires in general can be run at higher speeds and deposit more weld metal, so they even offer higher productivity gains than Solid wires.

Q: What are the differences between MIG and TIG welding?

There are many factors to consider when choosing the right welding process for your application. These include base material type and thickness, weld appearance requirements, productivity requirements, the welding environment and available skilled labor.

TIG welding is generally used in niche applications, such as those that require high-precision welds or extremely high aesthetic quality. TIG is frequently used with special-grade materials like titanium or stainless steel. In comparison, MIG can be used in higher production applications where increased throughput is important, and it’s a good option for a wide variety of metals.

A typical travel speed in TIG welding is 4-6 inches per minute. With MIG welding, travel speeds are much higher; 6 inches per minute are considered slow, and 15 to 20 inches per minute are common. Deposition rates are also much higher with MIG welding.

Regarding training, TIG is considered the most difficult welding process to learn and master since it uses both hands. An operator may take a few months to become proficient in TIG, while a new welder could be proficient in MIG within a week or two.

Q: What is the right shielding gas for MIG welding?

Shielding gas plays an important role in determining weld penetration profiles, arc stability, mechanical properties of the finished weld, the transfer process you use and more.

The filler metal manufacturer often provides shielding gas recommendations for the type of wire being used, so it’s a good idea to first consult the wire specification sheet.

When using flux-cored wire, 100% CO2 or an 80/20 Argon/CO2 mix are common choices. When it comes to solid wire or metal-cored wire, the right gas is dependent on the transfer mode being used. A short-circuit transfer mode works with 100% CO2 gas in most cases but can still run on mixed gas. While using a pulse or spray transfer, a higher Argon content is needed, and an 80/20 Argon/CO2 is the right choice.

The base material also plays a role in choosing the right gas. Aluminum requires 100% argon, while stainless steel requires at least 98% argon.

Q: Which is better: a push or a pull technique?

The technique choice may come down to operator preference in most cases, but there are some best practices. For example, when welding aluminum, a push angle is generally better because it helps the cleaning action of the oxidation layer on aluminum, similarly uphill position, a push angle is good for visibility and penetration. While if you use Flux Cored wire to weld carbon steel then a pull angle is going to work better in this case to give enough time to the slag not to be entrapped in the weld metal.

Q: What is the proper wire stick-out?

Maintaining a proper stick-out is important to achieving the best results in MIG welding, a too-long or a too-short stick-out will affect the weld quality and appearance. A 3/8-inch stick-out is a good starting point, but operators can deviate from that based on preference, wire diameter and accessibility to the weld.

Q: What amperage MIG welding gun is needed?

To choose the right MIG welding gun, consider the specifics of the application. The wire feed speed and wire diameter are two of the most important factors in determining proper gun amperage. Are you welding heavy wall materials, like heavy equipment or heavy steel structures? Those jobs will likely require a high deposition, hence a high-amperage welding gun — such as an Air-cooled 400-amp gun with at least a 60%-80% duty cycle or above, and in some cases a water-cooled gun. If you weld lighter walls and shorter beads, you may consider a 200 to 300-amp gun.

The most common amperage choice in the industry is a 300- to 400-amp, air-cooled MIG gun. This gun can address the majority of the MIG welding applications and can run the most common wire sizes such as 0.045” and 0.052”.

A good starting point would also be the welding procedure in place that specifies the amperage needed for the weld, which would help in choosing the gun’s amperage. Another easy way is to match the welding machine amperage output, a 400-amp welder would run well with a 400-amp gun in most cases, but this might not be the most effective way to select the right amperage gun when compared to the other methods mentioned above.

Q: How can an operation make consumables last longer?

Using the OEM consumables designed to be used with a specific MIG gun and welding system is important. Because these consumables are machined to very tight tolerances and go through high-quality measures which in turn is translated into higher quality welds and longer consumable life.

Be sure to choose a contact tip that is the appropriate size for the wire diameter — an oversized or undersized contact tip will wear faster and result in poor performance. In addition, follow the gun manufacturer’s recommendations for consumable installation and changeover, check connections regularly, install and trim to the right length, select the right nozzle material, size and recess/extension, and finally clean your consumables regularly and change them when needed.

Written by Mostafa Hanafy (mostafa.hanafy@tregaskiss.com) , Market Segment Manager, Tregaskiss and Bernard. Republished with permission from Fabricating and Metalworking (August 2023).

NEW PRODUCT — ACCULOCK™ S FOR CONVENTIONAL LINER STARTER KIT — NOW AVAILABLE

NEW PRODUCT — ACCULOCK S FOR CONVENTIONAL LINER STARTER KIT — NOW AVAILABLE

The AccuLock™ S for Conventional Liners starter kit (part number: ALCSK-1) is designed to help welders convert from their current BTB MIG gun consumables to AccuLock™ S consumables.

The kit contains everything needed for welders to swap their current nozzle, diffuser and contact tip with AccuLock™ S consumables with the ability to still use their existing conventional liner. Contact your distributor for more information or to order a kit today!

BERNARD MIG GUN BUILD CHANGE — EFFECTIVE APRIL 11, 2023

Beginning April 11, 2023 Bernard has begun re-installing consumables back onto all BTB semi-automatic MIG guns so that your MIG gun arrives ready to weld. Note that guns built before April 11, 2023 will not have the consumables installed out-of-the-box and the nozzle and tip will be within a bag inside of the box. This update applies to all MIG guns, including all Miller packages that have part numbers beginning in 951.

Upfront Cost vs. Total Cost of Ownership of MIG Guns and Consumables

Upfront Cost vs. Total Cost of Ownership of MIG Guns and Consumables

Estimated reading time: 4 minutes

While it may be tempting for companies to purchase MIG welding guns and welding consumables based on price, lower upfront costs don’t always add up to savings. Less expensive products often lack in quality and bring risk to the profitability of the welding operation. This can come in the form of:

- Downtime for troubleshooting

- Shortened product life span

- Missed production goals

- Poor MIG gun and consumable performance

- Poor quality welds and associated rework

For these reasons, it’s important to look at MIG guns and consumables as more than simple commodities. Welding engineers, production managers and purchasing agents, along with other stakeholders, should instead look at the total cost of ownership of these products. Those with a higher upfront cost can help reduce risks and save money in the long term.

A look at MIG welding guns

When considering the total cost of ownership of a MIG gun, there are several factors to keep in mind. For example, less expensive guns may require more maintenance and repairs over the life span of the product. Parts like necks, handles and triggers may need frequent attention, resulting in increased expenses for replacement and downtime for changeover. With labor being the largest expense in a welding operation, time spent on activities other than welding come at a price.

Lower quality guns may also require more downtime for troubleshooting issues like poor wire feeding. This not only stops production, preventing parts from moving out the door, but it also keeps welding supervisors or others from more important tasks. When an employee’s job is to keep the weld cells running smoothly, any distraction for troubleshooting can negatively affect the productivity and profitability of the welding operation.

To lower the total cost of ownership of a MIG gun, companies should look for quality products with a long life span. Guns that offer the ability to repair the power cables are a good option. In this case, the downtime and cost for replacement is a benefit. It is less expensive to repair the cable than to buy a brand-new gun. Companies should also look at a gun’s warranty.

With heavy industrial use, a high-quality MIG welding gun typically lasts one to two years and those, like Bernard® BTB guns, include a one-year warranty. Some Bernard guns also have a lifetime warranty on triggers, switches and handles.

Considerations for consumables

Poor quality, cheaper consumables — contact tips, gas diffusers, nozzles and liners — can lead to a host of problems that increase downtime and costs. These include an erratic arc, burnbacks, birdnests and a short life span (particularly for contact tips) that can lead to rework. Such issues also increase instances of troubleshooting and make less expensive consumables pricier in the long term.

Cheaper contact tips can be prone to keyholing, or an uneven wear of the bore, and may not be as consistent in terms of electrical conductivity. Both can affect welding performance and shorten product life.

Conversely, premium consumables can lower the total cost of ownership in a welding operation. The longer they last, and the easier they are to install, the less downtime for changeover and the less expense for replacement. AccuLock™ contact tips feature a coarse thread that eliminates cross-threading and 60% of this consumable is buried in the diffuser, so it is away from heat during welding. As a result, these contact tips last two to three times longer than competitive ones. For robotic applications, AccuLock HDP contact tips last six to 10 times longer. This extended life can help increase production by reducing the number of scheduled changeovers.

QUICK LOAD™ liners are also a good option for robotic applications, as they load from the front of the robotic welding gun — safely out of the weld cell — in less than half the time needed for a conventional liner. The liner in the AccuLock S consumable system offers error-proof liner trimming without measuring, to prevent issues with wire feeding.

MIG gun and consumables trials

When it comes to MIG guns and consumables, time is money. Repairs, replacements and rework all add up and affect the total cost of ownership of these products — not to mention the company’s bottom line. Making a conversion to higher quality options can yield good results and the benefits can be verified with a MIG gun and consumables trial prior to implementation. These trials help establish a baseline for improvements and provide data that allows companies to assess the upfront cost of products compared to the cost of downtime. With this information in hand, companies can make an informed decision about alternative MIG welding guns and consumables.

Employee Training: Best Practices for Preparing New Welders

Employee Training: Best Practices for Preparing New Welders

Estimated reading time: 4 minutes

Given the industry statistics regarding the number of experienced welders who are retiring from the field, many companies are likely training more new welders than ever before. By 2023, the nation’s workforce will need over 375,000 welders to satisfy the demands of several industries. [1]

Proper new welder training is essential to help companies meet quality and productivity goals. Consistent, thorough training also helps get welders onto the production floor as quickly as possible, allowing operations to meet throughput targets and customer timelines. Underscoring the importance of employee training, a study by the National Center on the Education Quality of the Workforce shows a 10% increase in workforce education can lead to an 8.6% increase in total productivity. [2]

There are various techniques and solutions for training new welders and resources available once training is complete.

3 primary learning styles

Welding is obviously a hands-on skill, but the best type of welder training for new employees may vary based on their learning style. Understanding the differences in learning styles can help companies tailor their training to best fit the way each individual learns. The three main learning styles are: [3]

Visual learning

People who have a visual learning style prefer to absorb new information by seeing the material being presented. They tend to remember things that are written down. Tips for reaching visual learners include turning notes into pictures, charts or maps; color coding parts of new concepts in any notes; focusing on learning the big picture first before drilling down to the details; and avoiding distractions.

Auditory learning

Learners who fall into this category prefer to learn through listening; they retain information best through hearing and speaking. Tips for reaching auditory learners include having them repeat the material out loud and in their own words; discussing the material in small groups; and having them read any new information or instructions out loud.

Kinesthetic learning

This type of learner prefers to learn by hands-on training. They would rather have a demonstration of how something works than a verbal explanation. Tips for this style of learner include taking frequent training breaks; have them learn new information while doing something active; and focus on hands-on demonstrations or lab work.

Covering the basics of welding training may differ for each type of learner. For example, a visual learner may want charts and graphics showing the different welding processes or parameters they will be using, while an auditory learner may want the trainer to explain those processes and parameters to them out loud. A kinesthetic learner may want to use a virtual reality or augmented reality welding training system to learn the skills in a hands-on manner.

Post-training tips

No matter what learning style is used in training, there are many solutions and welding technologies available that can help reinforce the information with welders once they are on the production floor.

Many of today’s welding power sources include technologies such as automatic presets and parameters windows that help ensure operators are using the best settings for the application. Weld data monitoring technology is another solution that can provide guidance to welders who have less experience. For example, some systems guide welders through the weld sequence in real time and will provide alerts if a weld is missed or outside of acceptable parameters.

Choosing welding equipment and consumables that are easy to install and use is another step companies can take to help welders of all experience levels produce high-quality welds. AccuLock™ welding consumables are designed to address common challenges in semi-automatic and robotic MIG welding applications. Simplified welding consumable replacement helps increase accuracy and reduce employee training requirements.

Resources for support

Many welding manufacturers also provide resources that companies can use to support welders after the training process. These resources include training manuals and welding guides found online, and how-to videos for welding equipment and consumables that are available on manufacturer websites or YouTube channels. QR codes on the welding equipment itself can be used to access how-to guides, training or machine updates.

These resources, coupled with the capabilities and ease-of-use engineered into today’s welding equipment and technologies, can help companies train new welders faster and support them once they are in production.

[1] American Welding Society: https://www.aws.org/foundation/page/workforce-development

[2] National Center on the Education Quality of the Workforce https://onlinemba.wsu.edu/blog/the-four-benefits-of-employee-training/

[3] Missouri State University: https://www.missouristate.edu/Assets/busadv/p-30.pdf

Making a MIG Gun Last in Harsh Manufacturing Environments

Making a MIG Gun Last in Harsh Manufacturing Environments

Whether it’s a high amperage application, high or low ambient temperatures, or humidity, harsh manufacturing environments can be tough on welding equipment — including MIG guns and consumables. Confined, cluttered or dirty weld cells can also negatively affect this equipment.

Cleaning and organizing the weld cell, plus areas upstream and downstream, can help prevent some issues — for example, damage to welding gun cables caused by forklifts running over them. However, operators can’t change factors such as heat or cold or the amperage required for the job. For that reason, it’s important to look for a durable MIG welding gun and consumables and know how to protect them. Not only does that help minimize costs for replacement, but it also supports productivity by reducing downtime for changeover.

What to look for

One of the best defenses against the elements in a harsh manufacturing environment is to choose a MIG gun with robust components and make certain it’s the best option for the job. Consider these factors.

Duty cycle

This is the most important factor in selecting a MIG gun for any operation, but especially in a harsh environment. Duty cycle is the amount of arc-on time within a 10-minute period that a gun is capable of being used. Manufacturers in the U.S. rate their MIG welding guns according to the National Electrical Manufacturers Association (NEMA), with the rating reflecting the temperatures at which the gun or cable becomes too warm for use. For example, a gun may be rated at 400 amps and 100% duty cycle, meaning it can weld the entire 10 minutes at 400 amps (or even longer at a lower amperage) without discomfort to the operator.

In areas of high heat and humidity, it is helpful to use a MIG gun offering 100% duty cycle and higher amperages than needed for the application. If a welding shop is experiencing 80% humidity and it is 100 degrees F outside, that ambient temperature will reduce the duty cycle — a 400-amp gun may drop from 100% duty cycle to a 60% duty cycle range.

Handles

MIG gun handles should be manufactured with materials designed to withstand heat. Those with added glass in the plastic mold material are particularly adept at resisting wear in harsh environments. Tubular handles are also an option, as they tend to be a bit larger, and they have a slight air gap between the handle and the power cable that adds to its durability and heat tolerance. However, each handle material and design can have its own pros and cons. High glass content will create a more brittle handle, while more malleable materials may withstand less heat but not break as easily if abused.

Trigger

Trigger designs vary by manufacturer. The best option to protect against harsh elements is a micro-switch trigger, which is sealed. MIG guns with straight handles typically have a trigger that is enclosed to protect against dirt and debris. Avoid contact triggers, as these feature a spring and two contacts that touch each other when the operator presses down on it. Dirt can get inside of these triggers and break the contacts, preventing good electrical connections.

Neck

A MIG welding gun neck with aluminum armor on the outside is a durable choice. This type of neck is also lightweight, so it is more comfortable for the operator. MIG gun neck grips can also increase comfort, as well as control.

Power cable

Look for a power cable with a thick rubber outer jacket. While this type of cable may add some to its stiffness and weight, it will last longer. It can better take the abuse of being dragged on the floor, run over edges and exposed to hot materials. There are also power cable jackets that further protect power cables in harsh environments. A good jacket option is one with a tubular design versus one with Velcro or buttons. A power cable with higher-quality grades and higher amounts of copper adds to its durability and performance, as well.

Consumables

Welding contact tips, nozzles and gas diffusers made from quality copper or chrome zirconium are reliable complements to a sturdy MIG gun. Typically, higher-quality welding consumables cost more upfront; however, they last longer. Having fewer changeovers during shifts can save money for labor and replacement consumables in the long run. Contact tips, like those in AccuLock™ S consumable systems, have 60% of the tip buried within the gas diffuser. This keeps heat from the weld away from the tip, so it lasts longer. Shielding gas also cools the contact tip tail to protect it.

Maintain and protect

Preventive maintenance is critical in any welding operation, but especially in harsh manufacturing environments. Purchasing a gun that is repairable and can be maintained versus thrown away is a smart investment. In the long term, operators and maintenance personnel can gain more life from the gun even when exposed to heat, humidity and other elements.

Periodically, remove the welding gun liner and blow out any dust or debris that accumulated with compressed air. Take care not to drag the liner on the ground, where it can pick up more dirt or inadvertently become damaged.

At the start of every shift, especially when operators share MIG guns, check all connections. Tighten connections along the length of the gun — between the welding contact tip, gas diffuser, neck, power cable and power pin. Also check that the screws on the handle are tight and the trigger is functioning. When using a MIG welding gun with a rotatable neck, be certain to tighten it to avoid wire feeding problems.

Being mindful

The best defense to protect a MIG gun used in a harsh manufacturing environment is to make sure to select a durable one in the first place. Look for quality components and take care to schedule preventive maintenance. Treat the MIG welding gun just like any other piece of equipment in the welding operation, caring for it with regular inspections. Doing so can increase its lifespan and help prevent downtime and the cost for replacement.

PRODUCT UPDATE – Tregaskiss TOUGH GUN® TT4 Reamer Robotic Nozzle Cleaning Station Online Configurator and Reverse Lookup Tools

PRODUCT UPDATE – Tregaskiss TOUGH GUN® TT4 Reamer Robotic Nozzle Cleaning Station Online Configurator and Reverse Lookup Tools

Tregaskiss introduces a new online configurator for its TOUGH GUN® TT4 reamer robotic nozzle cleaning stations. The new mobile-friendly configurator allows users to quickly and easily customize their analog or ethernet reamer for their exact application. Users simply follow a series of steps to configure a reamer model, first selecting the V-block and cutter blade to match the outside diameter (OD) and bore of their robotic MIG gun nozzle. Users can then select from various add-ons, including a wire cutter or nozzle detect. Tregaskiss also offers the option to choose accessories sold separately, such as a reamer stand, anti-spatter liquid and an anti-spatter multi-feed system.

After choosing all desired components, the configurator provides a summary of the selections, along with a part number for the reamer. Users can access downloadable replacement parts lists, exploded view diagrams and other valuable takeaways that they can print, save in PDF format for later, or share via email.

Along with the online configurator, a new reverse part number lookup function for Tregaskiss TOUGH GUN® TT4 reamer robotic nozzle cleaning stations is available. By entering a fully configured TOUGH GUN TT4 reamer part number, users get access to a downloadable detailed replacement parts list and other relevant resources specific to their configuration.

Users can visit Tregaskiss.com/ConfigureMyGun to utilize this online configurator or reverse lookup function.

Bernard and Tregaskiss Release NEW MIG Welding Guns & Consumables Catalog

Bernard and Tregaskiss Release NEW MIG Welding Guns & Consumables Catalog

BEECHER, Ill./WINDSOR, Ontario. (March, 2023) — Bernard and Tregaskiss have announced the availability of a joint MIG Welding Guns & Consumables catalog.

The 46-page, full-color catalog includes a consumable comparison chart to compare contact tip, nozzle and diffuser types across the brands’ available consumables offerings, along with a consumables and MIG gun series compatibility chart to guide users in their selection.

The catalog offes easy-to-read key features and part numbers for its products and is organized by product category, first highlighting the brands’ exclusive AccuLock™ S and AccuLock R Consumables — both designed to reduce downtime and improve welding performance.

Also included in the catalog are product details and configurator overviews for customizing Bernard® Semi-Automatic MIG Guns, Tregaskiss® Robotic MIG Guns, Clean Air™ Guns and more. Tregaskiss Fixed Automatic MIG Guns for hard tooling applications are also featured.

Each page includes website quick links with URLs users can visit to learn more about a specific product, plus service and support contact numbers and directions to explore online resources, such as videos and product configurators.

The catalog can be downloaded as a PDF or ordered as a printed copy at Tregaskiss.com/literature.

Bernard AccuLock S Consumables Now on Select Miller® Packages

Bernard AccuLock S Consumables Now on Select Miller® Packages

BEECHER, Ill. (March 7, 2023) – Bernard has announced that AccuLock S consumables will now be standard on its BTB MIG guns included in select packages from Miller Electric Mfg. LLC. These will replace its Centerfire™ consumables that previously shipped with the equipment.

An AccuLock nozzle and contact tip will be included in these packages, along with a newly designed gas diffuser that is compatible with Bernard conventional liners. This diffuser will simplify conversion of existing fleets of BTB MIG guns from Centerfire consumables or TOUGH LOCK® consumables to AccuLock S consumables. To enjoy the full benefits of the AccuLock S dual-locked liner system, users can choose to upgrade their MIG guns later by changing the diffuser, liner and power pin cap.

The AccuLock S consumables will be standard on the following Miller packages:

- Suitcase® 12RC

- ArcReach® Suitcase 8 and 12 (on Bernard BTB MIG guns only)

- Deltaweld® Systems

- XMT® 350 FieldPro™ Systems

- XMT 450 Systems

- Continuum™ Systems

- 20 Series

- S-74 MPa Bench Feeders

- Intellx™ Wire Feeders

- Intellx Swingarc™

Bernard is providing end users with the ability to configure Bernard BTB MIG guns with AccuLock S consumables for conventional liner diffusers through its online configurator. Packages that have Dura-Flux™ and PipeWorx guns will not include AccuLock S consumables.

For more information, visit Tregaskiss.com/acculock_conventional/.

# # #

Using Root Cause Analysis to Address Welding Consumable Issues

Using Root Cause Analysis to Address Welding Consumable Issues

Estimated reading time: 4 minutes

Troubleshooting problems with welding consumables can be time-consuming and expensive. From the associated downtime to the cost of replacing contact tips, diffusers, nozzles and liners, companies stand to lose productivity and potentially miss production goals.

Applying root cause tools can help expedite the process. These are structured methods to narrow down the true cause of a problem and determine an exact solution.

At a high level, root cause analysis follows several key steps:

- Defining the problem

- Collecting information

- Identifying issues that are contributing to the problem

- Determining the root cause

- Recommending and implementing the solution

To successfully implement root cause tools, it’s important to keep an open mind about possible causes that are contributing to welding consumable problems and to be patient, as it may take time to determine a cause and solution. Analytical thinking, along with being thorough and unbiased in the assessment, is a must.

The 5 Whys

The 5 Whys is a common and simple root cause tool to apply to welding consumable issues. It involves asking “Why?” five times, and providing answers, to drill down to the root cause. In some instances, the solution may become apparent after fewer than five questions. Other times, it may take more. It is also possible that the questioning may become circular and require branching off into another line of questions. Once the root cause is identified, companies can home in on the right solution and determine ways to prevent further problems.

For example, companies may ask the following if there are issues in a semi-automatic welding operation:

- Why do we have an erratic arc? Because the welding wire is feeding poorly.

- Why is the welding wire feeding poorly? Because the wire feeding path is blocked.

- Why is the wire feeding path blocked? Because the liner is kinked up.

- Why is the liner kinked up? Because it was trimmed incorrectly.

- Why was the liner trimmed incorrectly? Because welding operators didn’t measure it properly

Knowing this information, companies may determine they need to train welders to use a liner gauge during trimming and installation. AccuLock™ S consumables are another option, as these have a liner that eliminates liner trim length errors without the need to measure. The liner locks and aligns at the front and back of the gun to provide a flawless wire feed path.

To gain the best results from The 5 Whys, engage employees who have hands-on experience with the welding process. Quality engineers are also great resources to include.

Failure Modes & Effects Analysis (FMEA)

FMEA assesses how a failure could occur, its causes and what the potential consequences of a failure would be. FMEA follows the same logic as The 5 Whys to drill down to a root cause. Engineers use this tool proactively during the design of components like welding consumables. Companies can also use FMEA over the course of using these products as a troubleshooting method.

Keeping with the example of welding consumables, a FMEA for troubleshooting may look like this in a robotic welding operation:

- Failure mode: Off-location welds.

- Potential consequence: Non-conforming parts.

- Potential cause: Cross-threaded contact tip.

- Current process controls: Train employees to install contact tips correctly.

Potential solution: Use a contact tip that can’t be cross-threaded. These can be found in the AccuLock R consumables system.

When using FMEA or The 5 Whys to troubleshoot welding consumables issues, it’s important to look at all aspects of the situation to accurately determine the root cause. While it may seem time-consuming, investing in the use of these methods can actually save time in the long term — not to mention frustration and costs.

PRODUCT CHANGE — AccuLock™ Conventional Liner Gas Diffusers

PRODUCT CHANGE — AccuLock™ S Conventional Liner Gas Diffusers — O-Ring Color Change to Gray

All AccuLock S conventional liner gas diffusers began shipping with a gray o-ring instead of a black o-ring on February 22, 2023. The gray o-ring makes it easier to tell the difference between an AccuLock S dual-locked liner gas diffuser and an AccuLock S conventional liner gas diffuser.

For reference, the AccuLock gas diffuser part numbers listed below will be assembled with a gray o-ring:

| Part Number | Description |

| D-A1-C | AccuLock S Gas Diffuser, Large Nozzle, Thread-On, Conventional Liner |

| D-A2-C | AccuLock S Gas Diffuser, Large Nozzle, Slip-On, Conventional Liner |

| DS-A1-C | AccuLock S Gas Diffuser, Small Nozzle, Thread-On, Conventional Liner |

| DS-A2-C | AccuLock S Gas Diffuser, Small Nozzle, Slip-On, Conventional Liner |

Welder Training Tips to Help Improve Productivity

Welder Training Tips To Help Improve Productivity

Estimated reading time: 6 minutes

Improving productivity in semi-automatic operations isn’t simply about welding faster and working harder. Instead, there are ways to create consistency in the process and support quality so that companies can avoid downtime that adversely affects throughput.

When training new welders, it’s important to provide a solid foundation of knowledge to achieve the best results. Taking the time to establish and expand welders’ skill sets shows welders companies are invested in them, and as welders gain more experience, they become more confident. The aim is to empower them and provide all the information necessary to be productive.

To instill good habits from the start, consider some key training tips.

Put safety first

A safe welder is a productive welder. By training new welders to follow welding safety protocols, there is less risk of lost productivity due to injury. Wearing the appropriate personal protective equipment (PPE) is important. This includes a properly fitted helmet, safety glasses, flame-resistant jacket or sleeves, welding gloves and steel-toed, rubber-soled boots. If the process is prone to higher levels of fume generation, correct use of a respirator is necessary. Train welders to read and follow all equipment labels and their owner’s manual carefully before operating welding equipment. Training also includes checking the power source ground, securing workpieces in the best possible manner and keeping their heads out of the weld plume when welding.

Establish consistent weld prep

Following best practices for weld prep supports high weld quality, reduces rework and scrap, and improves productivity. As part of new welder training, welders should understand their power source settings, type and levels of the shielding gas being used, and how to clean the base material. Checking that all welding consumable connections are tight can minimize electrical resistance that could lead to burnbacks (the formation of a weld in the contact tip) and downtime for tip changeover.

Install welding consumables correctly

Downtime to address liner issues is common in semi-automatic welding operations and is typically caused by incorrect installation. This can lead to bird-nesting (a tangle of wire in the drive rolls), poor wire feeding, an erratic arc, wire chatter, burnbacks and more. Always use a liner gauge when trimming a liner; or consider a consumable system like AccuLock™ S, which provides error-proof liner installation without measuring. The liner locks and is aligned to the power pin and the contact tip to ensure proper wire feeding. New welders should also learn to install and tighten contact tips according to the consumable manufacturer’s recommendation.

Focus on comfort

Training welders to pay attention to their posture and the angle they hold their MIG welding gun can help reduce fatigue and the risk of welding-related musculoskeletal disorders that lead to lost productivity. Whenever possible, welders should position themselves so they are welding the workpiece in the range between their waist and shoulders. This may require a work stool or adjustable chair. Welders should also keep their hands and welding gun at or slightly below elbow height. Gaining good visibility to the weld joint can encourage proper posture.

Follow welding procedures

Welding procedure specifications (WPS) are a means to create consistency in the welding operation by taking the guesswork out of the process. This document outlines welding parameters, filler metal type and diameter, wire feed speed (WFS), weld pass sequence and more. Training new welders to follow the details in a WPS can help ensure that they produce quality welds and remain productive.

Use the right equipment

New welders should be trained to use the best equipment and tools for the job — and ones that best suit them. A MIG welding gun that fits the welder’s hand comfortably will help maximize their time when welding. Using a hammer for repositioning a part, as opposed to the MIG gun itself, can prevent damage to the gun that leads to downtime for repairs or replacement.

Likewise, having the correct wrench for installing gas diffusers or welpers for tightening contact tips helps ensure snug connections and lessens the opportunity for issues. Using the wrong tools or not tightening parts properly leads to loose connections that cause electrical resistance. This, in turn, increases heat and wears out the equipment prematurely.

Employ proper techniques

Welding techniques vary according to the process, the welding position and the thickness of the base material. For example, when MIG welding with solid or metal-cored wire, welders need to learn to use a push technique, while a flux-cored process requires a drag technique. Train welders on the proper gun angles for flat, horizontal and out-of-position welding applications so they are able to fill the joint with the appropriate amount of weld metal and avoid issues like lack of fusion.

Recognize signs of trouble

Training new welders to quickly identify issues in the welding process can minimize downtime for troubleshooting. They should be given the guidance to identify the causes of common problems like porosity, burnbacks, poor deposition and more, along with their solutions. Welders should also be able to recognize signs that equipment needs to be repaired or replaced — for example, a welding contact tip that is keyholing (wearing at the bore unevenly) or a gun that has nicks in the power cable. Companies can provide troubleshooting cards with quick checklists to keep in the weld cell as reminders.

Keep communication open

Clearly communicating expectations to new welders and having supervisors who are responsive to questions are vital parts of training. It is about both learning and listening. As training continues and welders grow their skill sets, it’s important to establish two-way feedback. This way everyone can find common ground on what best practices could be. In some cases, new welders may identify a way to improve the operation based on experience they have from another job.

Successful new welder training

When companies commit to providing thorough new welder training, the aim is to establish skills that lead to consistency in quality and reduce downtime. The more they can avoid secondary work or additional processes, the better productivity will be. Plus, supporting the comfort and safety of welders can help make sure they perform their best every day, build confidence and help retain them as employees.

At a Glance: Cobots and the TOUGH GUN® CA3 MIG Gun

At a Glance: Cobots and the TOUGH GUN® CA3 MIG Gun

Estimated reading time: 4 minutes

Companies today continue to face a shortage of qualified welders, but the demand for product has stayed the same — or in many cases, increased. Turning to new solutions to keep up with production can help keep the welding operation running smoothly and quickly.

For many companies producing a high mix and low volume of parts, investing in a cobot can be a smart business decision. A cobot, or collaborative robot, relies on interaction from a welding operator but provides faster speeds than semi-automatic welding. Cobot welding is also a less expensive alternative to robotic welding and takes up less space.

To operate the cobot, the welding operator uses a tablet to program the desired weld and moves the cobot welding gun to the beginning of the joint. While the cobot is welding, the welding operator can work on other activities, helping companies make the most of the available labor.

Tregaskiss TOUGH GUN CA3 robotic air-cooled MIG gun

Tregaskiss designed its TOUGH GUN CA3 to help companies gain the most from their cobot. It provides several key benefits.

Durability

The TA3 gun is designed and engineered with the same trusted and robust components as other Tregaskiss guns and is proven to last in high-volume welding operations.

Productivity

Combined with AccuLock™ R consumables, the TOUGH GUN CA3 welding gun can help ensure greater productivity. The contact tips last longer so there is less downtime for changeover. When routine changeover is necessary, it can be done quickly and easily so the cobot and welding operator spend more time producing parts.

Reliability

The TOUGH GUN CA3 MIG gun has metal-to-metal keyed connections to hold it in place in the mounting arm. These also keep the aluminum-armored neck firmly connected to the gun, so users can depend on the gun to perform consistently.

Simplicity

The gun is easy to maintain when needed — necks can be changed with one tool by loosening a small number of fasteners. Operators can also easily install QUICK LOAD® liners from the front of the gun. For operations that have semi-automatic welding, companies can streamline inventory by using the same AccuLock contact tip on their MIG guns.

Compatibility

The CA3 gun is compatible with cobots from FANUC®, Yaskawa® Motoman® and Universal Robots (UR) and most welding power sources. Power pin options are available for machines from Miller®, Lincoln®, Fronius®, Tweco®, Panasonic® and more.

Tregaskiss offers customizable options according to style and neck, consumables, cable length, wire size and power pin through the online configurator.

Cobot welding best practices

Along with having a reliable cobot MIG gun, there are some best practices to consider for cobot welding.

- Provide welding operators with proper training. Programming is relatively easy using a simple tablet interface, and training can be done quickly. In many cases, welding operators are able to share their knowledge with other employees to expedite training.

- Follow safety precautions and use proper Personal Protective Equipment (PPE). Read and follow the cobot and cobot gun owner’s manuals. The cell where the cobot is located should be surrounded by welding curtains to protect the operator and others from arc flash.

- Tooling, fixtures and other equipment added to the robotic cell after delivery may change the type and number of hazards present in and around the cobot system. Conduct a safety review and perform another risk assessment after the installation of any additional equipment to the robotic cell.

- Understand the rating of the gun and make sure that it is appropriate for the application and prevent overheating. The CA3 gun offers 350 amps at 100% duty cycle with mixed gases.

- Be sure the robot and gun can move freely and that the power cable doesn’t interfere. Operators should also stand clear of the moving cobot.

- Understand the tool center point (TCP) and how far the cobot and cobot gun can reach to ensure quality.

As with any welding application, contact a trusted cobot welding gun or cobot manufacturer with questions or reach out to a local welding distributor.

PRODUCT CHANGE — CONE NUT AND END FITTING

PRODUCT CHANGE — CONE NUT AND END FITTING ON BERNARD® BTB MIG STRAIGHT HANDLE MIG GUNS WITH HYTREL® POLYMER CABLE — EFFECTIVE JANUARY 3, 2023

Our product offering is regularly assessed to ensure focus on customer needs and opportunities to innovate our product portfolio, so we can continue to deliver sustainable value to our customers.

Starting 1/3/2023, there will be part number changes to the cone nut/end fitting found on Bernard BTB straight handle MIG guns with Hytrel polymer cable. Note that although the parts will look different, the functionality remains the same. These part number changes are also reflected in the current BTB MIG Gun Owners Manual.

| Current Part Number | New Part Number | Type |

| 308 | 1680087 | End Fitting |

| 408T | 1680088 | End Fitting |

| 409 | 1540003 | Cone Nut |

| 509 | 1540004 | Cone Nut |

| 608-1 | 1680089 | End Fitting |

| 609 | 1540004 | Cone Nut |

Should you have any questions or need further assistance, please contact your local ITW representative.

5 Tips for Improving Weld Quality

5 Tips for Improving Weld Quality

Estimated reading time: 7 minutes

Establishing consistent levels of weld quality is important for attaining production goals and a better bottom line in semi-automatic welding operations. However, there are many factors that can negatively impact those efforts, including a lack of skilled labor, inadequate or aging equipment or using the wrong welding consumables.

To avoid costly rework associated with poor weld quality, it’s critical to implement proper welder training. Evaluating the welding operation on a regular basis for issues can also help, along with following these key tips.

No. 1: Size contact tips correctly

Welding contact tips are available in a range of diameters — typically 0.023 to 1/8 inches — to accommodate different welding wire sizes. The wire packaging, in part, determines what size contact tip is appropriate to support good weld quality.

Welding wires in larger drums — 500 pounds or more — have a larger cast and are flatter so there is less degree of arc. This means there is less opportunity for the wire to make consistent contact when feeding down the bore of the contact tip, resulting in an erratic arc and weld quality issues. To avoid problems when using copper and chrome zirconium welding contact tips (with Bernard and Tregaskiss consumables), undersize them for the diameter of wire. For example, match an 0.045-inch wire to a 0.039-inch contact tip. For other manufacturers’ contact tips, request recommendations.

Copper and chrome zirconium contact tips can be matched size for size with wire on spools or in drums less than 500 pounds since the wire has a tighter cast.

For AccuLock™ HDP contact tips, the wire and tip size can be matched regardless of the welding wire drum or spool size.

No. 2: Size and change over liners properly

As with contact tips, welding liners are available in various diameters and ranges, from 0.035 to 0.045 inch or from 0.045 to 1/16 inch. To avoid issues like burnback (the fusing of a weld in a contact tip), poor wire feeding and an erratic arc that can be detrimental to weld quality, match the diameter of welding wire to that of the liner. This supports the wire as it feeds through the liner.

It’s equally important to trim the liner properly. A liner that is too short can create wire chatter, an erratic arc and bird-nesting (a tangle of wire in the drive rolls). If the liner is too long, it can cause the wire to weave. Both situations can cause poor welds and, potentially, rework.

Always use the gauge provided by the manufacturer to ensure that the liner is trimmed correctly. The AccuLock S consumable system is also a good option, as it provides error-proof liner replacement. The liner loads through the neck at the front of the gun and is locked and trimmed flush with the power pin at the back of the gun, which eliminates the need to measure.

No. 3: Keep electrical resistance low

Electrical resistance — or interference with the flow of electricity in a semi-automatic MIG gun’s circuit — generates heat and can impede weld quality by negatively impacting the gun’s components. There are several causes that can be rectified to prevent issues such as inconsistent weld appearance or an erratic arc.

Through ongoing use, connections begin to wear and loosen, leading to electrical resistance. Address this problem by tightening connections between the gas diffuser, gun neck and handle, as well as the connections from the power cable to the power pin and wire feeder.

Power cable wear that results in hotspots can also lead to electrical resistance. This wear may not always be visible, so as a course of troubleshooting, operators should consider this problem as a cause of poor weld quality. Replace the cable as necessary to prevent issues. Likewise, increased electrical resistance can occur in the gun handle, since it is an area of high use and bending. Look for signs of wear and replace as needed.

No. 4: Be mindful of cleanliness

There are various aspects of cleaning and weld prep that can help support good weld quality. Always follow proper procedures for cleaning the base material to prevent defects like porosity that can be caused by welding through dirt, oil and debris.

It’s also important to be proactive about cleaning consumables. For example, weld spatter buildup in the nozzle or in the ports in the gas diffuser can hinder shielding gas coverage, which also leads to porosity. Clean or replace these consumables when excessive spatter is evident. Operators can also apply anti-spatter compound to the consumables by dipping the front inch and a half of the nozzle into the liquid. Use the anti-spatter compound sparingly to avoid damaging the nozzle insulator.

Storing consumables in a clean area minimizes the opportunity for dust, oil or other contaminants to adhere to the surface of the welding contact tip, nozzle and diffuser and adversely affect weld quality. A covered container with compartments for each welding consumable is a good option to protect them.

Also consider how to handle the welding liner during changeover. Be careful not to drag the liner on the floor while feeding it into the gun, since doing so can cause debris to collect on it and be pulled into the gun.

No. 5: Plan for inspection and maintenance

Preventative maintenance and ongoing care of the MIG gun and consumables can go far in supporting high weld quality. Set a schedule to inspect, maintain and repair the components.

Although often overlooked during regular inspections, the O-rings found throughout the gun are important to assess. If they start to degrade or break, they can cause shielding gas leaks that lead to porosity and potentially extra costs for shielding gas if the operator increases gas flow to compensate for the leak. Check O-rings on the power pin, gas diffuser and liner during routine preventive maintenance and replace these components as needed.

Look for damage to the power cable, such as nicks or tears that can impede gas flow. Visually inspect the gun handle for cracks or missing screws and the trigger for sticking or malfunction. Repair or replace as necessary.

Last, inspect the welding contact tip for keyholing (an oblong wear of the bore); this can cause drifting wire and arc start failures that affect weld quality.

Long-term results

Improving weld quality is a matter of ongoing evaluation. Supervisors and managers overseeing semi-automatic welding operations should regularly consult with welding operators to make sure they are following best practices. Ongoing training and quickly troubleshooting issues can also support good weld quality and prevent costly downtime and rework.

Is a Water-Cooled Robotic Welding Gun Necessary?

Is a Water-Cooled Robotic Welding Gun Necessary?

Robotic welding operations can be tough on equipment. The heat from the welding arc, along with reflective heat from the base material and resistive heat from the electrical components, can wear on consumables and the robotic welding gun. In some cases, implementing a water-cooled robotic MIG gun is the answer, but many times an air-cooled model can handle the job.

Water-cooled robotic welding guns are designed to handle high amperage applications, typically above 400 welding amps at 100% duty cycle. They are used for longer welds and multiple passes on thicker material with larger welding wire diameter (above 0.052 inch), such as those found in heavy equipment manufacturing.

That said, water-cooled guns are more expensive upfront compared to their air-cooled counterparts and require the additional expense of a water cooler. These guns operate by circulating a coolant from the water cooler through hoses in the power cable to the gun and neck, then returning the coolant to the cooler to release the absorbed heat. Due to the complexity of this design, there are more potential failure modes, so maintenance and repairs cost more over the life of the gun. Given the current shortage of skilled labor, it can be difficult to find welding operators who can take on these tasks. That can lead to downtime and lost productivity.

For these reasons, companies need to ask: Is a water-cooled welding gun necessary? Often, companies may be using this type of gun because it’s what’s always been on the plant floor, or they think they need the extra protection from the heat of the application. They may even be trying to protect the consumables from overheating. That doesn’t mean that a water-cooled welding gun is the best option.

When air-cooled makes more sense

Air-cooled robotic welding guns use the ambient air, shielding gas and arc-off time to dissipate heat. Their design is simple and easy to maintain since they have fewer parts than water-cooled models. A lower upfront cost and less expense to care for the guns make them an appealing alternative to a water-cooled gun. And, in several instances, these guns are a better option for a welding operation.

Duty cycle factors into using an air-cooled robotic welding gun. Duty cycle refers to the number of minutes a welding gun can operate at full capacity in a 10-minute period without overheating. If the gun can operate the full 10 minutes, then it offers 100% duty cycle. However, many applications do not require 100% duty cycle and therefore wouldn’t benefit from a water-cooled gun that offers that capacity. In this case, it is possible to use a 350-amp air-cooled gun and run it at a lower duty cycle: for example, 50%. An air-cooled robotic MIG gun will heat up and plateau at a certain temperature. The operator overseeing the application will need to be cognizant of the duty cycle and welding duration and adjust the application accordingly.

In applications with shorter weld requirements, it’s also possible to configure a robotic welding cell to use air-cooled robotic welding guns. On a robotic line, there are often multiple robots welding at the same time. If one robot only welds for one minute and a second robot welds for two minutes, then the air-cooled gun on the first robot has time to cool down as it waits for the other robot to finish its weld. In essence, the robotic welding gun on the first robot would be working at 50% duty cycle as compared to the second robot.

For companies using a water-cooled robotic MIG gun to keep consumables from overheating, a simple change of consumable type combined with an air-cooled gun is a better, and less costly, option. Consider changing from a copper contact tip to a chrome zirconium, since it can withstand heat better. Also, high-performance consumables like AccuLock™ HDP contact tips can significantly extend tip life, even in hard pulsed robotic welding applications. They can last six to 10 times longer than copper and chrome zirconium tips. While these contact tips have a higher upfront cost, the lower expense of an air-cooled robotic welding gun means the reduction in downtime and higher productivity saves money in the long term.

Simplifying the robotic welding operation

The goal of investing in robotic welding is to increase productivity, improve quality and reduce costs. Using an air-cooled robotic welding gun, when possible, can help companies gain these benefits. The lower upfront cost and total cost of ownership of this equipment means a better bottom line.

From Consumables to Communication: Reducing Human Error in Welding

From Consumables to Communication: Reducing Human Error in Welding

Estimated reading time: 4 minutes

Human error can take its toll on welding operations, leading to downtime and lost productivity, poor quality and increased costs. It can result from a variety of factors. An operator may know how to manage a process, but periodically misses a step or forgets to complete a task. Or an operator may believe he is conducting a task in the correct manner, but it is wrong.

To reduce problems, it’s important to provide proper training to semi-automatic and robotic welding operators. This includes not only training on the welding process, but also on how to spot errors when they occur.

Companies may want to rely on principles of poka-yoke to help. These principles could be applied in several ways in a welding operation.

- Elimination: Remove or change parts of the welding process that cause problems

- Prevention: Investing in equipment or processes that prevent errors

- Replacement: Substitute consumables with ones that are more consistent

- Facilitation: Streamline operations to reduce the risk of a welding operator causing an error

- Detection: Identify errors early and correct them before they lead to costly rework

- Mitigation: Find ways to reduce the impact of errors on the welding operation

With these high-level, error-proofing ideas in mind, it’s possible to put them into action in several specific ways.

Color-coded parts

Investing in welding consumables with color-coded parts can help eliminate confusion during installation. AccuLock™ S liners and power pin caps are color coded to make it easy to identify which power pin cap is compatible with which liner. For example, power pin caps with red washers are compatible with liners that have red shrink tube and so on.

Welding procedures

Implementing a welding procedure specification (WPS), and training operators to follow it, can help ensure consistent, high-quality welds. A WPS outlines details on the welding process and parameters, weld pass sequences, filler metal type and size, and more.

Error-proof consumables design

For operations with a mix of welding arcs or for all automated welding operations, AccuLock R consumables are designed to prevent errors associated with cross threading during installation. They feature a long contact tip tail that aligns in the diffuser prior to the thread engaging. This allows operators to install the tip easily and accurately. The AccuLock S welding gun liner also offers error-proof liner trimming with no measuring required for semi-automatic welding operations.

Long-lasting consumables

Consumables that last longer require less changeover, which means less interaction by the welding operator in the welding cell and less potential for errors. AccuLock contact tips offer a longer lifespan, particularly the AccuLock HDP tips. These last up to ten times longer than standard contact tips and are designed for use in pulsed MIG welding applications, where waveforms tend to be harsher on tips.

Inventory reduction

Taking steps to simplify inventory by having a lower variety of consumables can help prevent errors during changeover. The AccuLock S and AccuLock R consumable systems share a common contact tip, so the tip can be used in Bernard semi-automatic MIG guns and Tregaskiss robotic and fixed automatic guns.

Communication and reporting

Keeping open lines of communication among welding operators and with management is an important way to minimize and rectify errors. Knowing what is expected in the welding process is a good start, as is reporting errors when they occur so that they can be fixed and don’t lead to further complications.

Preventing errors in a welding operation requires attention to detail, a commitment to making improvements, and collaboration among welding operators and management. Everyone needs to take a vested interest in the process, knowing that it will help improve quality and productivity — and ultimately make everyone’s job easier.

Choosing Between Fixed Automatic, Cobot and Robotic Welding

Choosing Between Fixed Automatic, Cobot and Robotic Welding

Estimated reading time: 5 minutes

No doubt manual, or semi-automatic, welding has its place across the industries — general fabrication and manufacturing, shipbuilding and more — and it will continue to be an important process for many applications. There are times, however, when companies need to turn to welding automation to augment or replace portions of their operations. Some may benefit from fixed welding automation, while other operations lend themselves to either cobot welding or automated (robotic) welding.

At a high level, companies tend to move to one of these types of welding processes for similar reasons: to improve quality, increase welding productivity and/or lower costs. Some companies may be responding to an increase in demand from customers or want to gain a competitive edge by supplementing their operations with automation. In certain cases, companies may replace some semi-automatic welding cells, shifting welding operators to oversee the automated operation. These systems always require interaction with an operator for loading and unloading parts, programming and troubleshooting when necessary.

To implement the right solution and successfully operate it requires careful planning. A robotic integrator or equipment manufacturer can help, and they can also provide a thorough calculation to help determine the expected return on investment (ROI).

So, when is it time to add an automated welding solution? And which one is the best for a given application?

Fixed automation

Companies that find themselves with very large parts that are difficult to weld in a timely or repeatable manner with a semi-automatic process may want to consider fixed welding automation. This process is well suited to high-volume operations with a low variety of parts, such as structural beams or railcars requiring long, continuous welds or pipe that requires circular welds. The investment in fixed welding automation equipment is relatively low, but it can provide a reliable payback by increasing productivity.

Companies can choose from two options:

- Tooling that holds the part in place combined with a fixed automatic welding gun that moves the length of the weld joint on a track. This is a good option for long, linear welds.

- A fixed automatic welding gun held in place by tooling while the part moves. This setup works well for pipe, which can be rotated.

Because there isn’t a lot of flexibility with tooling, companies investing in fixed welding automation need to consider their long-term plans and the parts they will produce.

Cobot welding

Companies seeking greater versatility in their high-mix, low-volume operations or those needing to produce longer welds than possible with a semi-automatic process could benefit from cobot welding. Those who are interested in the faster speeds associated with welding automation but have limited space or capital to invest may also want to consider the switch. Cobot welding systems are less expensive than robotic welding systems, have a smaller footprint and don’t require the guarding that a robot would.

Since a welding operator works side by side with the cobot, he or she can be in the cell with the equipment with a relatively low safety risk. Cobots are also portable, allowing companies to address multiple applications in the facility without the need to invest in additional equipment.

Training requirements are minimal compared to robotic welding, with straightforward programming on a tablet, and setup is relatively quick. These factors are important for companies struggling to find and retain skilled labor and those seeking productivity increases.

During operation, the operator sets the cobot welding gun at the starting point to put the welding in motion. The cobot is designed to complement the work that the welding operators are doing and allows them to attend to other tasks like grinding while the cobot is welding.

Robotic welding

When a company is falling short of its production goals, experiencing weld quality issues or facing increased customer demands, it may be time to invest in a robotic welding system. While smaller operations can benefit from this process, robotic welding systems especially excel at high-volume, low-variety applications. The facility must have the appropriate space available; robotic welding cells typically take up more room than a cobot or a semi-automatic welding cell.

An advantage of robotic welding, in addition to speed and repeatability, is the relatively quick ROI. To gain that, however, it’s important that the parts coming from upstream are consistent — gaps or poor fit-up can hinder the operation — and that there are no bottlenecks that would make the robot stay idle. An electronic CAD model of the part can help determine if a part lends itself to repeatability.

As with fixed welding automation and cobot welding, it’s imperative to have a welding operator involved with a robotic welding system. Parts need to be loaded and unloaded, and the robot requires programming. Robot integrators and manufacturers typically offer training to help ensure success.

Making the switch

Whether a company is a candidate for fixed welding automation, cobot welding or robotic welding, taking the time to carefully plan for the investment is important. Look to a trusted welding distributor, robot integrator or equipment provider for assistance and for help determining the expected payback.

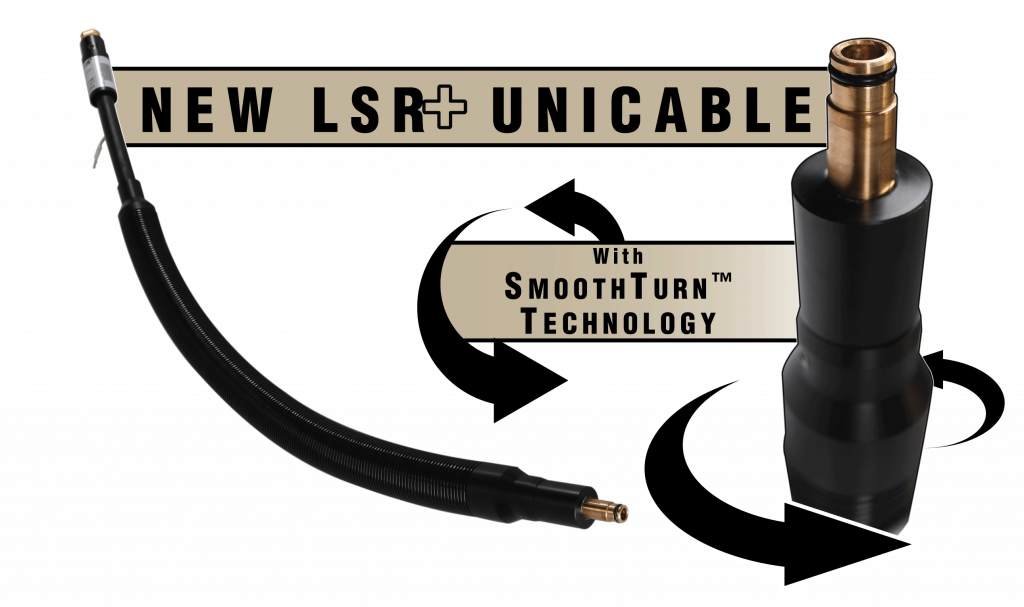

Product Improvement – LSR+ (Plus) Unicables

PRODUCT IMPROVEMENT –

LSR+ Unicables with SmoothTurn™ Technology

October 11, 2022

For use with TOUGH GUN® TA3 ThruArm® series robotic MIG guns, LSR+ (Low-Stress Robotic) unicables incorporate new SmoothTurn™ technology to maximize production uptime.

Conventional style unicables typically come with a connection that limits rotational capabilities and produces torsional stress in the cable. Unlike conventional unicables, the LSR+ incorporates a rotating power connection that reduces this stress during rotation. Additionally, a protective external conduit contributes to cable longevity by shielding components from harsh welding environments.

Stress Relieving Features

- SmoothTurn Technology reduces frictional forces on internal components increasing overall cable life up to 300%

- Enhanced electrical connections provide a more stable arc, resulting in less spatter and longer cable life

- Unique internal components improve support and bend radius of the cable during heavy robot articulation

MIG Welding Basics

MIG Welding Basics

Estimated reading time: 3 minutes

When it comes to MIG welding, it’s important for new welders to start with the basics to set a solid foundation for success. The process is generally forgiving, making it simpler to learn than TIG welding, for example. It can weld most metals and, as a continuously fed process, offers greater speed and efficiency than stick welding.

Welding safety

The very first consideration for new welders is welding safety. It is imperative to read and follow all labels and the equipment Owner’s Manuals carefully before installing, operating, or servicing welding equipment. Welders must wear proper eye protection to avoid arc flash burns and sparks. Always wear safety glasses and a welding helmet set to the appropriate shade level. Proper personal protective equipment attire is also critical to protect the skin from electric shock and burns. This includes:

- Leather shoes or boots.

- Leather or flame-resistant welding gloves

- Flame-resistant welding jacket or welding sleeves

Adequate ventilation is also an important safety factor. Welders should always keep their head out of the weld plume and be sure that the area in which they are welding has adequate ventilation. Some type of fume extraction may be needed. Fume extraction guns that remove the exhaust at the arc are also helpful, and are very efficient compared to floor or ceiling capture.

Welding transfer modes

Depending on base material and shielding gas, welders can weld in various welding transfer modes.

Short circuit is common for thinner materials and operates at lower welding voltage and wire feed speed, so it is slower than other processes. It also tends to produce spatter that requires post-weld cleaning, but overall, it is an easy process to use.

Globular transfer operates at higher wire feed speeds and welding voltages than short circuit and works for welding with flux-cored wire with 100% carbon dioxide (CO2) (see details on CO2 in next section). It can be used on 1/8-inch and thicker base materials. Like short-circuit MIG welding, this mode produces spatter, but it is a fairly fast process.

Spray transfer offers a smooth, stable arc, making it appealing to many new welders. It operates at high welding amperages and voltage, so it is fast and productive. It works well on base materials that are 1/8 inch or more.

Welding shielding gas

In addition to protecting the weld pool from the atmosphere, the type of shielding gas used for MIG welding impacts performance. Weld penetration, arc stability and mechanical properties depend on shielding gas.

Straight carbon dioxide (CO2) offers deep weld penetration but has a less stable arc and more spatter. It is used for short circuit MIG welding. Adding argon to a CO2 mixture allows for use of spray transfer for higher productivity. A balance of 75% argon and 25% is common.

Beyond the basics

Along with practice, knowing some key information can help new welders better understand the MIG welding process. It’s also important to be familiar with the equipment, including MIG welding guns and welding liners. Understanding how to select and maintain this equipment can go far toward establishing good welding performance, quality and productivity.

This is the first article in a three-part series on welding basics. Read article two, MIG Welding Glossary: Terms to Know and article three, MIG Welding Techniques: What to Know.

MIG Welding Glossary: Terms To Know

MIG Welding Glossary: Terms To Know

Estimated reading time: 3 minutes

Welders use MIG welding in many industries — fabrication, manufacturing, shipbuilding and rail to name a few. While it is a common process, it requires attention to detail, and it is helpful to know some key terms associated with it. As with any process, the better the understanding, the better the results.

Bird-nesting

The tangling of welding wire in the drive rolls of the wire feeder. This typically happens when the wire doesn’t have a smooth feeding path due to a liner being cut too short, the wrong size liner or tip being used, or incorrect drive roll settings. Resolve this issue by trimming the liner properly and ensuring that the feed path of the wire is as smooth and straight as possible.

Burnback

Occurs when the wire melts inside the contact tip before reaching the workpiece. It results from incorrect contact-tip-to-work distance (CTWD) — the distance between the end of the tip and the base metal — or a too-slow wire feed speed (WFS). It can also be caused by incorrectly trimmed liner and incorrect parameters. Remedy the problem by increasing WFS, adjusting CTWD, trimming the liner according to the manufacturer’s recommendation and modifying weld parameters.

Deposition rate

Refers to how much filler metal is deposited into a weld joint over a specified period of time, measured in pounds or kilograms per hour (lbs/hr or kg/hr).

Discontinuity

A flaw in the structure of a weld that does not pose a risk of failure. It differs from a weld defect that can affect the integrity of a weld once in service.

Duty cycle

Refers to the percentage of time in a 10-minute period a gun can be used at a specific amperage (arc-on time) without becoming too hot to handle or overheating. A gun’s duty cycle is affected by the type of shielding gas being used for welding. For example, a MIG gun may be rated at 100% duty cycle with 100% CO2 shielding gas, meaning it can weld the entire 10 minutes without issues; or it could have a gun rating of 60% duty cycle with mixed gases.

Electrode extension

The distance the welding wire extends from the end of the contact tip to where the wire melts. As electrode extension increases, amperage decreases, which reduces joint penetration. Also commonly referred to as tip-to-workpiece distance.

Heat-affected zone

Often referred to as HAZ, it is the portion of the base material surrounding the weld that hasn’t melted but has had its properties changed at a microstructure level due to the heat input. Cracking can occur here.

Incomplete fusion

Also called lack of fusion, it occurs when the weld fails to fuse completely with the base material or a previous weld pass in multi-pass welding. Typically, it is the result of an incorrect MIG gun angle.

Porosity

A cavity-like discontinuity that occurs when gas becomes trapped in the weld upon solidification of the molten weld pool. It is most often caused by poor shielding gas coverage or base material contamination.

Weld penetration

Refers to the distance the weld fuses below the surface of the base material. Incomplete weld penetration occurs when the weld doesn’t completely fill the root of the joint.

This is the second article in a three-part series on welding basics. Read article one, MIG Welding Basics and article three, MIG Welding Techniques: What to Know.

MIG Welding Techniques: What To Know

MIG Welding Techniques: What To Know

Estimated reading time: 2 minutes

Understanding some proper techniques for MIG welding can help welders gain good weld quality and avoid the frustration and cost of rework. Everything from proper positioning of the MIG welding gun to travel angle and travel speed can make an impact.

Consider these four recommended techniques:

- While welding, hold the MIG welding gun straight, using both hands to steady it and keeping them at or just below elbow height. This approach not only makes it easier to make a quality weld, but it also helps improve ergonomics. That is particularly important for welders welding for a long period of time, so they can avoid injury.

- Welders should keep a contact-tip-to-work distance (CTWD) of approximately 3/8 to 1/2 inch for short-circuit welding and around 3/4 inch for spray transfer MIG welding.

- Use the proper travel angle. When push welding, welders should hold the gun at a 10-degree angle. This technique creates a wide bead with less joint penetration. For a pull technique, welders use the same angle, pulling the gun toward their body. This results in more penetration and a narrow weld bead.

- Maintain a consistent travel speed with the wire at the leading edge of the weld pool. Too fast of a travel speed creates a narrow bead that may not fully tie in at the weld toes and may lack proper penetration. Traveling too slow creates a wide weld, also with inadequate penetration. Both too slow and too fast travel speeds can cause burn-through on thin base metals.

As with any welding process, practice is a large part of MIG welding success. Along with good techniques, it’s also important to properly prepare and clean the base material before welding and to maintain the MIG welding gun and consumables properly. This can reduce downtime for addressing equipment issues or troubleshooting weld defects and problems such as poor wire feeding.

This is the third article in a three-part series on welding basics. Read article one, MIG Welding Basics and article two, MIG Welding Glossary: Terms to Know.

Solving Common Causes of Welding Porosity

Solving Common Causes of Welding Porosity

Estimated reading time: 7 minutes

Porosity, cavity-type discontinuities formed by gas entrapment during solidification, is a common but cumbersome defect in MIG welding and one with several causes. It can appear in semi-automatic or robotic applications and requires removal and rework in both cases — leading to downtime and increased costs.

The major cause of porosity in steel welding is nitrogen (N2), which gets involved in the welding pool. When the liquid pool cools down, the solubility of N2 is significantly reduced and N2 comes out of the molten steel, forming bubbles (pores). In galvanized/galvanneal welding, evaporated zinc can be stirred into the welding pool, and if there is not enough time to escape before the pool solidifies, it forms porosity. For aluminum welding, all porosity is caused by hydrogen (H2), by the same way as N2 works in steel.

Welding porosity can appear externally or internally (often called sub-surface porosity). It can also develop at a single point on the weld or along the entire length, resulting in weak welds.

Knowing how to identify some key causes of porosity and how to quickly solve them can help improve quality, productivity and the bottom line.

Poor Shielding Gas Coverage